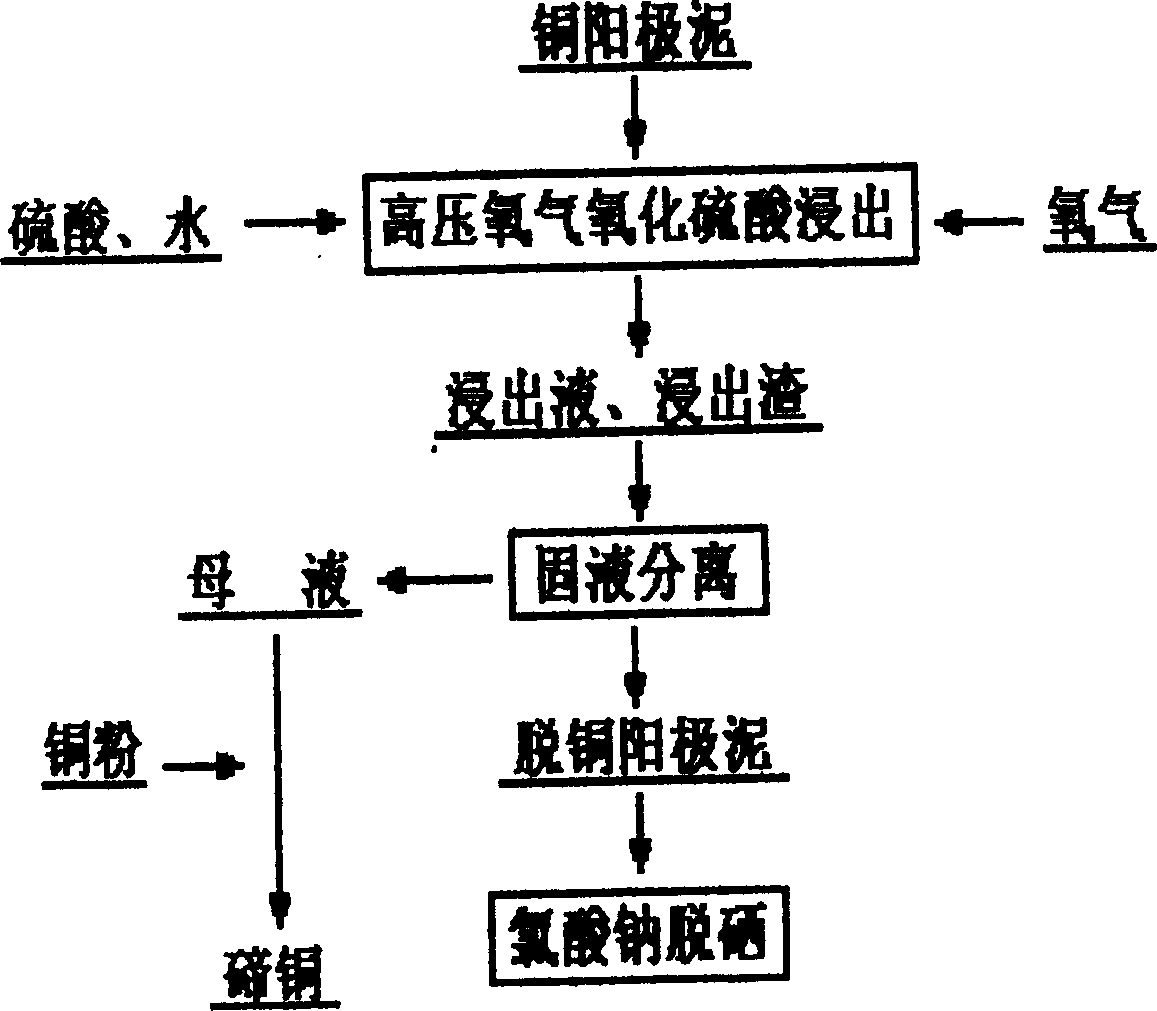

Method for leaching tellurium from copper anode mud using pressurized acid leaching process

A copper anode slime and acid leaching technology, applied in the direction of improving process efficiency, element selenium/tellurium, etc., can solve the problems of poor working conditions, large loss of tellurium, low cost, etc. The effect of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Copper anode slime contains 1.14% tellurium and 1% moisture.

[0031] Slurry the copper anode mud containing 1.14% tellurium and 1% moisture, and sieve out large grains of sand.

[0032] Slurry the sieved copper anode slime with sulfuric acid solution containing 70g / l of acid, add it into a titanium acid-resistant autoclave with a volume of 5L, and continuously feed compressed air to maintain the pressure in the autoclave at 0.5MPa and the temperature at 100°C. Pressure leaching, leaching time 60 minutes.

[0033] The tellurium leaching rate is 40.1%, the slag rate is 60.32%, and the leaching slag contains 1.10% tellurium.

Embodiment 2

[0034] Example 2: Copper anode slime contains 1.23% tellurium and 12% moisture.

[0035] Slurry the copper anode mud containing 1.23% tellurium and 12% moisture, and sieve out large grains of sand.

[0036] The sieved copper anode slime is slurried with sulfuric acid solution containing 100g / l of acid, and added to a titanium acid-resistant autoclave with a volume of 5L, and 33% oxygen-enriched air is continuously introduced to maintain the pressure in the autoclave at 0.7MPa. 120°C, pressurized leaching, leaching time 90 minutes.

[0037] The tellurium leaching rate is 41.3%, the slag rate is 55.46%, and the leaching slag contains 1.12% tellurium.

Embodiment 3

[0038] Embodiment 3: Copper anode slime contains 0.99% tellurium and 1% moisture.

[0039] Slurry the copper anode mud containing 0.99% tellurium and 1% water, and sieve out large grains of sand.

[0040] Mix the sieved copper anode slime with sulfuric acid solution containing 200g / l of acid, put it into a titanium acid-resistant autoclave with a volume of 5L, and continuously feed 99.5% industrial oxygen to maintain the pressure in the kettle at 1.6Mpa and the temperature at 180°C , carry out pressure leaching, leaching time 120 minutes.

[0041] The tellurium leaching rate is 45.3%, the slag rate is 53.46%, and the leaching slag contains 0.81% copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com