Water gel fast forming process based on bionic process

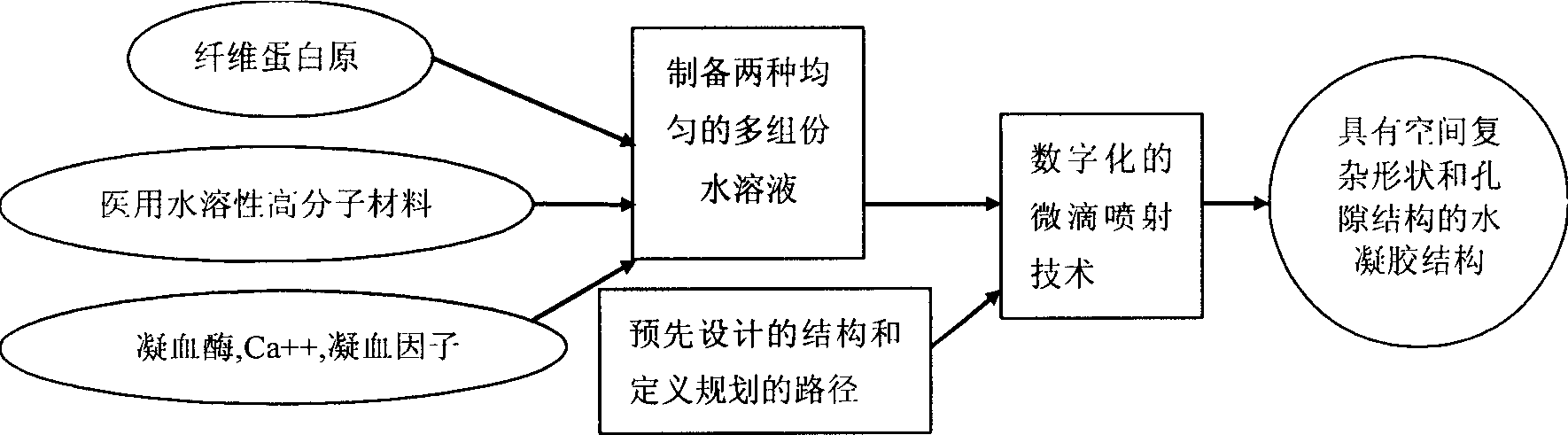

A forming process, hydrogel technology, applied in biomanufacturing and bionic manufacturing, tissue engineering material manufacturing and rapid prototyping, manufacturing science and other interdisciplinary fields, can solve the problem of difficult operation of hydrogel materials, achieve structural stability, Excellent biocompatibility and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Fibrin-gelatin three-dimensional structure produced by this process. The mixture of fibrinogen and gelatin is prepared into component I aqueous solution, the concentration is 0.050g / ml, wherein the mass ratio of fibrinogen and gelatin is 2: 3, then make certain calcium chloride, thrombin solution as component II, the concentration of thrombin is 5000U / ml, the concentration of calcium chloride is 0.05g / ml, and it is sterilized for use; the material is pre-cooled at low temperature first, and in an environment of 4°C, according to the pre-designed structure and defined planning path, By means of extrusion, component I is sprayed into the aseptic forming chamber of component II filled with atomization; after spraying to the designated position, component 1 undergoes a sol-gel transition to form a hydrogel; layer by layer accumulation is obtained Three-dimensional structure of fibrinogen gelatin.

Embodiment 2

[0028] Example 2: The fibrin-gelatin three-dimensional structure produced by this process. The mixture of fibrinogen and gelatin is prepared as component I aqueous solution, the concentration is 0.200g / ml, wherein the mass ratio of fibrinogen and gelatin is 1:3, and then a certain amount of thrombin and coagulation factor solution is used as component II , the concentration of thrombin is 2U / ml, the concentration of coagulation factor is 32U / ml, and it is sterilized for later use; the material is pre-cooled at low temperature, and in an environment of 4°C, according to the pre-designed structure and defined path, it is extruded The method, the component I is sprayed into the liquid component II environment; after spraying to the designated position, the component I undergoes a sol-gel transition to form a hydrogel; the fibrinogen-gelatin three-dimensional structure is obtained layer by layer.

Embodiment 3

[0029] Example 3: The three-dimensional structure of fibrin-agarose produced by this process. The mixture of fibrinogen and agarose is dissolved in calcium chloride solution to prepare component I aqueous solution, the concentration is 0.050g / ml, and it is sterilized for later use, wherein the mass ratio of fibrinogen and agarose is 3: 2, and then Thrombin and coagulation factors are embedded and fixed on the inner surface of the nozzle cavity; at 37°C, according to the pre-designed structure and defined path, component I is immobilized when it is sprayed through the nozzle by extrusion. The sol-gel transformation occurs to form a hydrogel through the action of the enzyme, and then the three-dimensional structure of fibrinogen-agarose is obtained through layer-by-layer accumulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com