Method for preparing room temperature ferromagnetic semiconductor Co dopped TiO2 film

A semiconductor, coxti1-xo2 technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems that limit practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

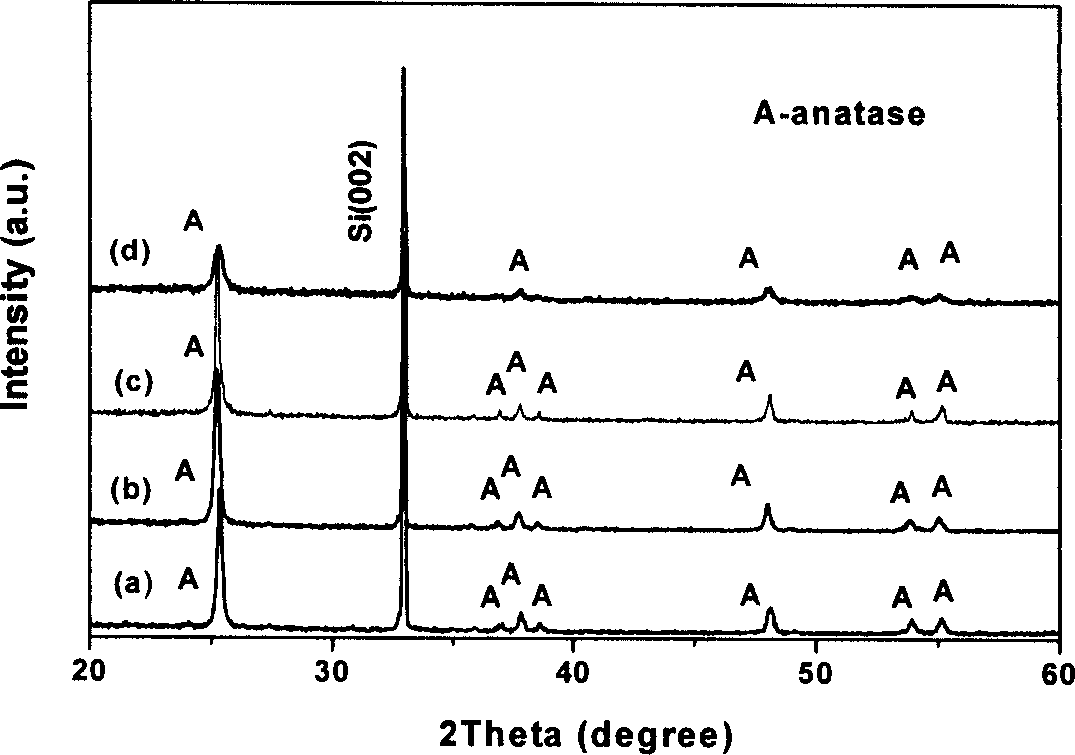

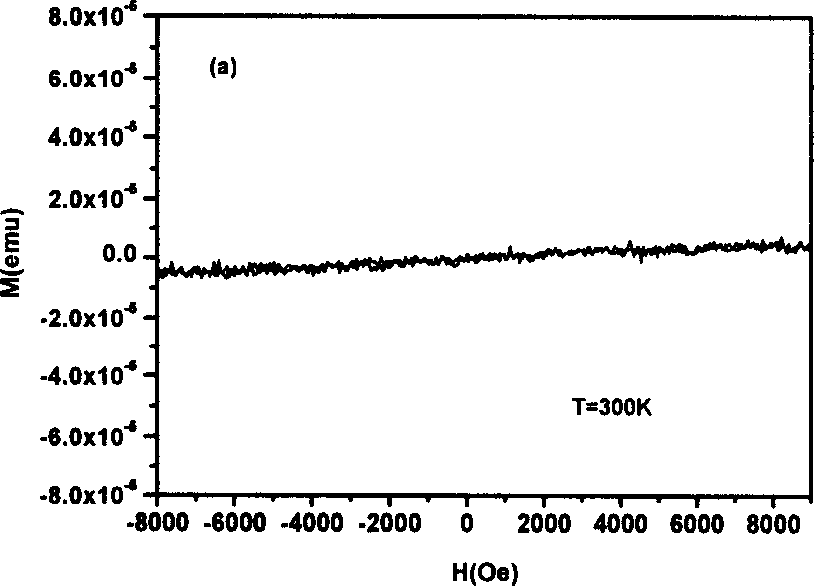

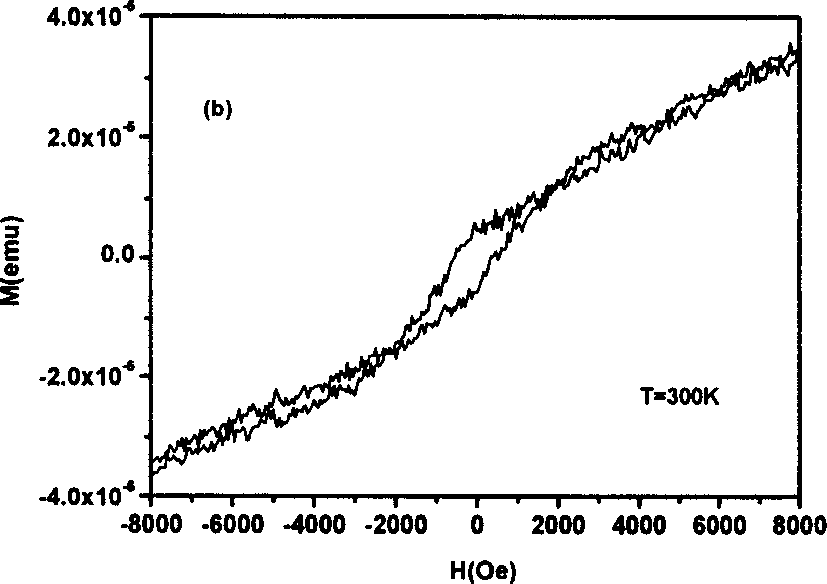

[0025] Example 1 Preparation of room temperature ferromagnetic semiconductor Co x Ti 1-x o 2 (x=0.1) film

[0026] Preparation of Co on Si(001) Single Crystal Substrate by Sol-Gel Method 0.1 Ti 0.9 o 2 film. Utilize tetra-n-butyl titanate and cobalt acetate as precursors (Co:Ti molar ratio is 1:9), dissolve them in absolute ethanol (concentration of solution is 0.1mol / L), add acetylacetone as complexing agent, nitric acid as a catalyst, drop an appropriate amount of deionized water, use a magnetic stirrer to stir the solution at room temperature for 3 hours to fully mix the solution, and place it in the air for two days to obtain stable Co-doped TiO 2 Sol. Co-doped TiO 2 The sol was coated on the Si(001) substrate, and the spin-coating process of the sol was first performed at 500 rpm for 10 seconds, and then at 3500 rpm for 60 seconds to obtain a uniform thickness of Co 0.1 Ti 0.9 o 2 film. After the film is dried at 100°C for 10 minutes, the next film spin coatin...

Embodiment 2

[0028] Example 2 Preparation of room temperature ferromagnetic semiconductor Co x Ti 1-x o 2 (x=0.05) film

