Environmental-protection type coal-saving surface-removing dust-reducing emulsion and its preparing method

An environmentally friendly and dust-reducing technology, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of heavy economic burden, large one-time investment, low cost of use, etc., to reduce pollutant emissions, improve combustion efficiency, and greatly reduce environmental protection. effect of meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

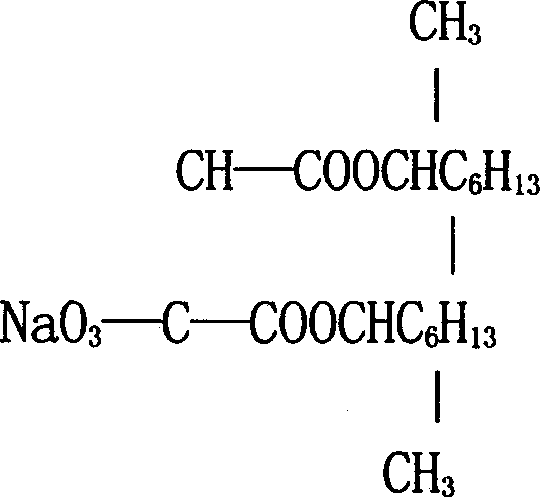

[0057] Embodiment 1: environment-friendly, coal-saving, sulfur-removing and dust-reducing emulsion, its composition weight ratio is successively distilled water 75.9%, maleic acid di-secondary octyl sodium 0.4%, light hydrocarbon 2.5%, sodium tetraborate 0.3%, 15% of sodium nitrate, 3% of sodium chlorate, 0.5% of sodium peroxide, 1% of sodium dichromate, 1% of sodium carbonate, and 0.4% of ammonium perchlorate are successively added to the high-speed stirring reaction kettle for heating and carrying out compound reaction, and then Enter the high-speed jet pulverizer for shearing and reciprocating cycle shearing and crushing, and mix a stable emulsion-like environmental protection coal-saving, sulfur-removing and dust-reducing agent. When using it, add water at a ratio of 1:10, and mix 11% emulsion-water mixture per ton of raw coal for use. When the temperature is increased by 130°C, the blackness of the flue gas is reduced by 1 Ringelmann level, the coal saving rate reaches 10%...

Embodiment 2

[0058] Embodiment 2: environment-friendly, coal-saving, sulfur-removing and dust-reducing emulsion, its composition weight ratio is successively distilled water 66.2%, maleic acid di-second-octyl sodium 1.0%, light hydrocarbon 3.5%, sodium tetraborate 0.4%, 18% of sodium nitrate, 4% of sodium chlorate, 1% of sodium peroxide, 2.5% of sodium dichromate, 2.0% of sodium carbonate and 1.4% of ammonium perchlorate are added successively to the high-speed stirring reaction kettle for heating and carry out compound reaction, and then Enter the high-speed jet pulverizer for shearing and reciprocating cycle shearing and pulverization, and mix a stable emulsion-like environmental protection, coal-saving, sulfur-removing and dust-reducing agent. When using, add water at a ratio of 1:10, add 11% emulsion water mixture to each ton of raw coal, increase the furnace temperature by 150°C, reduce the blackness of flue gas by 2 levels, save coal by 15%, and reduce sulfur dioxide emissions Volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com