Solubilization carrier for drug, its preparation method and application

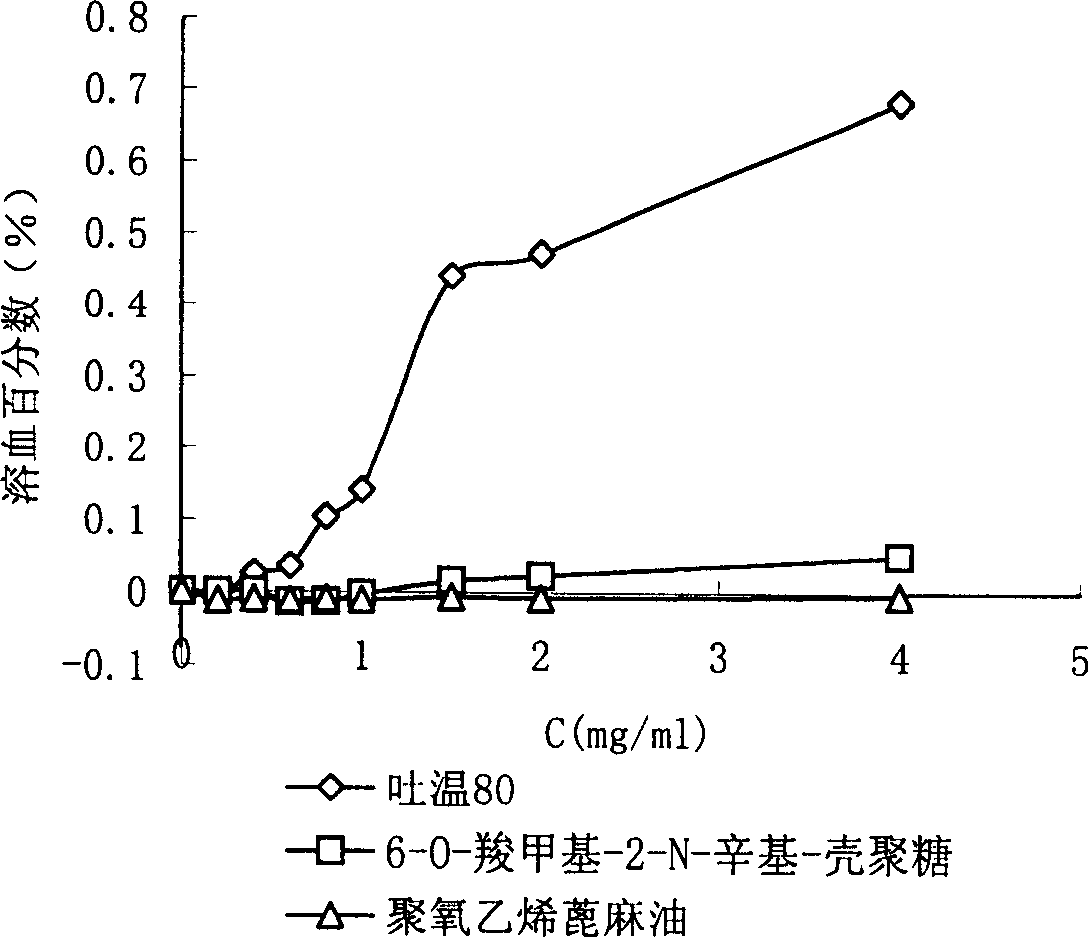

A drug and carrier technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, freeze-dried delivery, etc., can solve problems such as hemolysis, turbidity, dilution instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Preparation of 6-O-carboxymethyl-2-N-octyl chitosan (connecting hydrophilic group first and then hydrophobic group)

