Transmissive metal grating and preparation method thereof

A metal grating, transmissive technology, applied in diffraction grating, photosensitive material processing, microlithography exposure equipment, etc., can solve the problems of poor radiation resistance, poor corrosion resistance, poor impact resistance, etc. The effect of low cost and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

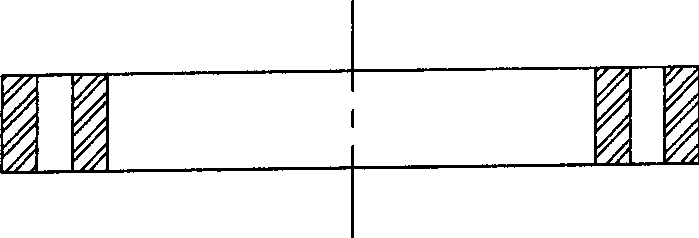

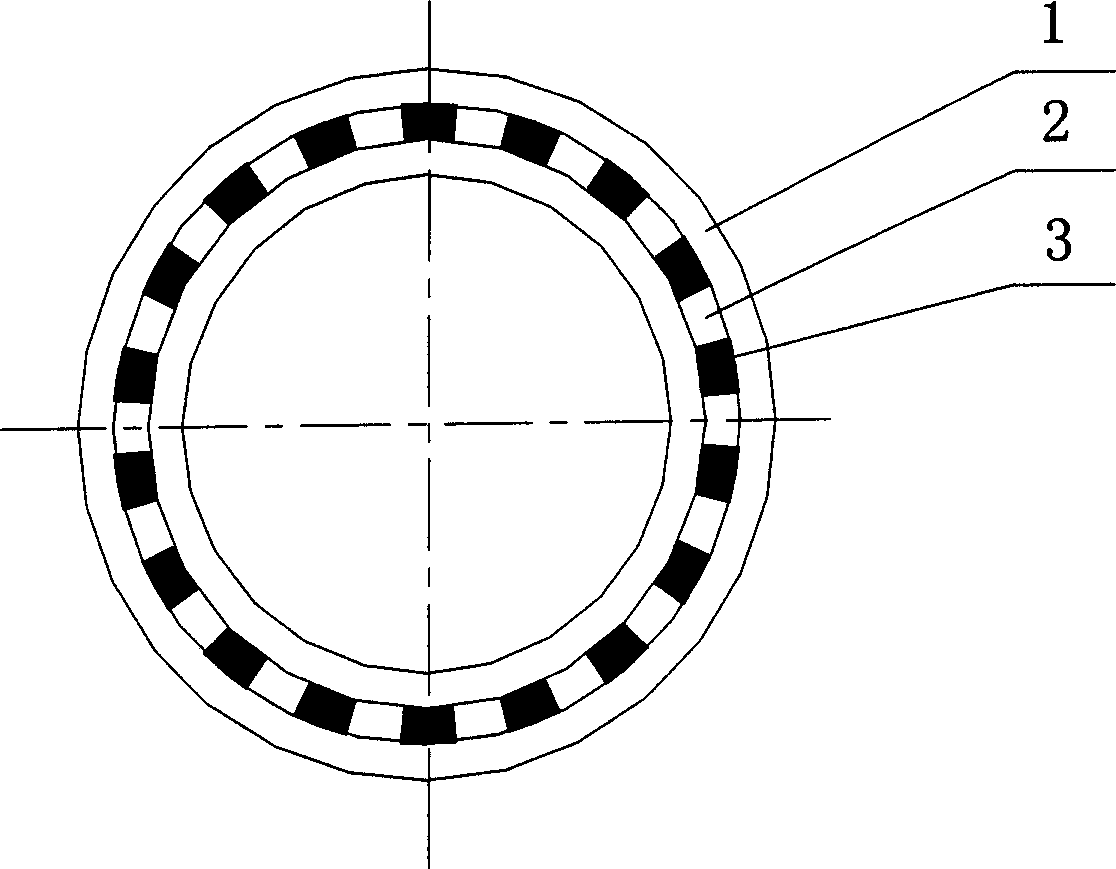

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a metal substrate 1, a grating light stripe 2 and a dark stripe 3 on the upper and lower surfaces of the metal substrate 1. The grating light stripe 2 is a gap on the metal substrate 1 with a light transmittance of 100%, and the dark stripe 3 is a metal The substrate 1 itself has a light transmittance of 0%, and the metal substrate 1 is a thin sheet or thin ruler of stainless steel, copper, or aluminum.

[0016] The manufacturing method of the present invention will be described in detail below taking stainless steel sheet as an example:

[0017] ① After selecting a stainless steel sheet of appropriate size and thickness and leveling it, use dilute nitric acid with a concentration of 9-11% to remove oxides on the surface of the stainless steel sheet, and use 10-20% concentrated lye to remove oil stains on the surface of the stainless steel sheet;

[0018] ②Use HNO 3 Solution for deep treatment of stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com