Structure, constitution of electrocatalytic hydrogen evolution electrode and manufacturing method thereof

A technology of a hydrogen evolution electrode and a manufacturing method, which is applied in the field of electrocatalytic hydrogen evolution, can solve the problems of short life, poor electrode stability, and easy poisoning of the electrode, and achieve the effects of long life, stable electrode performance, and high hydrogen evolution catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 adopts chemical method to manufacture activated carbon powder to carry metallic nickel catalyst powder, and make electrocatalytic hydrogen evolution electrode with it

[0025] 1) Manufacture of catalyst powder. Weigh 3 grams of activated carbon powder, add it to 15 ml of isopropanol, and ultrasonically disperse it for 30 minutes, then adjust the pH value of the solution to 9.0 with ammonia water. Add about 20ml of 0.5M NiCl dropwise to the solution 2 solution. Afterwards, excess hydrazine hydrate was added to the solution, and the solution was stirred at a constant temperature of 60° C. until the nickel ions in the solution reacted completely to form nickel metal. After the reaction is completed, the reaction product is fully washed with water once, and dried to obtain the activated carbon powder-supported metal nickel catalyst powder.

[0026] 2) Fabricate the catalytic layer. According to the weight ratio of 2:1, respectively weigh the activated carbo...

Embodiment 2

[0030] Example 2 Catalyst Ni-Co alloy powder is prepared by a metallurgical method and used to make an electrocatalytic hydrogen evolution electrode

[0031] 1) Manufacture Ni-Co alloy catalyst powder. Select an appropriate amount of metallic nickel and metallic cobalt according to the composition of the Ni-Co alloy, put them into a smelting furnace to melt and fully mix them uniformly. After that, the molten Ni-Co alloy liquid is solidified into Ni-Co alloy powder by using a high-speed liquid jet method to obtain the catalyst powder.

[0032] 2) Fabricate the catalytic layer. Weigh Ni-Co alloy powder, graphite powder and carboxymethyl cellulose emulsion respectively according to the weight ratio of 20:1:5, mix thoroughly and uniformly, and press at 50°C to form a film with a thickness of about 1 mm to obtain a catalytic layer.

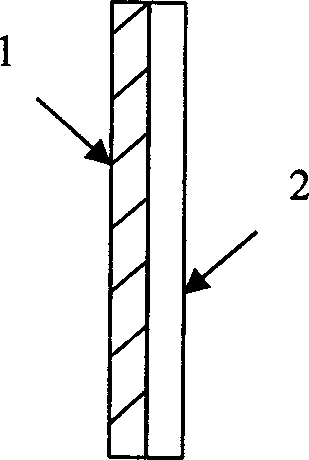

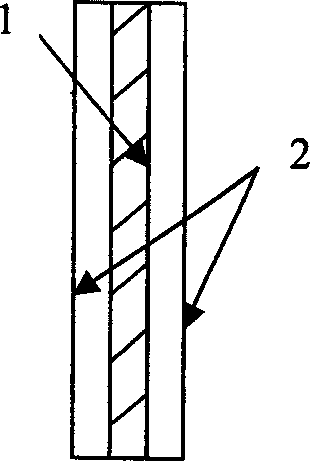

[0033] 3) Fabrication of electrocatalytic hydrogen evolution electrodes. A porous stainless steel plate is used as the current collector layer 1, ...

Embodiment 3

[0036] Example 3 The method of physical vapor deposition (PVD method for short) is used to prepare carbon black powder loaded Mo-Co alloy catalyst powder, and use it to make electrocatalytic hydrogen evolution electrode

[0037] 1) Manufacture of catalyst powder. Select appropriate amount of metal nickel and metal cobalt according to the composition of the Ni-Co alloy, put them into a tungsten boat and place them in the vacuum chamber of the PVD equipment. At the same time, put the carbon black powder into the vacuum chamber of the PVD equipment. The metal nickel and metal cobalt in the tungsten boat are melted and gasified by electrification, so that they are evenly deposited on the surface of the carbon black powder, and the carbon black powder is prepared to carry Mo-Co alloy catalyst powder.

[0038] 2) Fabrication of electrocatalytic hydrogen evolution electrodes. According to the weight ratio of 5:5:20, weigh carbon black powder loaded Mo-Co alloy catalyst powder, acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com