Polymer for forming anti-reflective coating layer

An anti-reflection coating and polymer technology, which can be used in photosensitive materials used in optomechanical equipment, building structures, and photoplate-making processes on patterned surfaces, and can solve problems such as unsatisfactory light absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

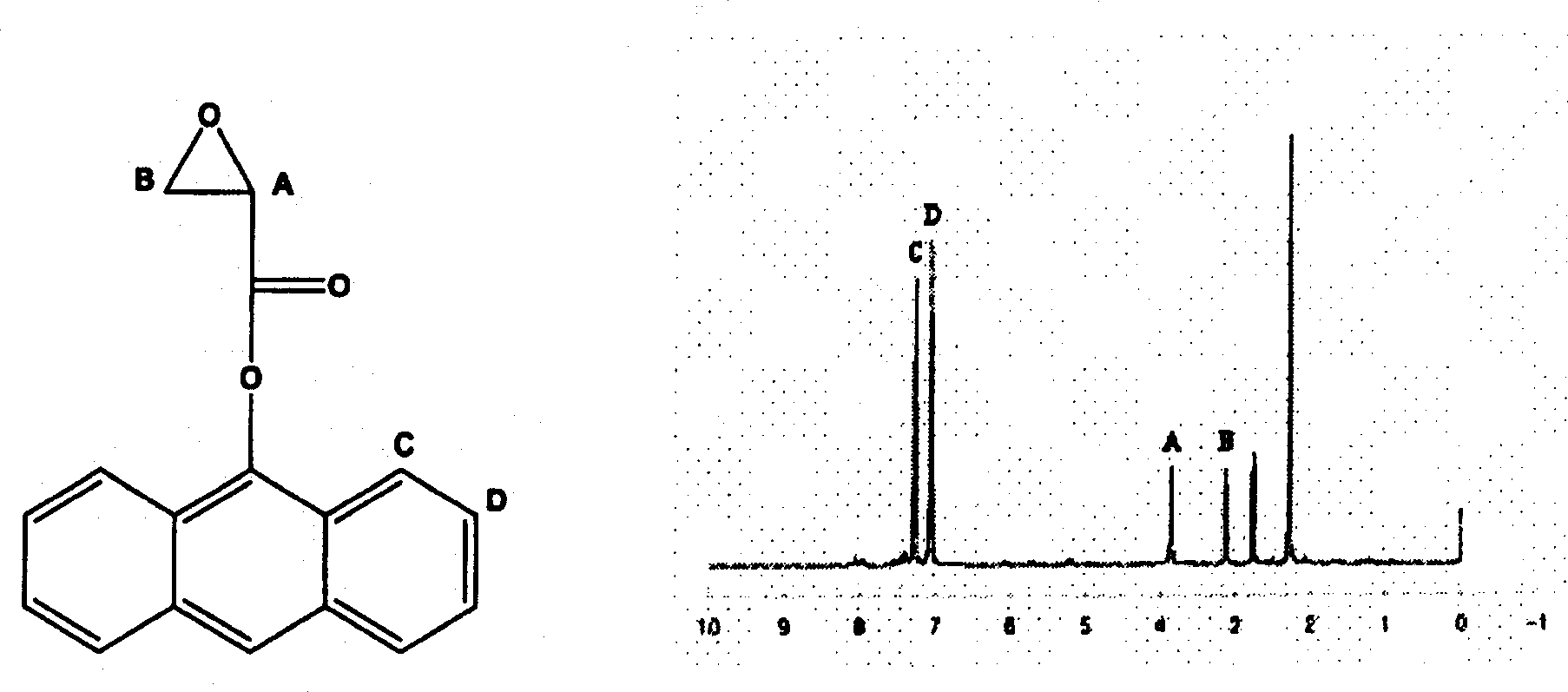

[0055] [Preparation Example 1] Preparation of anthracene acrylate oxide

[0056] As shown in Reaction 1 below, 30 g of 9-anthracene acrylate and 1 L of chloroform were added to a 2 L reactor, and stirred and cooled in ice water. 47 g of 3-chloroperoxybenzoic acid (mCPBA) was slowly added to the cooled solution, and reacted at room temperature for 24 hours. After completion of the reaction, 3-chlorobenzoic acid (by-product) was removed by filtering the resulting product, followed by washing twice with a saturated aqueous solution of sodium sulfite, once with a saturated aqueous solution of sodium bicarbonate, and once with a saturated aqueous solution of sodium chloride. times and washed once with distilled water to remove residual 3-chlorobenzoic acid. Then, the product was dried with magnesium sulfate, and chloroform was removed under reduced pressure, and then the product was vacuum-dried for 1 day to obtain 25.5 g of pure anthracene acrylate oxide. exist figure 1 The NMR...

preparation Embodiment 22

[0059] [Preparation Example 2] Preparation of 2-hydroxyethyl-oxycarbonyl oxirane

[0060] As shown in Reaction Formula 2 below, except that 30 g of 9-anthracene acrylate was replaced with 30 g of 2-hydroxyethyl-acrylate (HEA), the reaction described in Preparation Example 1 was carried out to obtain 25 g of 2-hydroxyethyl-acrylate Base-oxycarbonyloxirane.

[0061] [Reaction 2]

[0062]

preparation Embodiment 3

[0063] [Preparation Example 3] Preparation of glycidyl-oxycarbonyl oxirane

[0064] As shown in Reaction Formula 3 below, except that 30 g of 9-anthracene acrylate was replaced with 30 g of glycidyl acrylate, the reaction described in Preparation Example 1 was carried out to obtain 22 g of glycidyl-oxycarbonyl oxirane .

[0065] [reaction formula 3]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com