Zero discharge and circular utilization method of industrial effluent in regeneration treatment

An industrial sewage, zero-discharge technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, infiltration/dialysis water/sewage treatment, etc. and other problems, to achieve the effect of reducing treatment costs, saving investment costs, and achieving zero emissions and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

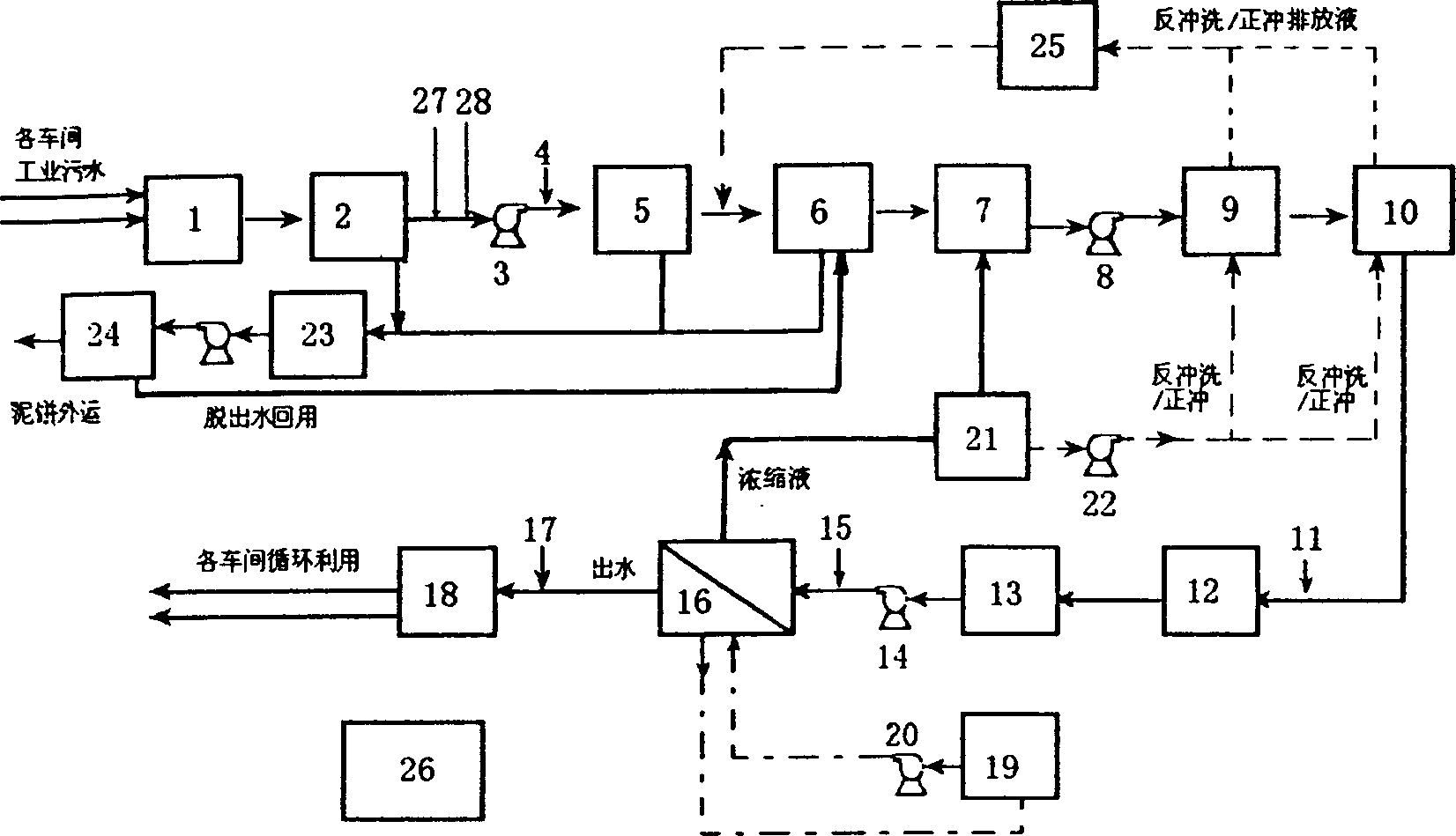

Method used

Image

Examples

Embodiment

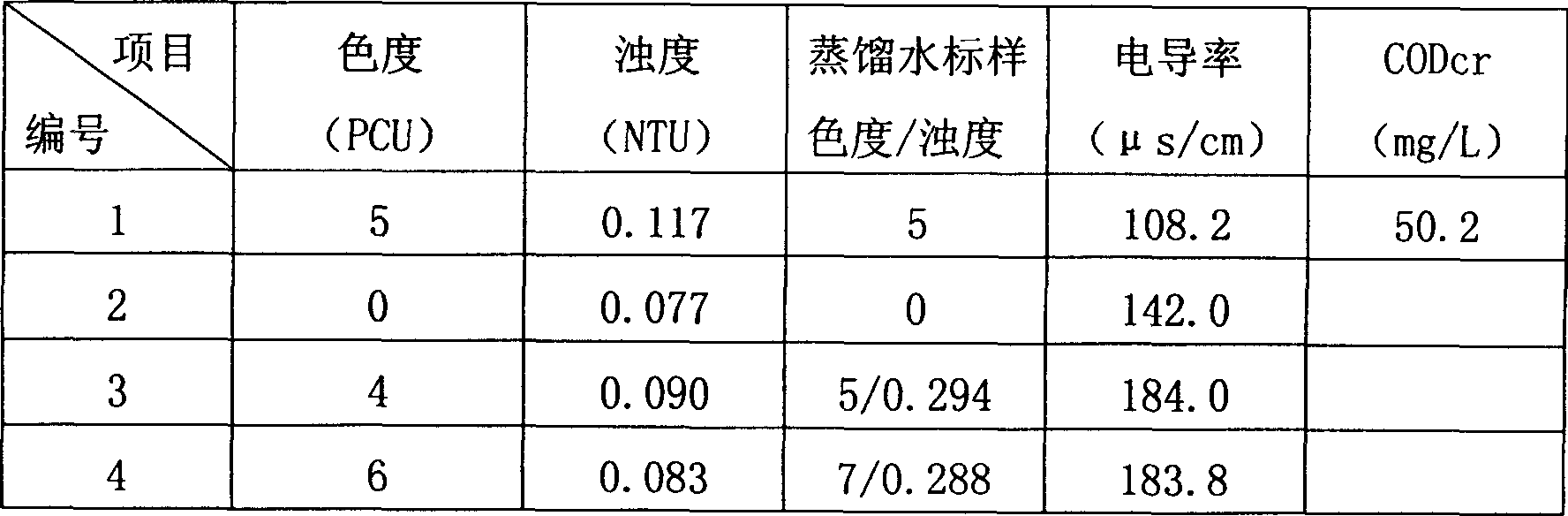

[0044] The present invention is further explained by taking the successful application in a large paper-making enterprise as an example: the large-scale paper-making enterprise draws water from inland rivers every day, and through sedimentation and purification treatment, it becomes clear water for production, and the quality requirements of clear water are chromaticity≤12PCU, turbidity≤1.5NTU (Chromaticity ≤ 15PCU, turbidity ≤ 5NTU higher than drinking water requirements). Clean water is transformed into about 30,000 tons of high-concentration industrial sewage after being used in various production workshops, in which the chemical oxygen demand (COD) and suspended solids (SS) are as high as 3000-5000mg / L. It can meet the national discharge standard (the average chromaticity and turbidity of wastewater are 82PCU and 11NTU respectively), but it cannot be recycled because it cannot meet the quality requirements of clean water for enterprise production. It can only be discharged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com