Method of processing sericin conteining natural silk fiber

A silk fiber and silk technology, which is applied in the chemical post-processing of fibers, fiber processing, textiles and papermaking, etc., can solve the problems of sodium metasilicate crystal dust, long production cycle, and poor product whiteness. The effect of industrial production, good product whiteness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

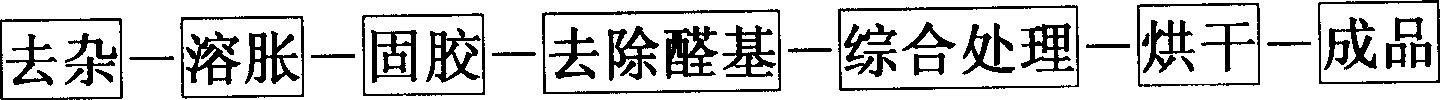

[0017] Embodiment 1: as figure 1 Shown, the method for processing silk fiber containing sericin, the main steps are as follows:

[0018] 1. Remove impurities: remove impurities such as grass stalks and leaves in silk;

[0019] 2. Swelling: Prepare a sulfuric acid solution with a PH value of 2 to 3, weigh 100 kg of silk and put it into 600 kg of the acid solution, put the two into the ultrasonic swelling pool, start the ultrasonic generator with a frequency of 28KHZ; swell for 0.5 hours After dehydration, the dehydration liquid flows back into the ultrasonic swelling tank and can be reused;

[0020] 3. Glue fixation: put the above-mentioned dehydrated silk into a mixture of sulfuric acid with a pH value of 1 and 6% formaldehyde solution, during which compressed air is introduced into the bottom of the pool, so that bubbles are continuously generated in the pool, and dehydrated after soaking for 3 hours ; The dehydration liquid flows back into the solid glue tank for reuse;

...

Embodiment 2

[0025] Embodiment 2: the method for processing silk fiber containing sericin, comprises the steps:

[0026] 1. Removal of impurities: remove impurities such as grass stalks and leaves in mulberry silk;

[0027] 2. Swelling: prepare sulfuric acid with a PH value of 3, weigh 100 kg of mulberry silk, add acid solution according to the ratio of silk weight 1:8, put the two into the ultrasonic swelling pool, start the ultrasonic generator with a frequency of 22KHZ; swell for 0.5 hours After dehydration, the dehydration liquid flows back into the ultrasonic swelling tank and can be reused;

[0028] 3. Glue fixing: Put the dehydrated silk into the mixed solution of sulfuric acid with a pH value of 1 and 5% glutaraldehyde solution, soak for 6 hours and then dehydrate, and the dehydration liquid flows back into the glue fixing pool for reuse;

[0029] 4. Removal of aldehyde groups: put the above-mentioned dehydrated silk into 12% hydrogen peroxide, and oxidize it for 5 hours, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com