Cu-W thin film coating integrated composite heat sink

A film and coating technology, applied in cooling/ventilation/heating transformation, lasers, electrical components, etc., can solve the problems of large thermal stress, poor thermal conductivity, reduce the reliability and life of high-power semiconductor lasers, etc., to improve the life. , the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

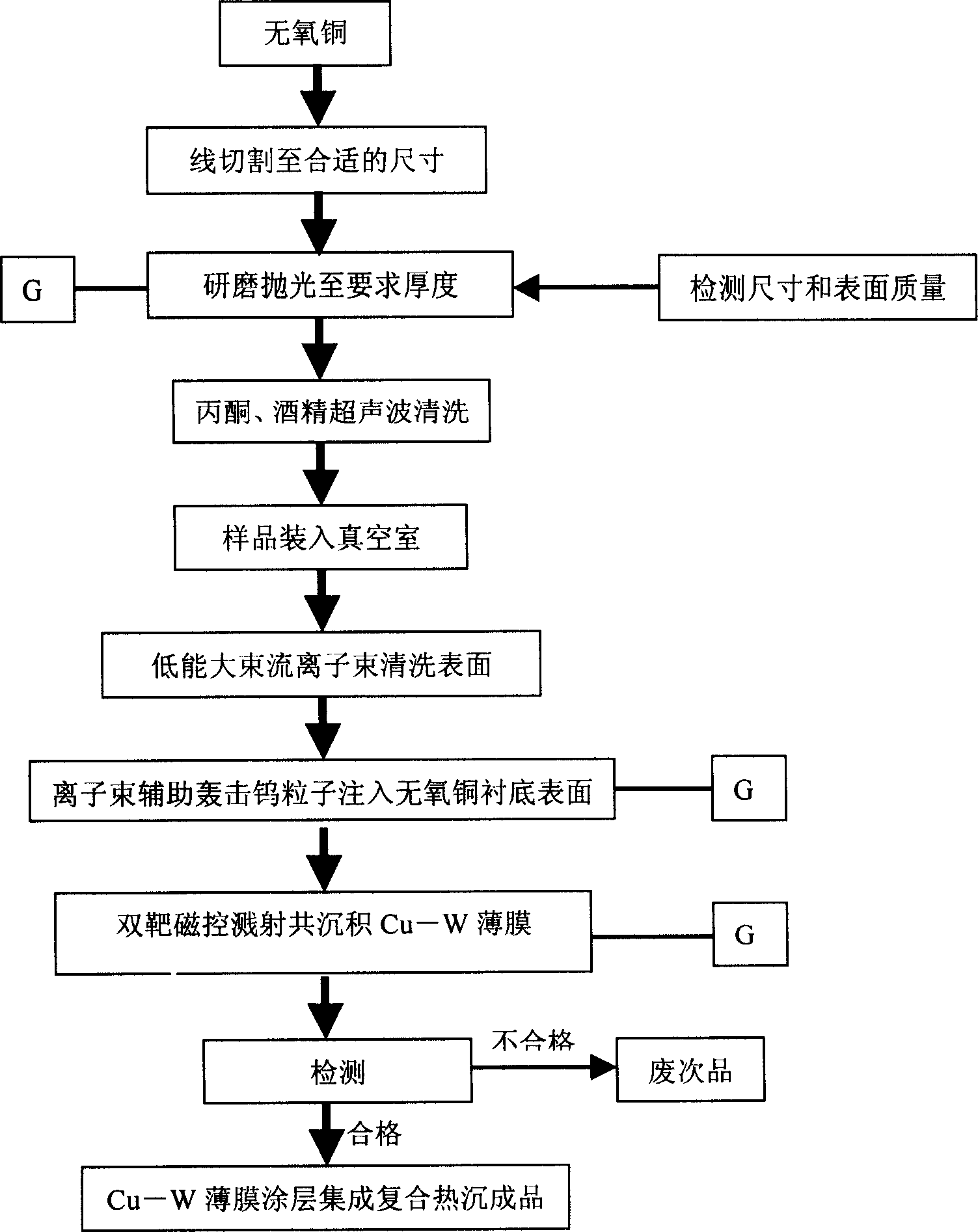

[0022] Example 1: Making a CW048 type Cu-W thin film coating composite heat sink with a Cu content of 9.45%wt;

[0023] Using the ion beam magnetron sputtering composite coating process to deposit Cu-W film on the oxygen-free copper substrate to make a composite heat sink, the main performance of the test is:

