Water soluble paint for automobile

A water-soluble paint, automotive technology, applied in coatings, latex paints, etc., can solve problems such as polluting the environment and affecting operating conditions, and achieve the effect of smooth and bright coating film, convenient use and wide curing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

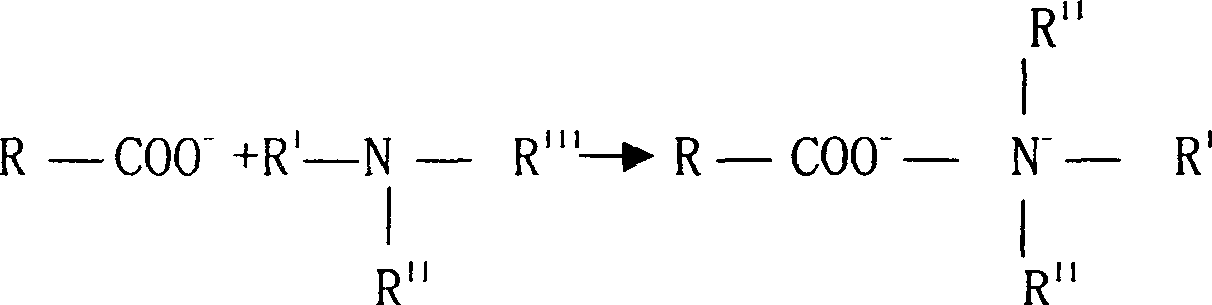

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, a kind of implementation product of the present invention adopts following raw material and technique to make:

[0044] 1. Raw material formula

[0045] Butanol 60kg

[0046] Deionized water 400kg

[0047] Methacrylic acid 60kg

[0048] Isooctyl methacrylate 155kg

[0049] Acrylamide 130kg

[0050] Di-tert-butyl peroxide 9kg

[0051] Epoxy E-44 255kg

[0052] Triethylamine 15kg

[0053] Styrene 80kg

[0054] Butyl acrylate 160kg

[0055] 2. Process flow

[0056] According to the above formula, butanol, methacrylic acid, isooctyl methacrylate, acrylamide, acrylic resin, styrene and epoxy E-44 are mixed into a single agent, and deionized water with a suitable boiling point is used as a solvent Polymerize at a polymerization concentration of 60%, take di-tert-butyl peroxide as an initiator, add the above-mentioned mixed single agent at a uniform speed, raise the temperature to reflux, react at this temperature for 5 hours, then cool down to 120 degr...

Embodiment 2

[0058] Embodiment 2, another implementation product of the present invention adopts following raw material and process to make:

[0059] 1. Raw material formula

[0060] Butanol 90kg

[0061] Deionized water 600kg

[0062] Methacrylic acid 90kg

[0063] Isooctyl methacrylate 185kg

[0064] Acrylamide 160kg

[0065] Benzoyl Peroxide 12kg

[0066] Epoxy E-44 285kg

[0067] Triethylamine 18kg

[0068] Acrylic 100kg

[0069] Ethyl acrylate 200kg

[0070] 2. Process flow

[0071] According to the above formula, butanol, methacrylic acid, isooctyl methacrylate, acrylamide, ethyl acrylate, acrylic acid and epoxy E-44 are mixed into a single agent, and deionized water with a suitable boiling point is used as a solvent in the Polymerize at a polymerization concentration of 65%, take benzoyl peroxide as an initiator, add the above-mentioned mixed single agent at a uniform speed, heat up to reflux, react at this temperature for 6 hours, then cool down to 140 degrees, and add trie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com