Method of producing photon scanning tunneling microscope probe with optical fiber and Indium-Tin-oxide

A technology of indium tin oxide and scanning tunneling, which is applied in the direction of scanning probe technology, scanning probe microscopy, and manufacturing microstructure devices, etc., can solve the problems of inability to use electron transmission, photon and detection photon functional characteristics reduction, etc., Achieve the effect of excellent electrical conductivity and light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

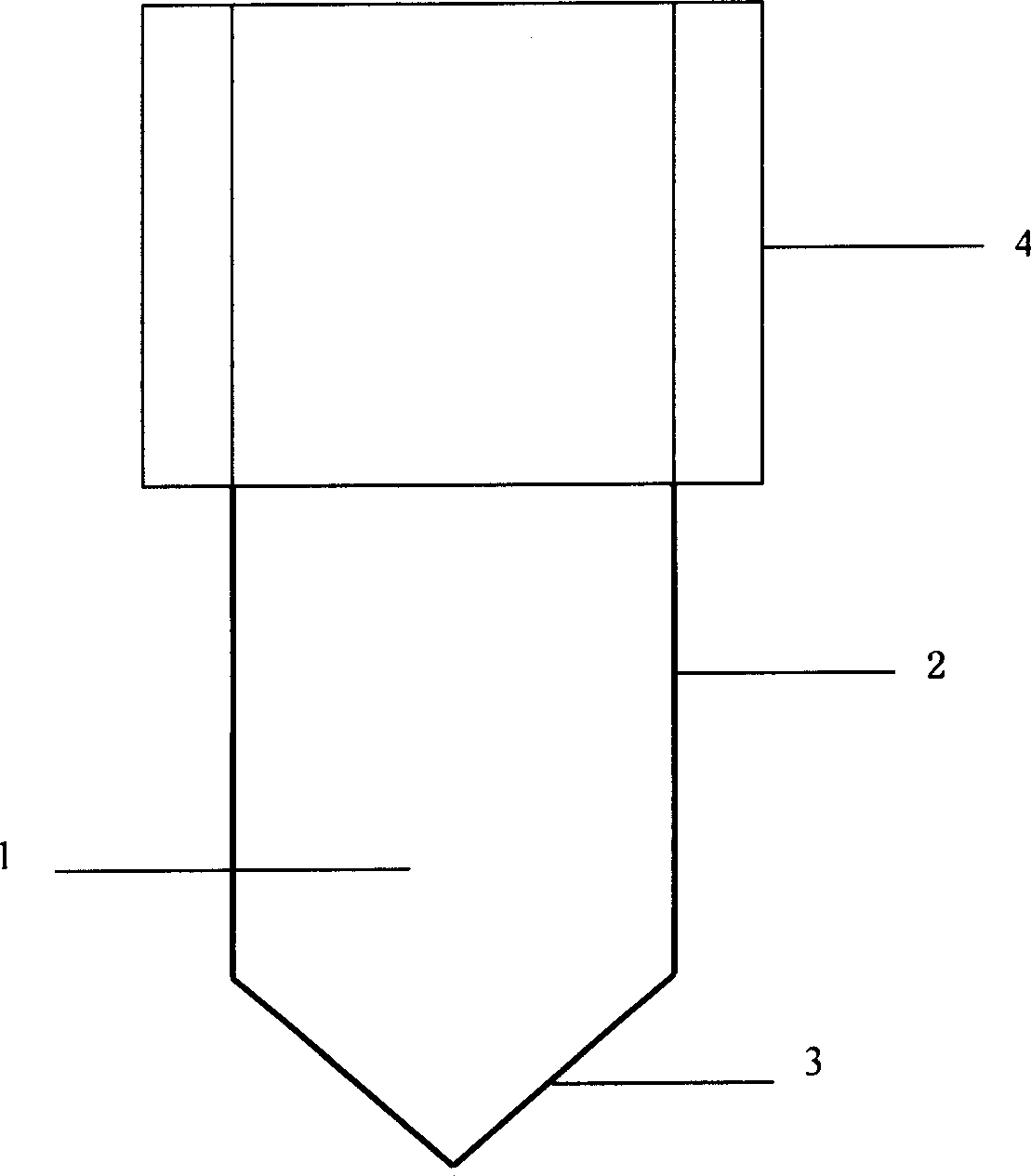

Image

Examples

Embodiment 1

[0027] A method for making photon scanning tunneling microscope probe with optical fiber and indium tin oxide, is characterized in that comprising the steps:

[0028] (1) Pretreatment of optical fiber: remove the optical fiber coating, cut it into small sections with a length of 1.0-2.0cm, and clean it;

[0029] (2) Preparation of buffer solution: with NH 4 F, HF and H 2 O is an etchant, prepared as a buffer solution; the buffer solution consists of NH 4 F, HF, H 2 O is obtained by preparing 10 grams, 20 grams and 100 grams respectively;

[0030] (3) Optical fiber chemical etching: immerse 0.1-0.3 mm of one end of the optical fiber obtained in step (1) in the buffer solution prepared in step (2), take out the needle tip immediately after etching is completed, and clean it with deionized water to obtain the tip A needle tip with a radius of curvature of about 40nm;

[0031] (4) Evaporation deposition of metal conductive film: the optical fiber obtained in step (3) is place...

Embodiment 2

[0039] A method for making photon scanning tunneling microscope probe with optical fiber and indium tin oxide, is characterized in that comprising the steps:

[0040] (1) Pretreatment of optical fiber: remove the optical fiber coating, cut it into small sections with a length of 1.0-2.0cm, and clean it;

[0041] (2) Preparation of buffer solution: with NH 4 F, HF and H 2 O is an etchant, prepared as a buffer solution; the buffer solution consists of NH 4 F, HF, H 2 O is obtained by preparing 10 grams, 30 grams and 100 grams respectively;

[0042] (3) Optical fiber chemical etching: immerse 0.1-0.3 mm of one end of the optical fiber obtained in step (1) in the buffer solution prepared in step (2), take out the needle tip immediately after etching is completed, and clean it with deionized water to obtain the tip A tip with a radius of curvature of about 60nm;

[0043] (4) Evaporation deposition of metal conductive film: the optical fiber obtained in step (3) is placed in th...

Embodiment 3

[0050] A method for making photon scanning tunneling microscope probe with optical fiber and indium tin oxide, is characterized in that comprising the steps:

[0051] (1) Pretreatment of optical fiber: remove the optical fiber coating, cut it into small sections with a length of 1.0-2.0cm, and clean it;

[0052] (2) Preparation of buffer solution: with NH 4 F, HF and H 2 O is an etchant, prepared as a buffer solution; the buffer solution consists of NH 4 F, HF, H 2 O is obtained by preparing 10 grams, 25 grams and 100 grams respectively;

[0053] (3) Optical fiber chemical etching: immerse 0.1-0.3 mm of one end of the optical fiber obtained in step (1) in the buffer solution prepared in step (2), take out the needle tip immediately after etching is completed, and clean it with deionized water to obtain the tip A tip with a radius of curvature of about 50nm;

[0054] (4) Evaporation deposition of metal conductive film: the optical fiber obtained in step (3) is placed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com