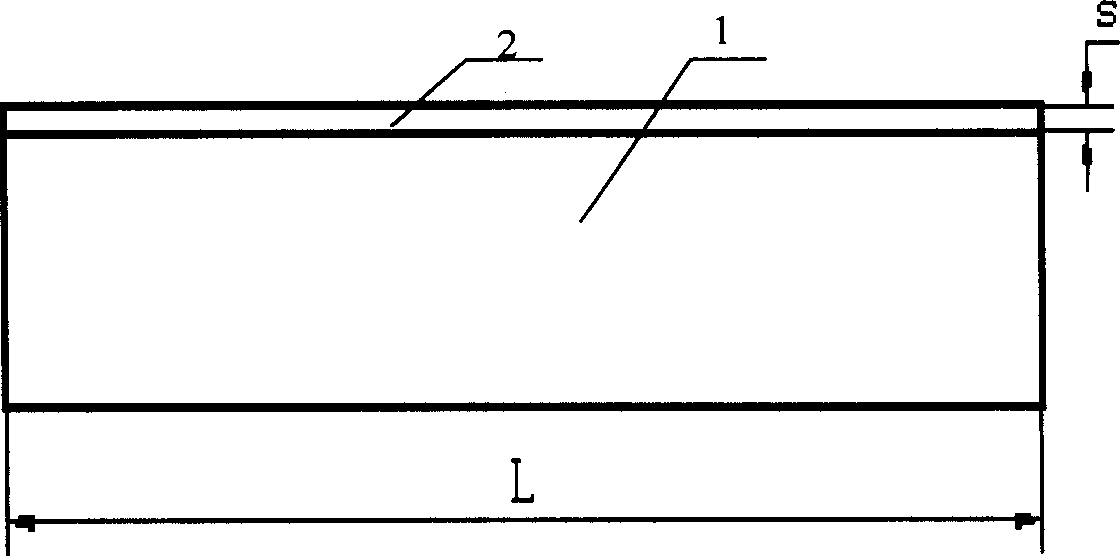

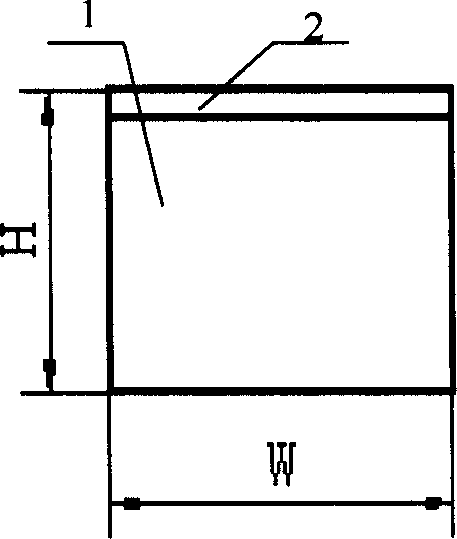

[0024] (1) The overall dimensions of the product are: 11.3mm×3.0mm×0.48mm;

[0025] (2) Thermal conductivity of composite heat sink: 328.8W / m·k;

[0026] (3) Coefficient of thermal expansion of Cu-W film coating: 6.22×10 -6 / °C;

[0027] (4) Thickness of Cu-W film coating: 9.2μm;

[0028] (5) The surface of the heat sink is smooth and bright;

[0029] (6) The film coating has high bonding strength, and it has been subjected to 20 thermal cycle tests at -10°C to 55°C, without delamination and peeling off.

[0030] The sample was sintered and packaged with laser chip GaAs, and the application test was carried out. The sample is used for heat dissipation of a single b...

Embodiment 2

[0031] Example 2: Making a CW028 type Cu-W thin film coating composite heat sink with a Cu content of 10.20%wt;

[0032] Using the ion beam magnetron sputtering composite coating process to deposit Cu-W film on the oxygen-free copper substrate to make a composite heat sink, the main performance of the test is:

[0033] 1. The overall dimensions of the product are: 11.3mm×3.0mm×0.29mm;

[0034] 2. Thermal conductivity of composite heat sink: 369.6W / m·k;

[0035] 3. Coefficient of thermal expansion of Cu-W film coating: 6.34×10 -6 / °C;

[0036] 4. Thickness of Cu-W film coating: 9.4μm;

[0037] 5. The surface of the heat sink is flat and bright;

[0038] 6. The film coating has high bonding strength, and it has been subjected to 20 thermal cycle tests at -10°C to 55°C without delamination and peeling off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com