Method of stripping cyanide and valuable metal on resin with ultrasonic

A valuable metal and cyanide technology, applied in the direction of improving process efficiency, can solve the problems of no gold ore cyanide solution, difficult desorption, poor effect, etc., to improve comprehensive recovery rate, improve desorption efficiency, and speed up transmission The effect of mass velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

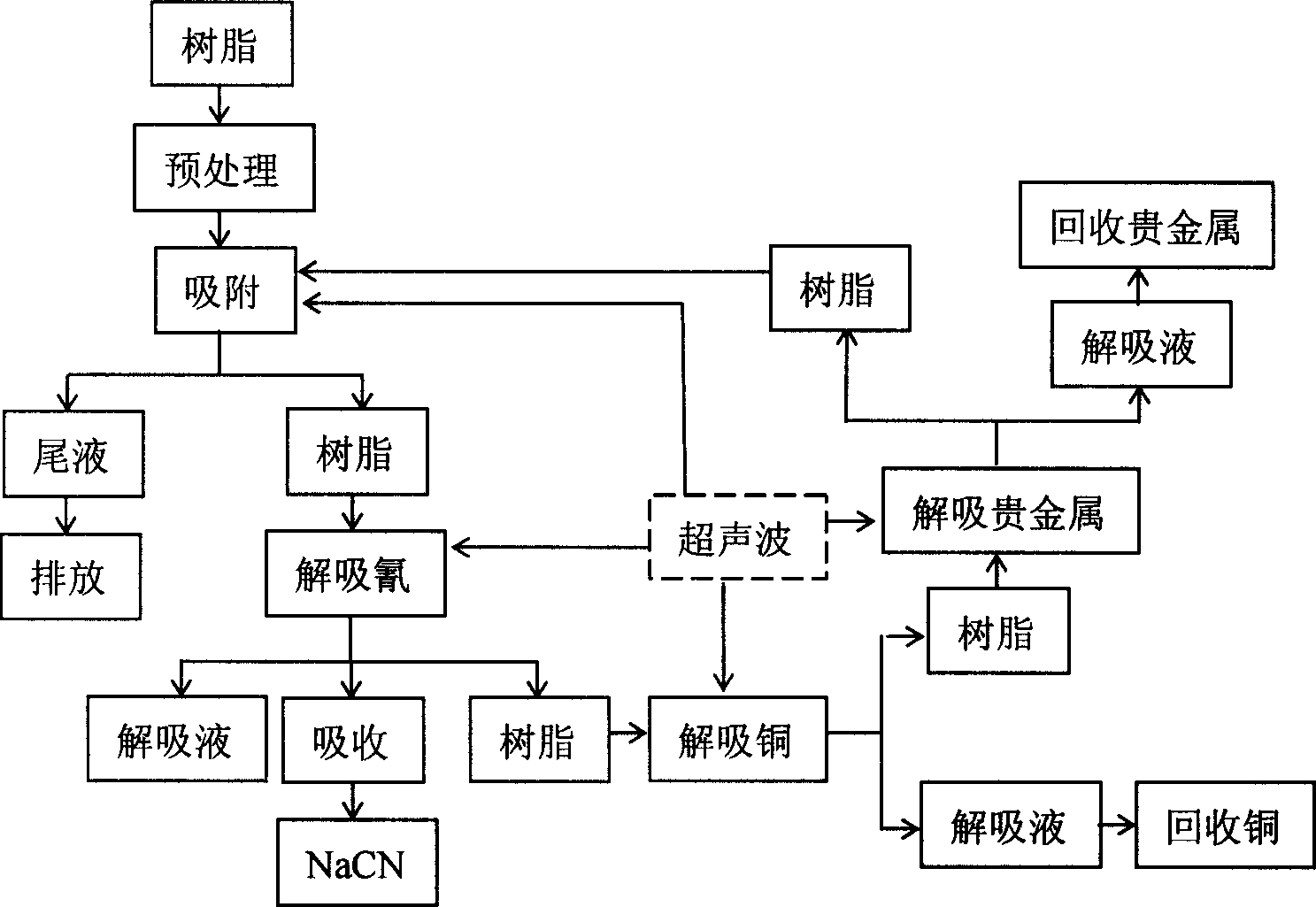

Image

Examples

Embodiment

[0021] Raw materials: gold extraction tail liquid from a gold smelter, its main components are: total cyanide 134.2mg / L, zinc 60.3mg / L, copper 630.2mg / L, gold 0.1mg / L, silver 0.23mg / L. Under normal temperature conditions, the volume ratio of resin to solution is: 1 / 15. After adsorption, the resin adsorption rate is 95.3% of total cyanide, 99.2% of zinc, 99.1% of copper, 95.3% of iron, and 99.8% of precious metal gold and silver. The loaded resin is desorbed step by step at room temperature in the desorption reactor, and the power used in the process is 40KW / dm 3 , Ultrasonic frequency is 10KHz for process strengthening. First use 2.5% sulfuric acid solution to desorb cyanide and zinc. The volume ratio of resin to solution is 1 / 3. After absorption by 10% sodium hydroxide solution, a sodium cyanide solution of about 10g / L can be obtained, which can be returned to the leaching system. Get a zinc sulfate solution of about 300mg / L, which can be obtained by distillation after multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com