Rare earth nanometer titanium film electrothermal tube

A technology of nano-titanium and electric heating tubes, which is applied in the direction of heating element materials, heating element shapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

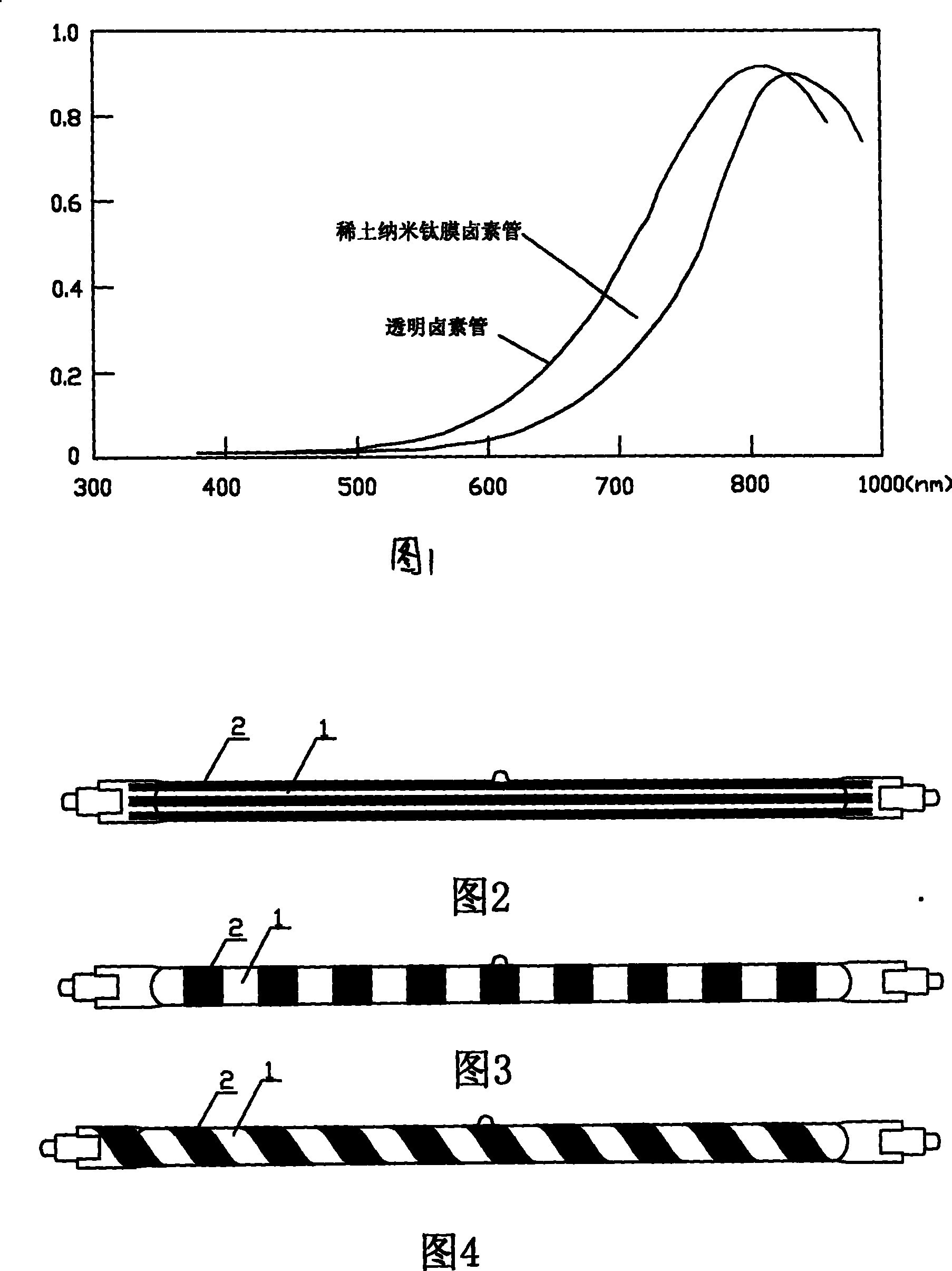

[0028] The rare-earth nano-titanium film electric heating tube of the present invention is compounded with a rare-earth nano-titanium film 2 on the surface of the electric heating tube 1, and the composition of the film is prepared from a powder mixture of 25% to 30% and an adhesive solution of 65% to 75%. The agent adopts a water-soluble resin solution such as melamine formaldehyde resin solution, wherein the content of the powder mixture includes 29.2% of rare earth elements, 30% of high-temperature pigments, and titanium dioxide includes ordinary titanium dioxide and nano-titanium dioxide, ordinary titanium dioxide is 10%, and nano-titanium dioxide is 0.8%. 30% frit, ground to more than 900 mesh; after stirring the above powder mixture and binder solution evenly, through high-temperature physical vapor deposition process, composite on the surface of the heating tube to form a composite film 2, the thickness of the composite film is 5-25 μm, It is formed by drying at 100°C to...

Embodiment 2

[0031] In the above formula, the composition of the film is prepared from 30% of powder mixture and 70% of binder solution. In the powder mixture of the composition of the film, 6% of high-temperature pigment, 32% of ordinary titanium dioxide, and 32% of nano-titanium dioxide 2%, rare earth elements 30%, frit 30%.

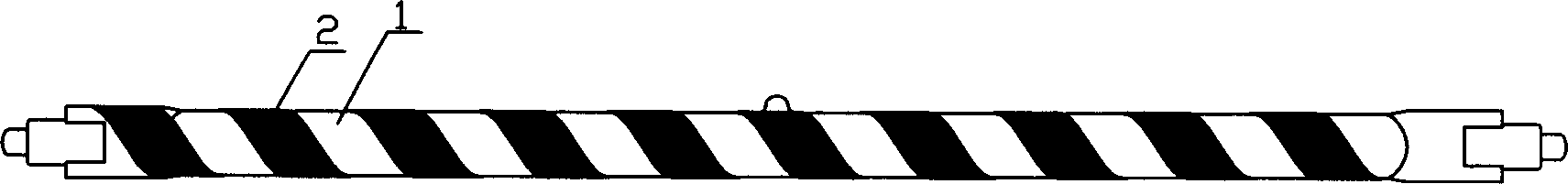

[0032] As shown in Figure 2-Figure 4, the rare earth nano-titanium film is composited on the surface of the tube in intervals, forming various intervals such as horizontal intervals, oblique intervals, and longitudinal intervals.

[0033] In the above embodiment, traces of zirconium oxide, zinc oxide, boron oxide, and silicon oxide can also be added to the powder mixture, the content of which is less than 1%, which reduces the amount of high-temperature pigments or ordinary titanium dioxide or rare earth element-containing substances accordingly. The proportion of the content can be.

[0034] The electric heating tube of the present invention can be used for halog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com