[0029] Preparation of Co on Si(001) Single Crystal Substrate by Sol-Gel Method 0.05 Ti 0.95 o 2 film. Use tetra-n-butyl titanate and cobalt nitrate as precursors (Co:Ti molar ratio is 5:95), dissolve them in ethylene glycol (concentration of solution is 0.1mol / L), add glacial acetic acid as complex agent, nitric acid as a catalyst, drop an appropriate amount of deionized water, use a magnetic stirrer to stir the solution at room temperature for 3 hours to fully mix the solution, and heat and age at 60 ° C for 12 hours to obtain stable Co-doped TiO 2 Sol. Co-doped TiO 2 The sol was coated on the Si(001) substrate, and the spin-coating process of the sol was first performed at 500 rpm for 10 seconds, and then at 3500 rpm for 60 seconds to obtain a uniform thickness of Co 0.05 Ti 0.95 o 2 film. After the film is dried at 80°C for 15 minutes, the next film spin ...

Embodiment 3

[0030] Example 3 Preparation of room temperature ferromagnetic semiconductor Co x Ti 1-x o 2 (x=0.15) film

[0031] Preparation of Co on Si(001) single crystal substrate by sol-gel method 0.15 Ti 0.85 o 2 film. Utilize tetra-n-butyl titanate and cobalt chloride as precursors (Co:Ti molar ratio is 15:85), dissolve them in absolute ethanol (concentration of solution is 0.1mol / L), add acetylacetone as complex Mixture, hydrochloric acid as a catalyst, drop an appropriate amount of deionized water, use a magnetic stirrer to stir the solution at room temperature for 3 hours to fully mix the solution, and heat and age at 60°C for 12 hours to obtain stable Co-doped TiO 2 Sol. Co-doped TiO 2 The sol was coated on the Si(001) substrate, and the spin-coating process of the sol was first performed at 500 rpm for 10 seconds, and then at 4000 rpm for 60 seconds to obtain a uniform thickness of Co 0.15 Ti 0.85 o 2 film. After the film is dried at 120°C for 10 minutes, the next fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com