Process for treating waste water of methylene blue dye and process for preparing catalyst

A methylene blue dye and wastewater treatment technology, applied in the field of water treatment, can solve the problems of difficult mass production, harsh experimental conditions, and poor repeatability, and achieve the effects of rapid response, simple preparation, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

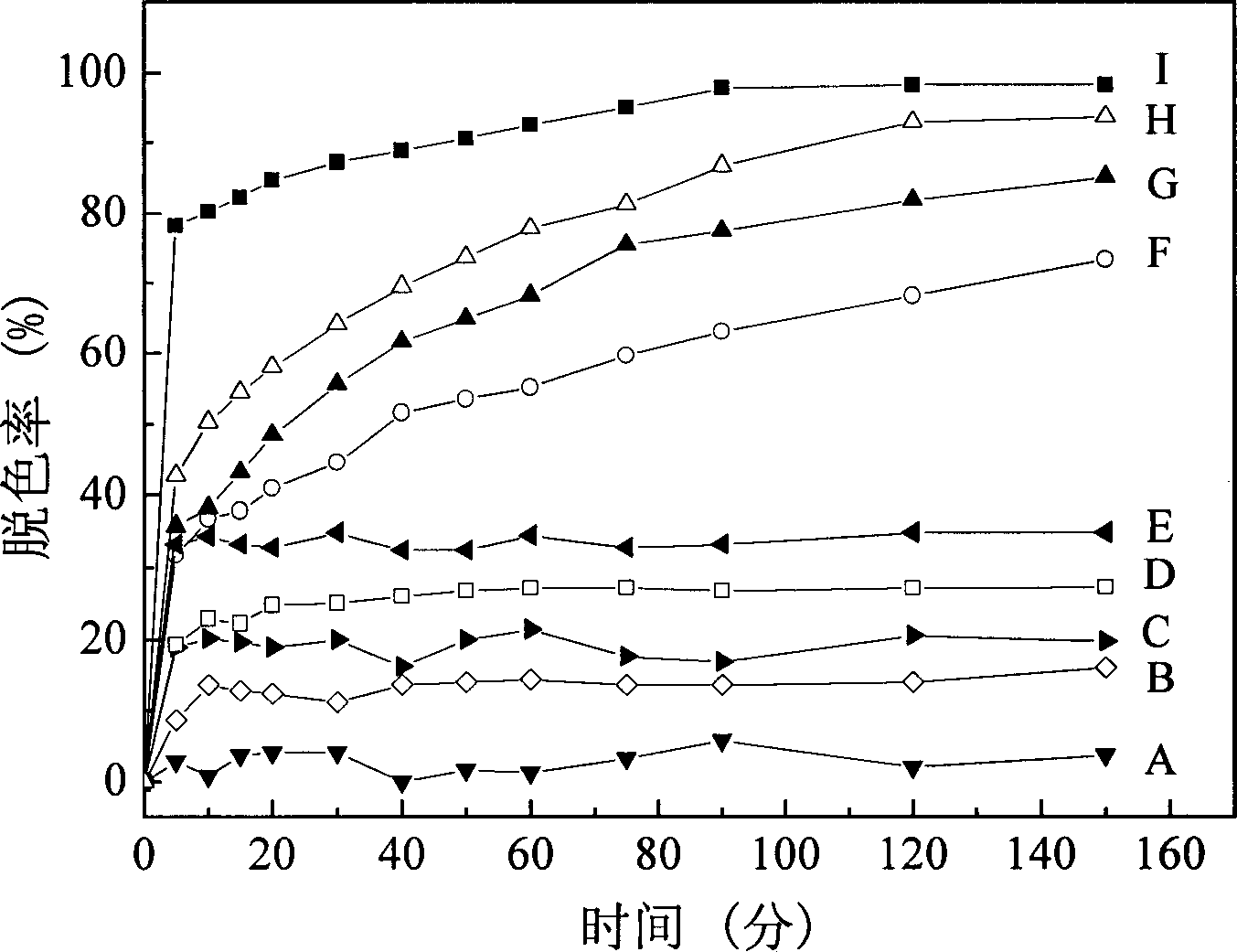

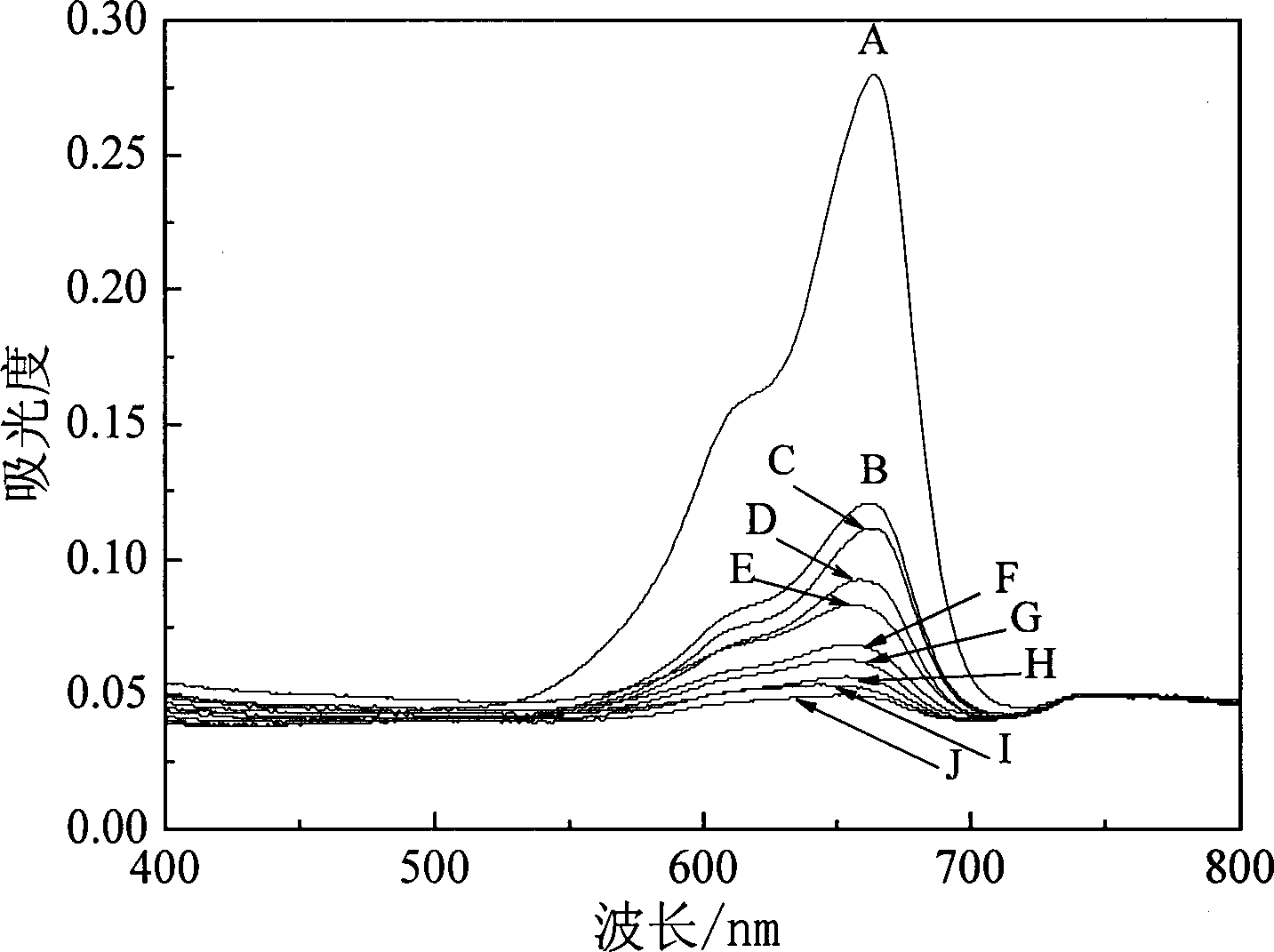

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of γ-MnOOH nanorods

[0043] After mixing 4g of potassium permanganate, 400mL of distilled water and 4mL of absolute ethanol evenly, react at 150°C and 0.5-1.0Mpa for 24 hours. Then the product was taken out, washed 3-5 times with distilled water, and then washed once with absolute ethanol. Vacuum-dried at 70° C. for 4 hours to obtain a brown-yellow powder.

[0044] Analysis by X-ray powder diffraction (XRD) and transmission electron microscope (TEM) shows that the obtained product is a monoclinic γ-MnOOH nanorod with a diameter of 30-500 nm and a length of several micrometers to tens of micrometers.

Embodiment 2

[0045] Example 2: β-MnO 2 Preparation of nanorods

[0046] The γ-MnOOH nanorods were calcined at 250 °C in air for 8 hours to obtain a black product.

[0047] X-ray powder diffraction (XRD) and transmission electron microscope (TEM) analysis showed that the obtained product was tetragonal β-MnO 2 The nanorods have a diameter between 40-300nm and a length of several micrometers to more than ten micrometers.

Embodiment 3

[0048] Example 3: Mn 2 o 3 Preparation of nanorods

[0049] The γ-MnOOH nanorods were calcined at 700 °C in air for 8 hours to obtain a black product.

[0050] Analysis by X-ray powder diffraction (XRD) and transmission electron microscope (TEM) showed that the obtained product was orthorhombic Mn 2 o 3 Nanorods have a diameter between 50-300nm and a length of several microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com