Template copolymerizing synthetic process of semi-intercrossing network reversible pH sensitive aquagel

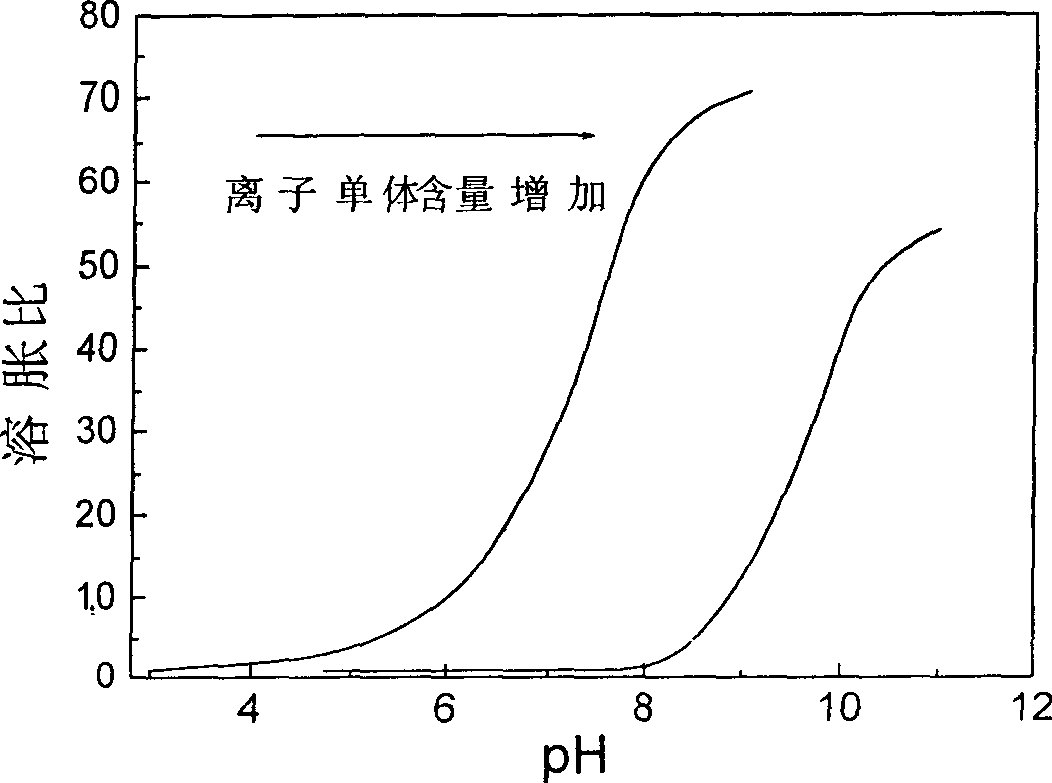

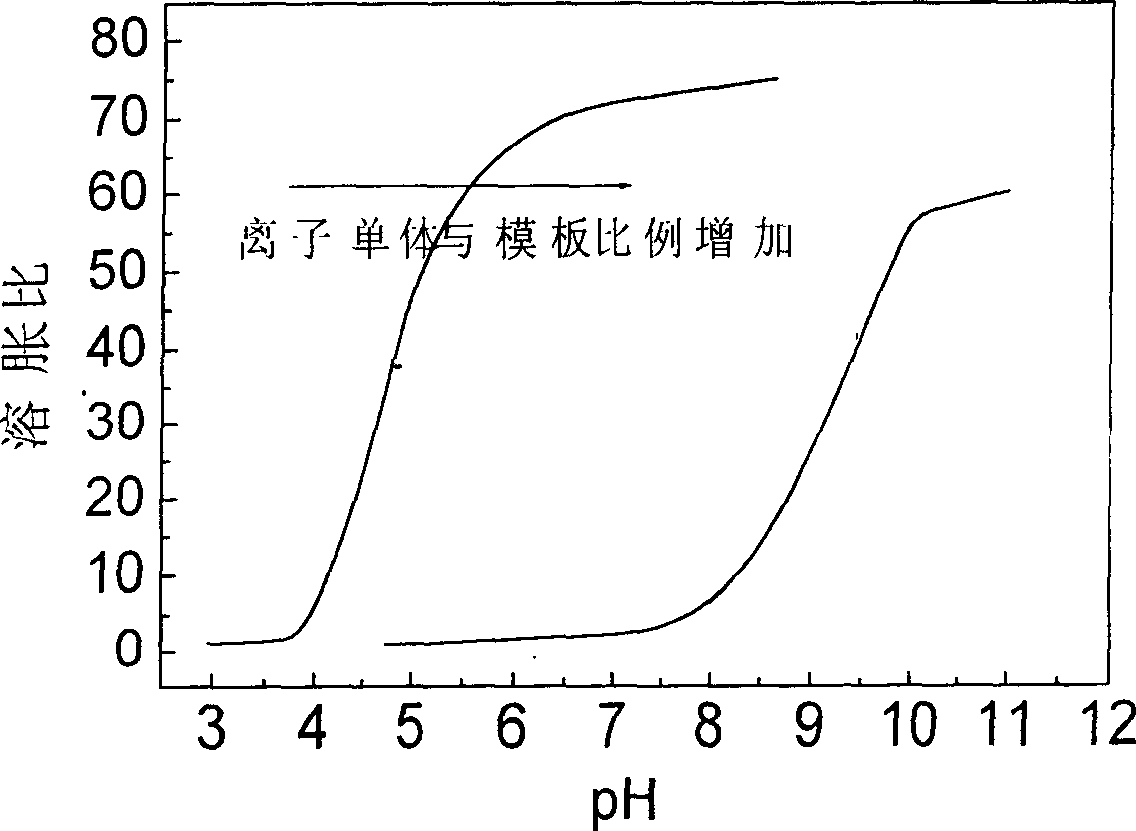

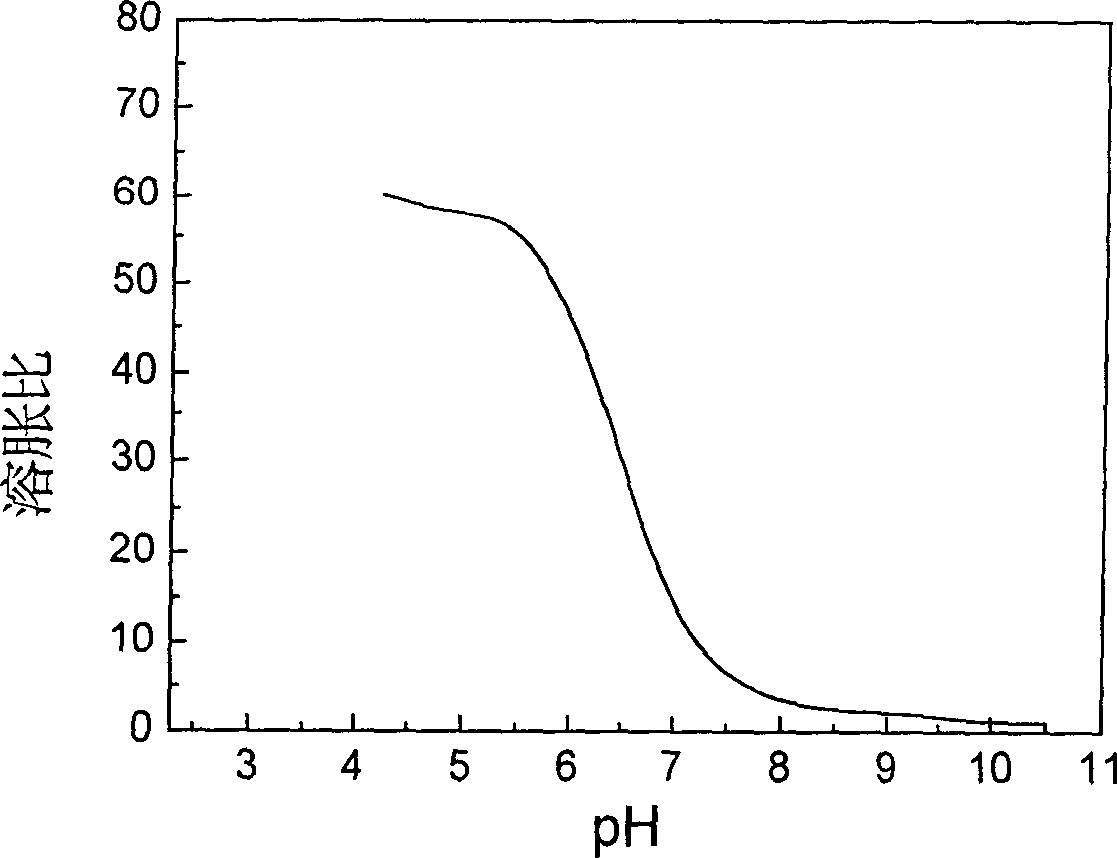

A technology of semi-interpenetrating network and synthesis method is applied in the field of template copolymerization method to synthesize semi-interpenetrating network reversible pH-sensitive hydrogel, which can solve the problems of poor mechanical properties and recoverability, affecting gel swelling/shrinking properties, etc. Achieve the effect of rapid volume expansion or contraction, high recovery rate and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of acrylamide / acrylic acid / polyallylammonium chloride semi-interpenetrating network reversible pH-sensitive hydrogel copolymers.

[0033] In the reactor, add 35.5g (0.50mol) acrylamide, 15.43g (0.21mol) acrylic acid, 2.01g (0.021mol) polyallyl ammonium chloride, 0.11gN, N'-methylenebisacrylamide, 41ml Deionized water, adjust the pH with sodium carbonate