Alpha-PbFz nano-rod, strip or piece and its manufacturing method and use

A nano-strip, nano-rod technology, applied in chemical instruments and methods, luminescent materials, lead halide and other directions, to achieve the effects of easy availability of raw materials, simple raw materials and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

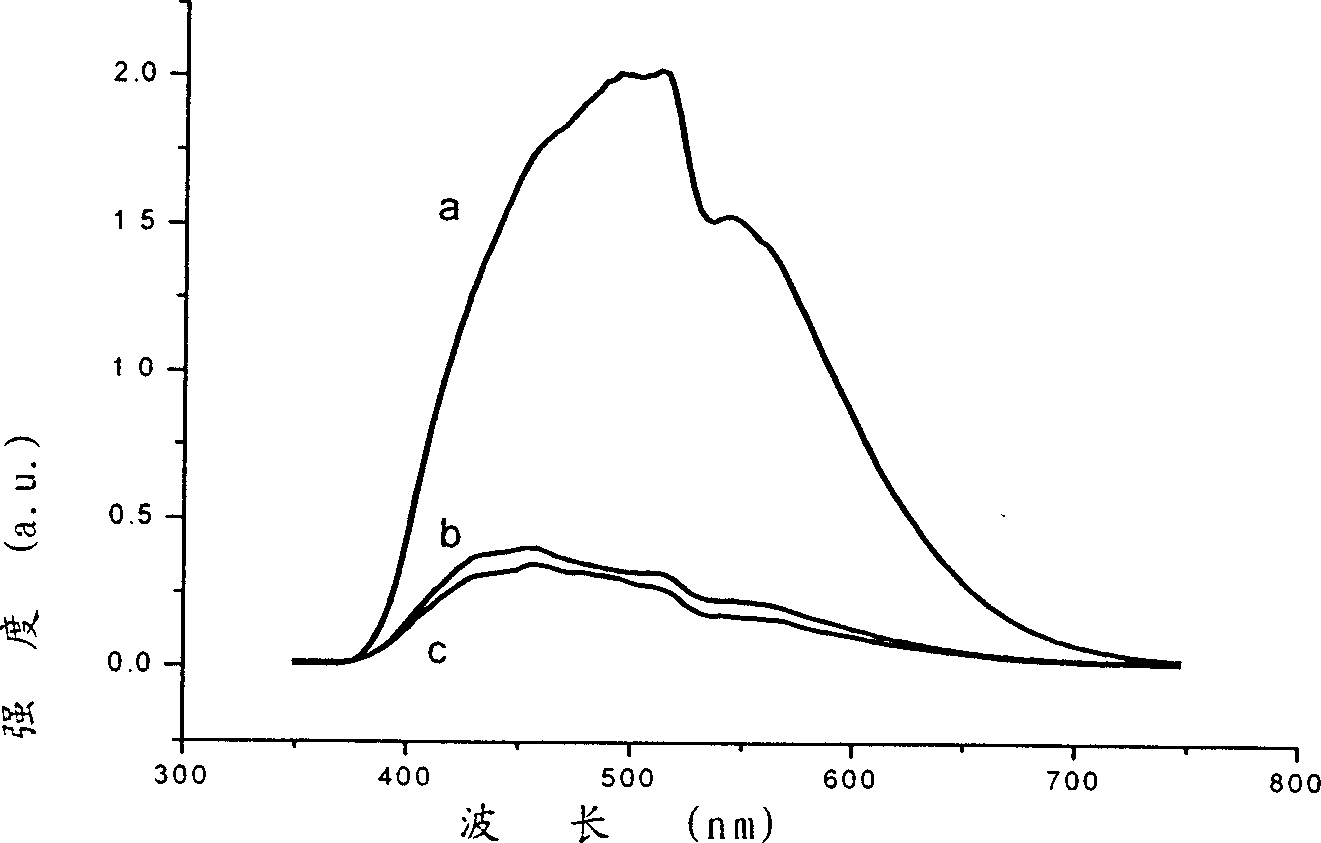

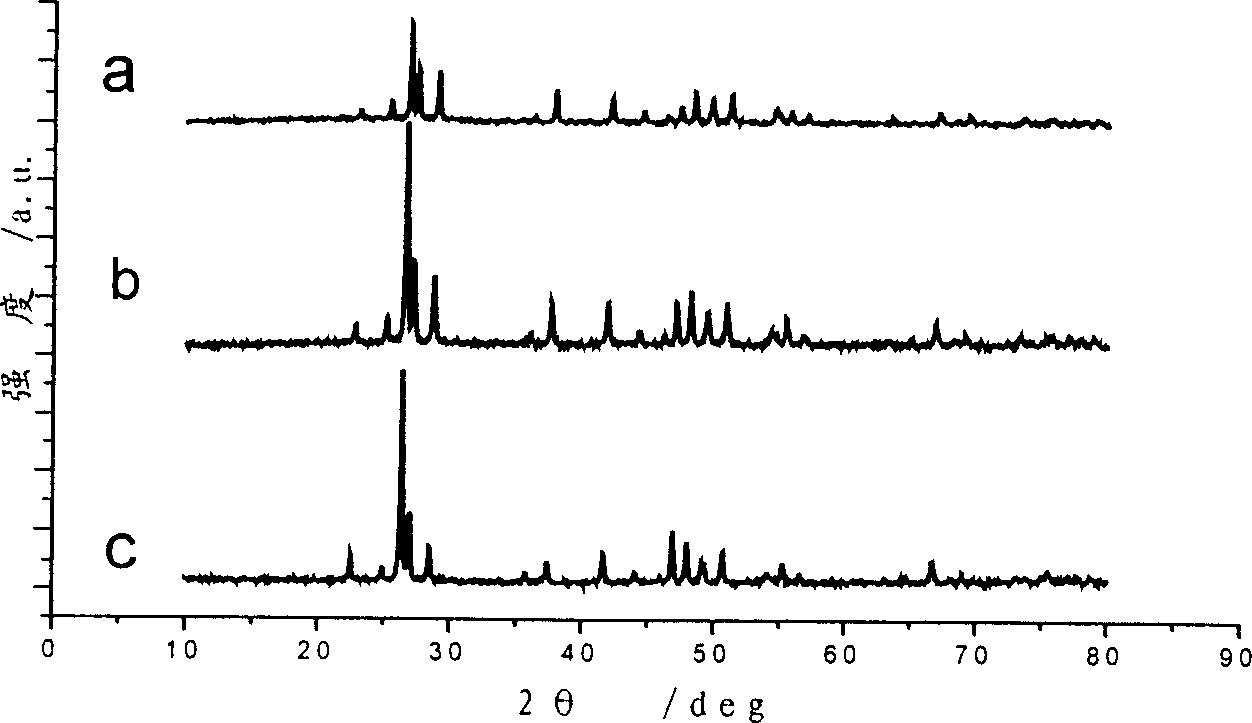

[0050] Example 1. α-PbF 2 Preparation of nanorods

[0051] Example 1-1 After successively adding 50ml cyclohexane, 10ml OP emulsifier (TRITONXT-10), 6ml n-pentanol, 10ml 0.1mol / L lead acetate aqueous solution to a 100mL round bottom flask, the system was placed in Ningbo, Zhejiang In the JY92-2D ultrasonic instrument (ultrasonic frequency 20kHz) produced by Zhike Institute of Devices, at room temperature and normal pressure, the power was set to 600W, and the quaternary emulsion was prepared by ultrasonication for 10 minutes. Then, 10ml of 0.2mol / L ammonium fluoride solution containing 0.5g PEG-6000 was added and allowed to stand for 24h. The product was separated by centrifugation, the precipitate was washed with distilled water and ethanol in sequence, and the resulting precipitate was vacuum-dried at room temperature to obtain a white powder, namely α-PbF 2 Nano stave. Powder XRD results show that it is pure orthorhombic α-PbF 2 . The positions and intensities of the p...

