Light-emitting element device, light-receiving element device, optical device, fluoride crystals, production method of fluoride crystals, and crucible

A technology for light-receiving elements and light-emitting elements, applied in optical elements, chemical instruments and methods, optics, etc., can solve the problems of reduced luminous efficiency, high light energy, reduced reliability, etc., and achieves improved decomposition resistance, transparent The effect of good light rate and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Embodiment 1 (add the CaF of Ti 2 )

[0109] Manufacture of titanium-added calcium fluoride.

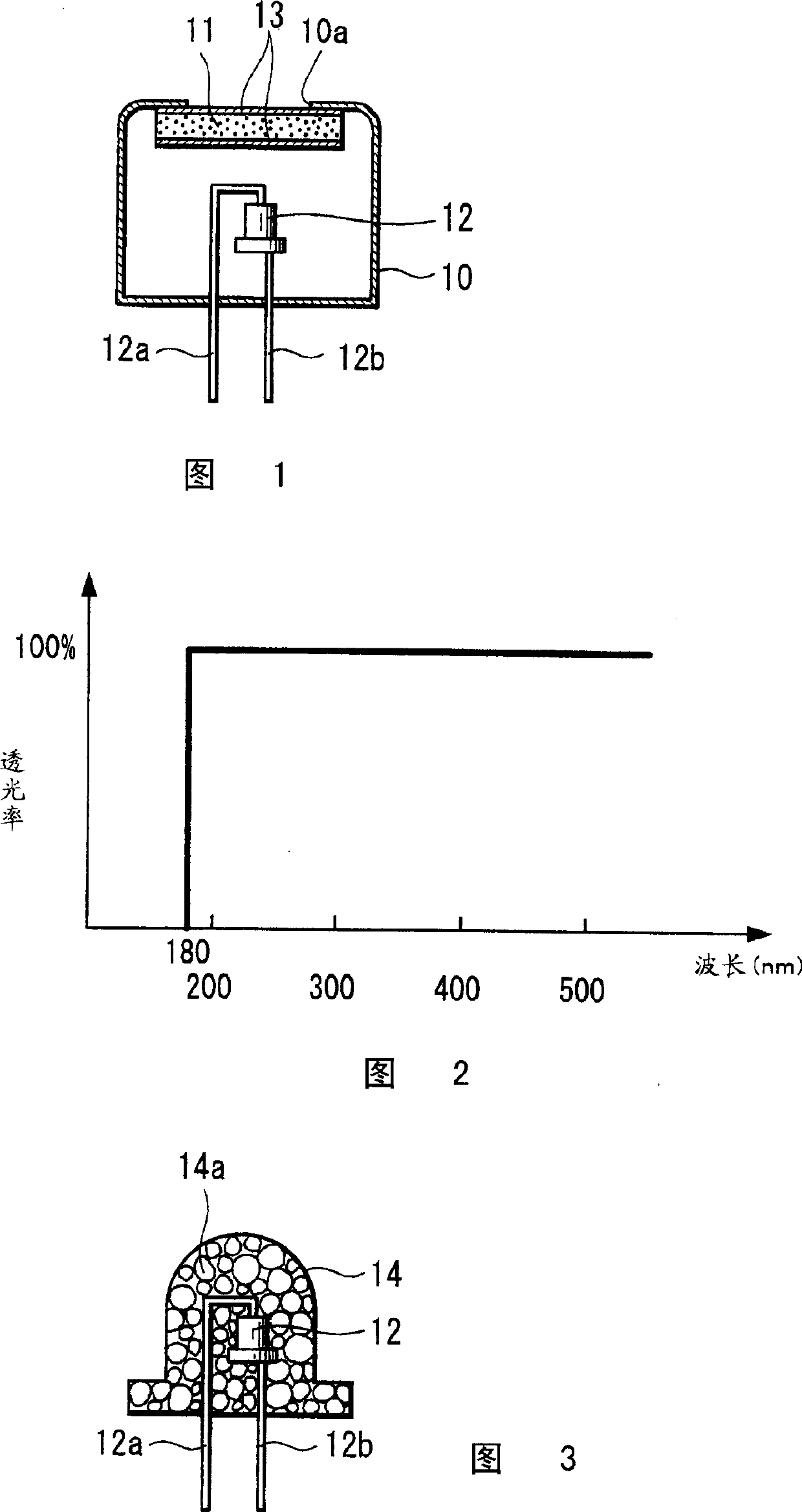

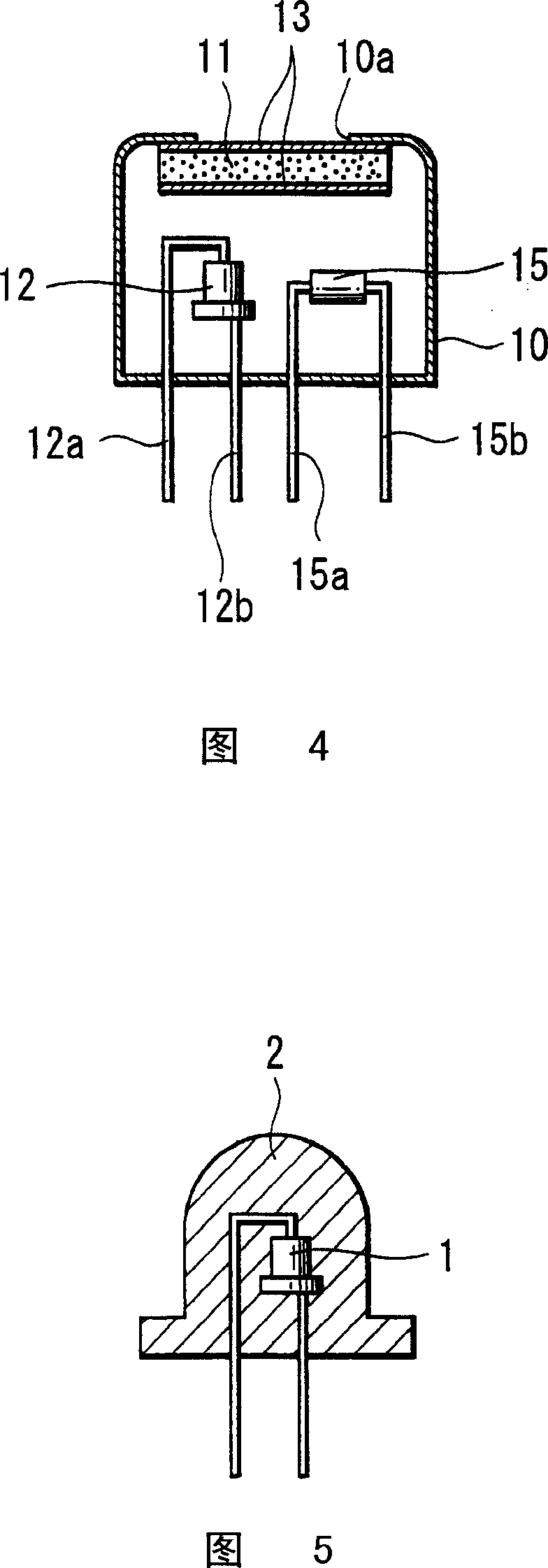

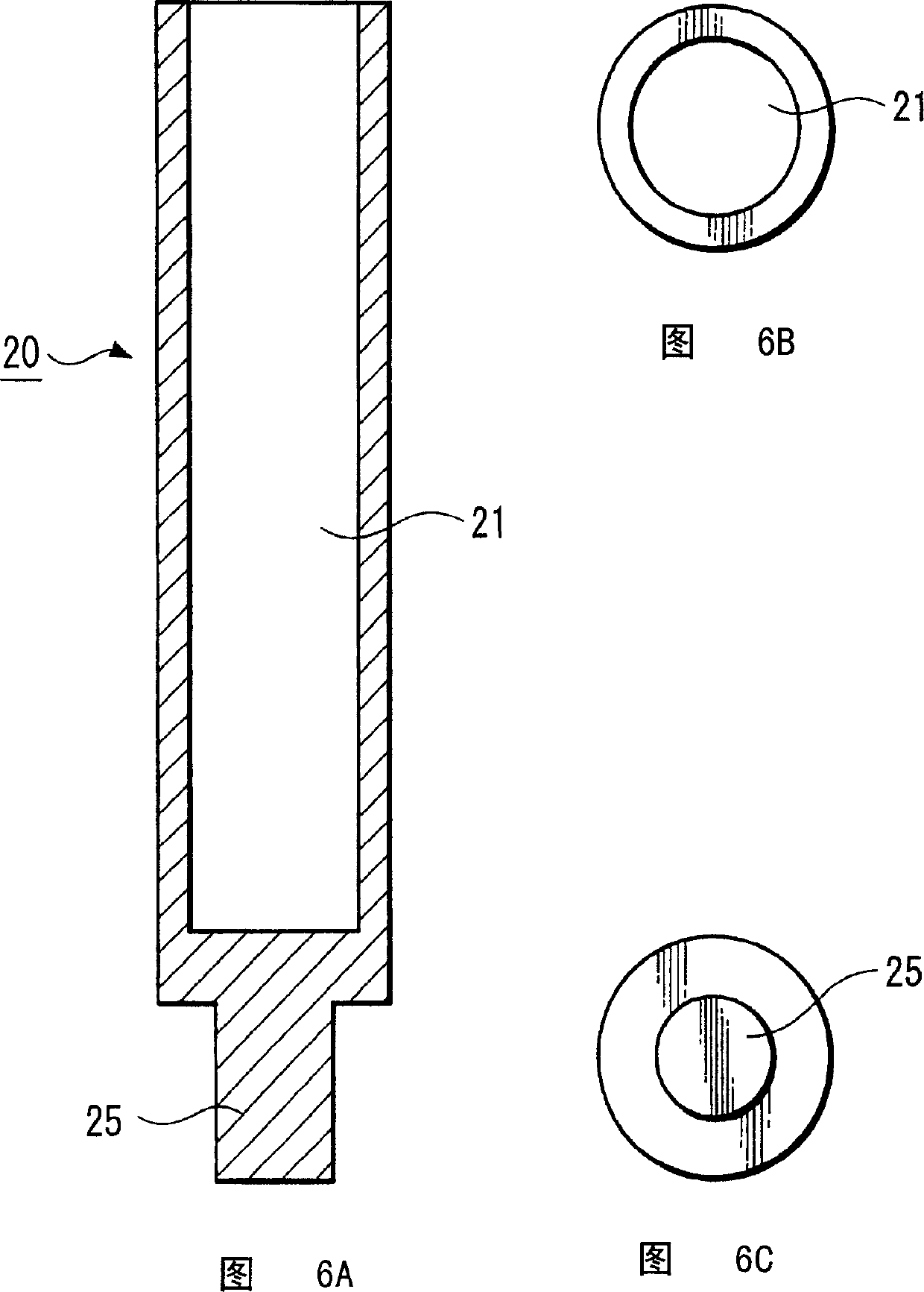