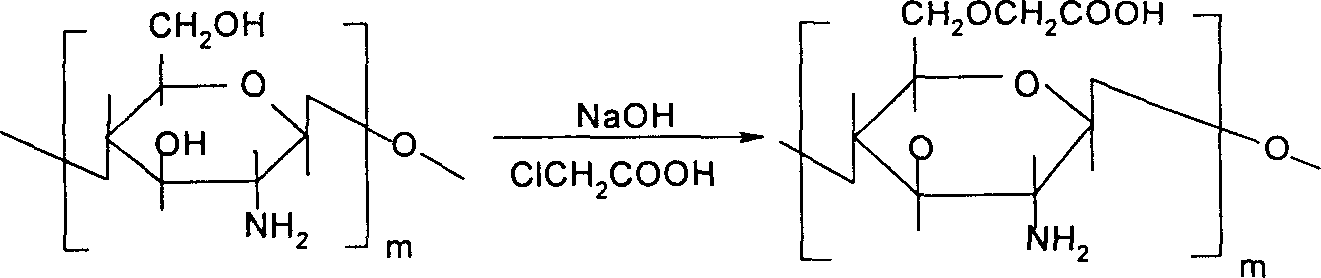

[0121] 1. Preparation of 6-O-carboxymethyl chitosan

[0122] Suspend 1g of chitosan in isopropanol, add 5g of NaOH, stir at 30°C for 12h, add 6g of chloroacetic acid in isopropanol, react at 35°C for 5h, pour off the supernatant, add a certain amount of water, and use Adjust the pH to 7 with NaOH aqueous solution, precipitate with methanol, filter, wash with 90% ethanol and dry in vacuum to obtain highly substituted 6-O-carboxymethyl chitosan as light yellow or white powder.

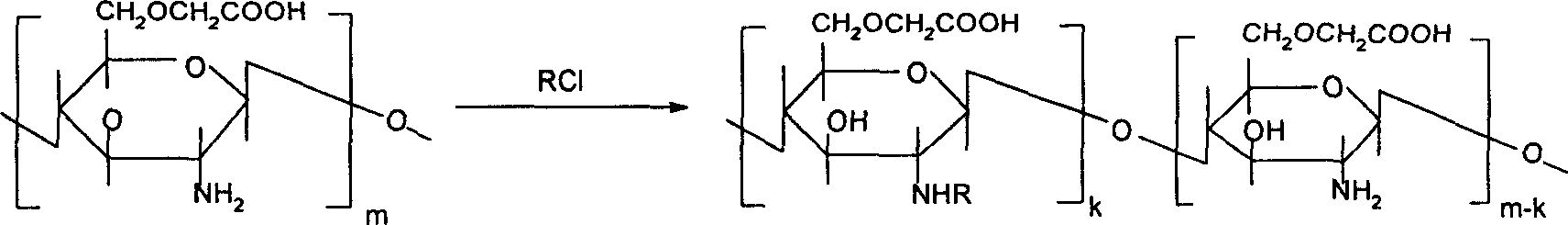

[0123] 2. Preparation of 6-O-carboxymethyl-2-N-octyl chitosan

[0124] A reacts with haloalkane

[0125] Disperse 1g of 6-O-carboxymethyl chitosan evenly in isopropanol, add 2g of NaOH, alkalinize at 35°C, add n-octyl chloride under stirring, react at 30°C for 8h, adjust pH to 7, add acetone to precipitate, filter, filter The cake was washed with ether, and the sample was vacuum...

Embodiment 2

[0131] Preparation of 6-O-carboxymethyl-2-N-octyl chitosan (first connect hydrophobic group and then connect hydrophilic group)

[0132] 1. Preparation of 2-N-octyl chitosan

[0133] The method is the same as in Example 1, 2, replacing 6-O-carboxymethyl chitosan with chitosan.

[0134] 2. Preparation of 6-O-carboxymethyl-2-N-octyl chitosan

[0135] Method is with embodiment 1 middle 1, replaces chitosan with 2-N-octyl chitosan

[0136] Elemental analysis showed that the deacetylation degree was 91.5%, the carboxymethyl substitution degree was 95%, and the octyl substitution degree was 48%.

Embodiment 3

[0138] Preparation of 6-O-carboxymethyl-2-N-decyl chitosan

[0139] Replace n-octyl chloride and n-octyl aldehyde in embodiments 1 and 2 with n-decyl chloride and n-decyl aldehyde, and the preparation method is the same as in embodiments 1 and 2.

[0140] Elemental analysis showed that the deacetylation degree was 91.5%, the carboxymethyl substitution degree was 98%, and the decyl substitution degree was 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com