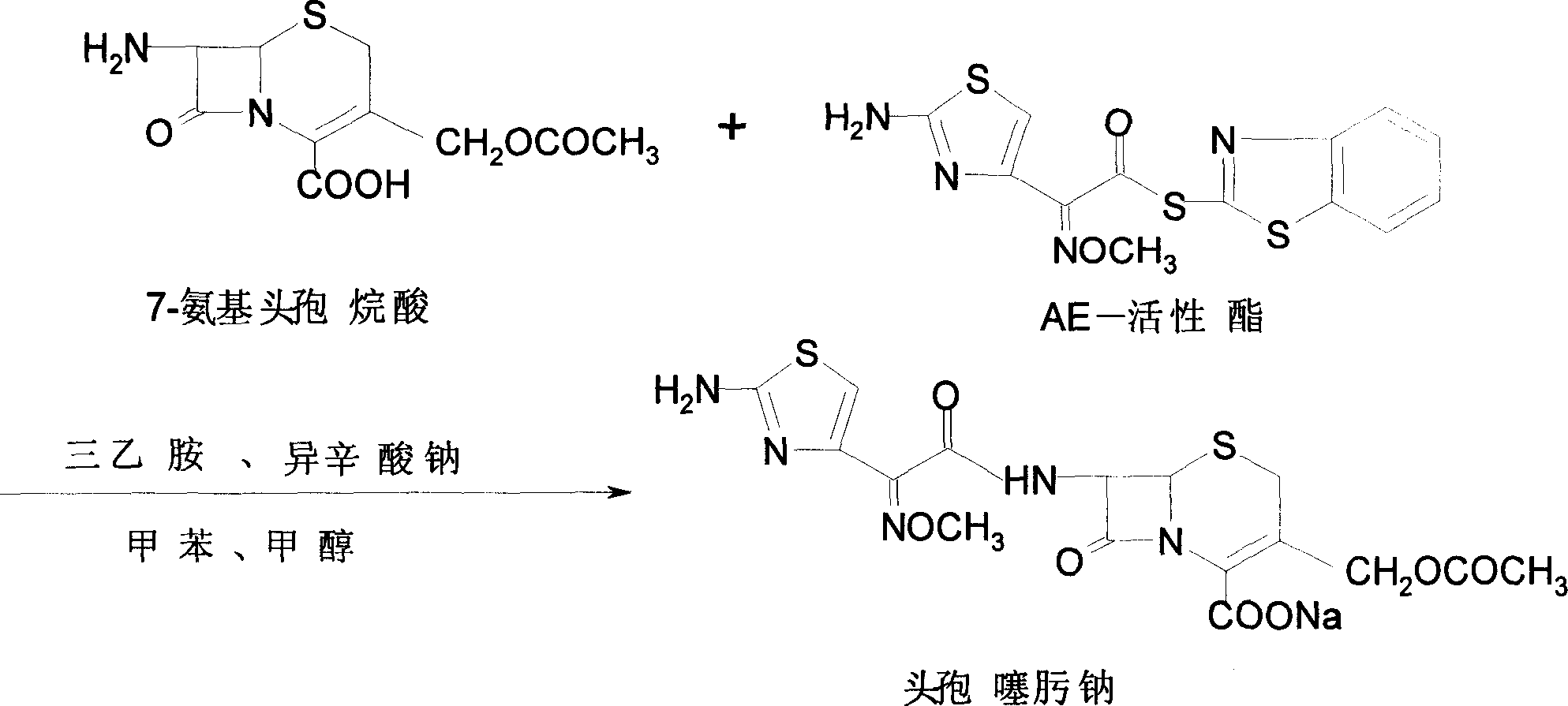

One-step preparation process of aseptic cefotaxime sodium for injection

A cefotaxime sodium and preparation technology, applied in the field of compound preparation, can solve problems such as large amount of solvent used, poor crystallization condition, affecting product quality, etc., achieve reduced amount of solvent used, low production cost, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation technology of cefotaxime sodium of the present invention is as follows:

[0025] Add 120ml of toluene and methanol with a volume ratio of 1:1 to form a mixed solvent, 20ml of triethylamine, cool down to 5°C, add 20g of 7-ACA, 28g of AE-active ester, and keep at 5°C for 60 Minutes, after the reaction is clarified, add 3 milliliters of concentrated hydrochloric acid, add sodium isooctanoate solution salt forming agent and 0.1 g sodium bisulfite antioxidant at room temperature, react for 10 minutes, then seed and grow crystals for 30 minutes, and then add toluene dropwise 150ml, the temperature of the dropwise addition of toluene is controlled at 20°C, and the drop is completed in 2 hours. After the drop is completed, the crystal is grown for 30 minutes and the material is discharged. The mixture of 50ml ethyl acetate and 5ml absolute ethanol is used to wash the cake, and then add the cake Stir and wash in the mixture of 140ml acetone and 6ml water for 30 m...

Embodiment 2

[0028] Add 120ml of toluene and methanol with a volume ratio of 1:1 to form a mixed solvent, 20ml of triethylamine, cool down to 7°C, add 20g of 7-ACA, 28g of AE-active ester, and keep it at 7°C for 63 Minutes, add 3ml of concentrated hydrochloric acid after the reaction is clarified, add a salt-forming agent (13 grams of sodium isooctanoate dissolved in a mixture of 15ml of toluene and 15ml of methanol) at room temperature, 0.1g of sodium bisulfite, then add dropwise toluene to slightly When the crystal is cloudy, grow the crystal for 30 minutes, and then add the remaining toluene dropwise. The temperature of the dropwise addition of toluene is controlled at 22°C, a total of 120ml is added, and the drop is completed within 1.5 hours. Wash the cake with a mixture of ester and 5ml of isopropanol, then add the cake to a mixture of 140ml of acetone and 6ml of water, stir and wash for 20 minutes, then discharge the cake, then wash the cake with a small amount of acetone, wet materi...

Embodiment 3

[0030] Add 120ml of toluene and methanol at a volume ratio of 1:0.8 to the three-neck flask to form a mixed solvent, 20ml of triethylamine, cool down to 4°C, add 20g of 7-ACA, 28g of AE-active ester, and keep at 5°C for 65 Minutes, add 1g of trichloromethyl chloroformate after the reaction is clarified, add a salt-forming agent (13 grams of sodium isooctanoate dissolved in 30ml of mixed solvent) at room temperature, 0.1g of sodium bisulfite, add crystal seeds to grow crystals for 30 minutes Minutes, then add the remaining toluene dropwise, the temperature of the dropwise addition of toluene is controlled at 18°C, a total of 120ml is added, and the drop is completed within 1.8 hours. Wash the cake with a mixture of ethanol, then add the cake to a mixture of 150ml acetone and 6ml water, stir and wash for 25 minutes, then discharge the cake, wash the cake with a small amount of acetone, and dry the wet product in vacuum at 50 degrees .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com