[0110] A method for producing titanium-added calcium fluoride will be described. Figures 6A, 6B, and 6C show graphite crucibles for producing fluoride crystals of the present invention. The diameter of the cavity portion 21 is 1 inch (2.54 cm). Fill the graphite crucible with CaF 2 Raw material powder, which is inserted into a vertical Bridgman furnace. Add CaF to graphite crucible 2 0.1 mol% Ti was added to the raw material to form crystals. When determining the crystal orientation, place the seed crystal on the bottom of the crucible. When the crystal orientation is not determined, it is not necessary to use a seed crystal. After that, a 1×10 -6 The vacuum is around Torr, and the electric furnace is heated up to 1450°C while maintaining the vacuum. In this state, it is kept warm for about 2 hours to melt and stabilize the internal raw materials according to the temp...

Embodiment 2

[0115] (Add TiF 3 CaF 2 )

[0116] Manufacture of calcium fluoride added with titanium fluoride.

[0117] Adding CaF to the graphite crucible 2 Add 0.1mol% TiF as raw material 3 , other are identical with embodiment 1 except this.

[0118] In addition, calcium fluoride to which 2 mol% of titanium fluoride was added and calcium fluoride to which 2 mol% of titanium fluoride+0.5 mol% of zinc fluoride were added were produced by the same method as in Example 1.

Embodiment 3

[0120] (Add SrF 2 CaF 2 )

[0121] Manufacture of calcium fluoride doped with strontium fluoride.

[0122] Adding CaF to the graphite crucible 2 Add 0.1mol% SrF as raw material 2 , other are identical with embodiment 1 except this.

[0123] In addition, calcium fluoride added with 0.2 mol%, 0.6 mol%, or 2 mol% of strontium fluoride, and calcium fluoride added with 2 mol% of strontium fluoride + 0.5 mol% of zinc fluoride were produced by the same method as in Example 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com