Embodiment 2

[0055] Example 2. α-PbF 2 Preparation of nanosheets

[0056] Example 2-1 After successively adding 50ml cyclohexane, 10ml OP emulsifier (TRITONXT-10), 6ml n-pentanol, 10ml 0.1mol / L lead acetate aqueous solution to a 100ml round bottom flask, the system was placed in a new In the JY92-2D ultrasonic instrument produced by Zhike Instrument Research Institute, at room temperature and normal pressure, the power was set to 600W, and the quaternary emulsion was prepared by ultrasonication for 10 minutes. Then, add 20 ml of 0.1 mol / L ammonium fluoride solution containing 1.0 g of PVP-K30, set the power to 400 W, continue ultrasonication for 5 min, and let stand for 1 h. The product was separated by centrifugation, the precipitate was washed with distilled water and ethanol in sequence, and the resulting precipitate was vacuum-dried at room temperature to obtain a white powder, namely α-PbF 2Nanosheets. Powder XRD results show that it is pure orthorhombic α-PbF2. The positions and ...

Embodiment 3

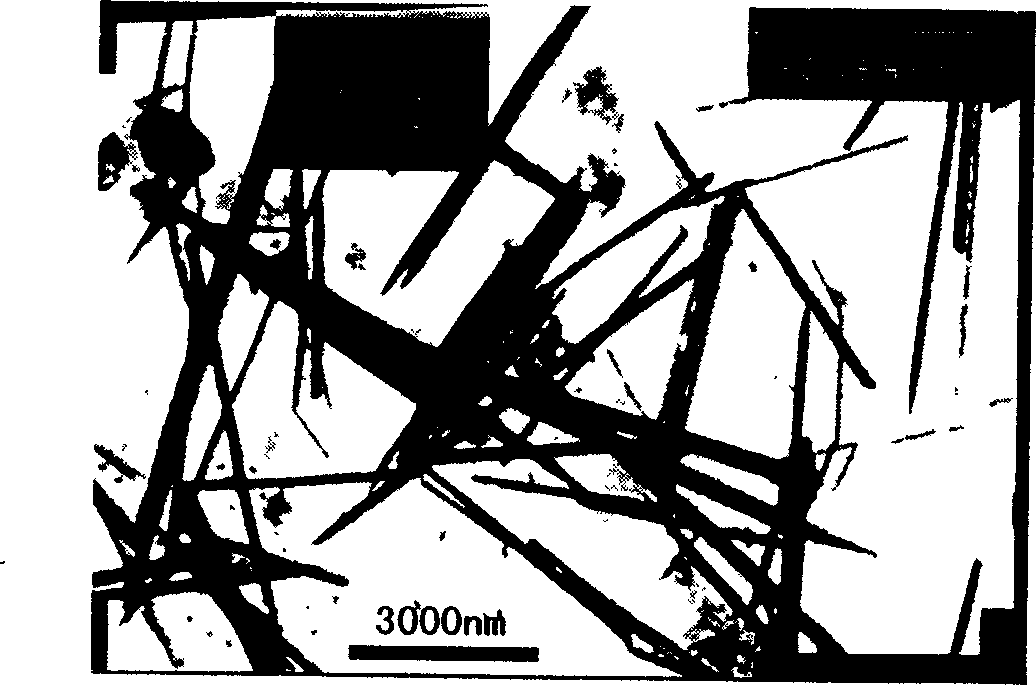

[0060] Example 3. α-PbF 2 Preparation of nanoribbons

[0061] Example 3-1 Add 50ml of cyclohexane, 7ml of OP emulsifier (TRITONXT-10), 4ml of n-pentanol, and 5ml of 0.5mol / L lead acetate aqueous solution to a 100ml round-bottomed flask, and place the system in Ningbo, Zhejiang Quaternary Emulsion A was prepared in JY92-2D Ultrasonic Apparatus produced by Zhike Institute, at room temperature and normal pressure, with the power set at 600W, and ultrasonication for 10 minutes.

[0062] Add 50ml of cyclohexane, 7ml of OP emulsifier (TRITON XT-10), 4ml of n-pentanol, and 5ml of 1.0mol / L ammonium fluoride aqueous solution into a 100ml round-bottomed flask, and place the system in Xinzhi, Ningbo, Zhejiang Quaternary Emulsion B was prepared in JY92-2D Ultrasonic Apparatus produced by Keqi Research Institute, at room temperature and pressure, with the power set at 600W, and ultrasonication for 10 minutes.

[0063] Put the prepared quaternary emulsion A and the prepared quaternary emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com