Nano composite hydrogen-storing material and preparing method

A hydrogen storage material and nanocomposite technology, applied in chemical instruments and methods, hydrogen, and other chemical processes, etc., can solve the problems of poor kinetics, high storage and desorption temperatures, and achieve simple preparation process, high hydrogen storage capacity, The effect of excellent comprehensive hydrogen storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

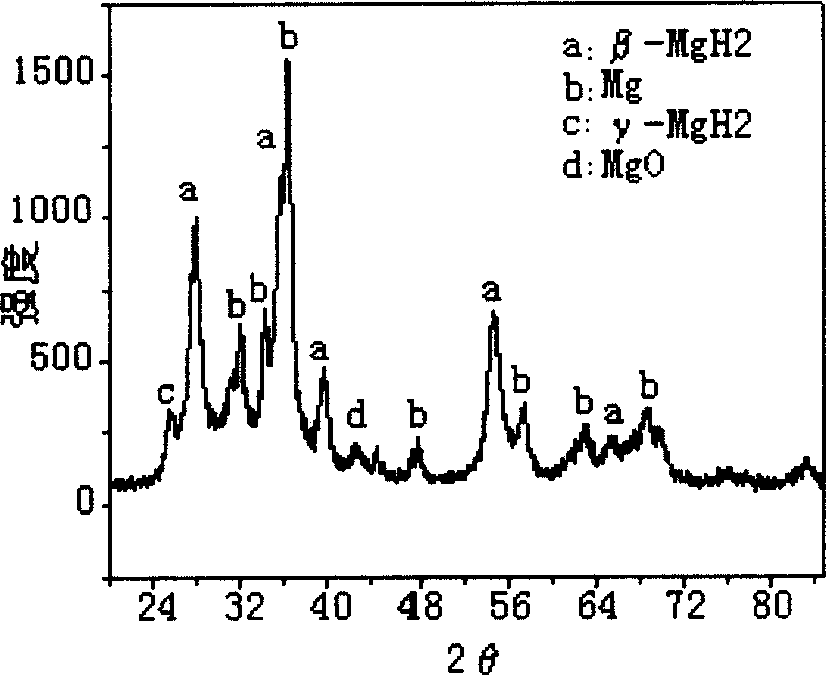

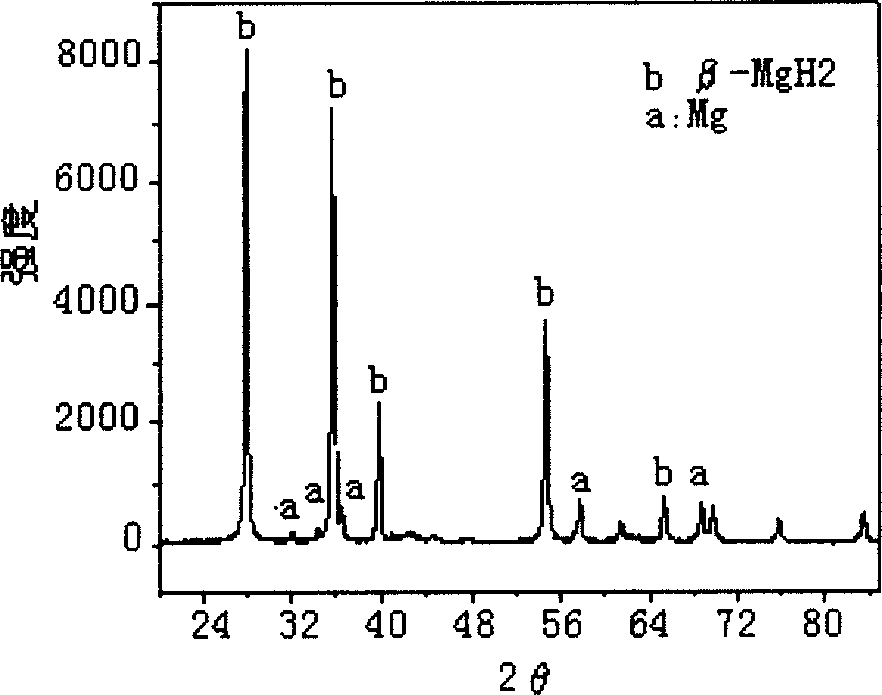

[0029] Purified single-walled carbon nanotubes have a purity of about 90% and a tube diameter of 1-2nm. Then the purified single-walled carbon nanotubes were mixed into the magnesium hydride powder prepared by reaction ball milling and mixed evenly (single-walled carbon nanotubes: MgH 2 =5:95, percent by weight), and then high-energy ball milling was carried out under the protection of argon, the ball-to-material ratio was 20:1, and the ball milling time was 10 hours. The hydrogen storage performance of the prepared nanocomposites was tested by volume method after desorption (such as Figure 4 with 5 Shown), the hydrogen pressure is 2MPa. At 573K, the hydrogen storage capacity is 6.67wt% in 600 seconds; at 473K, it can absorb 5.47wt% hydrogen in one hour, and the maximum hydrogen absorption rate is 6.35wt%; even at 423K, it can absorb 2.5% hydrogen in one hour. wt%, and the maximum hydrogen absorption can reach 4.8wt%. At 623K, the hydrogen desorption capacity of the prepa...

Embodiment 2

[0031] Purified single-walled carbon nanotubes have a purity of about 90% and a tube diameter of 1-2nm. Then the purified single-walled carbon nanotubes were mixed into the magnesium hydride powder prepared by reaction ball milling and mixed evenly (single-walled carbon nanotubes: MgH 2 =10:90, percent by weight), and then high-energy ball milling was carried out under the protection of argon, the ball-to-material ratio was 20:1, and the ball-milling time was 30 hours. The hydrogen storage performance of the prepared nanocomposites was tested by volume method after desorption (such as Figure 4 with 5 Shown), the hydrogen pressure is 2MPa. At 573K, the hydrogen storage capacity is 6.5wt%; at 473K, the hydrogen storage capacity is 6.0wt%.

Embodiment 3

[0033] Mix unpurified single-walled carbon nanotubes (containing Fe, Co, Ni catalysts) into magnesium hydride powder prepared by reaction ball milling and mix evenly (single-walled carbon nanotubes: MgH 2 =1:99, percent by weight), and then high-energy ball milling was carried out under the protection of argon, the ball-to-material ratio was 20:1, and the ball-milling time was 20 hours. The hydrogen storage performance of the prepared nanocomposites was tested by volume method after desorption (such as Image 6Shown), the hydrogen pressure is 2MPa. At 573K, the hydrogen storage capacity is 5.5wt%; at 473K, the hydrogen storage capacity reaches 4.6wt% within 10 minutes, and the maximum hydrogen storage capacity reaches 5.3wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com