to be 5.5, feed high-purity nitrogen into the reactor for 30 minutes, add initiator azobisisobutylamidine hydrochloride 0.035g (0.07wt% monomer weight), continue to feed nitrogen for 10 minutes Minutes, react at 65°C for 15 hours to obtain a white cross-linked polymer gel, cut the gel into small pieces about 1 cm in size, soak in deionized water, change the water every 8 hours, and continue soaking for 48 hour, filter off the water, add acetone to dehydrate the gel, and then vacuum-dry at 50°C to constant weight to obtain a xerogel. The molar ratio of acrylic acid to acrylamide in this gel is 0.43 / 1, and acryli...

Embodiment 2

[0035] Synthesis of acrylamide / acrylic acid / polyallylammonium chloride semi-interpenetrating network reversible pH-sensitive hydrogel copolymers.

[0036] In the reactor, add 0.2g (0.0028mol) acrylamide, 1.8g (0.025mol) acrylic acid, 4.66g (0.05mol) polyallyl ammonium chloride, 0.428g N, N'-methylenebisacrylamide, 95ml of deionized water, adjust the pH to 10 with potassium hydroxide, add 0.1g of initiator ammonium persulfate, and react at 40°C for 15 hours. The post-treatment process was the same as in Example 1 to obtain a xerogel, in which the molar ratio of acrylic acid to acrylamide was 8.93 / 1, and the molar ratio of acrylic acid to template polyallyl ammonium chloride was 1 / 2.

Embodiment 3

[0038] Synthesis of acrylamide / acrylic acid / polyallylammonium chloride semi-interpenetrating network reversible pH-sensitive hydrogel copolymers.

[0039] In the reactor, add 6.0g (0.085mol) acrylamide, 4.0g (0.056mol) acrylic acid, 5.24g (0.056mol) polyallyl ammonium chloride, 0.22g N, N'-methylene bisacrylamide, 85ml of deionized water, adjusted to pH 6.5 with potassium carbonate. Add 0.1 g of initiator azobisisobutylamidine hydrochloride, and react at 60° C. for 15 hours. The post-treatment process was the same as in Example 1 to obtain a xerogel, in which the molar ratio of acrylic acid to acrylamide was 0.66 / 1, and the molar ratio of acrylic acid to template polyallyl ammonium chloride was 1 / 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com