Projected electrode based on polymer substrate, its making method and use

A technology of protruding electrodes and polymers, applied in applications, printed circuit manufacturing, electrical components, etc., can solve problems such as limiting the effect of nerve stimulation or signal recording, and achieve the effect of improving the effect and simple electrode preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

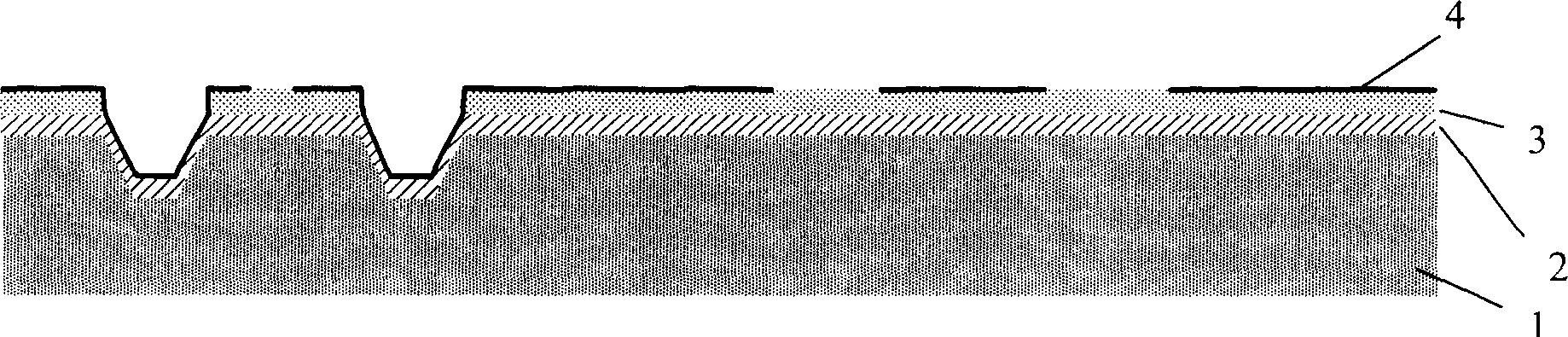

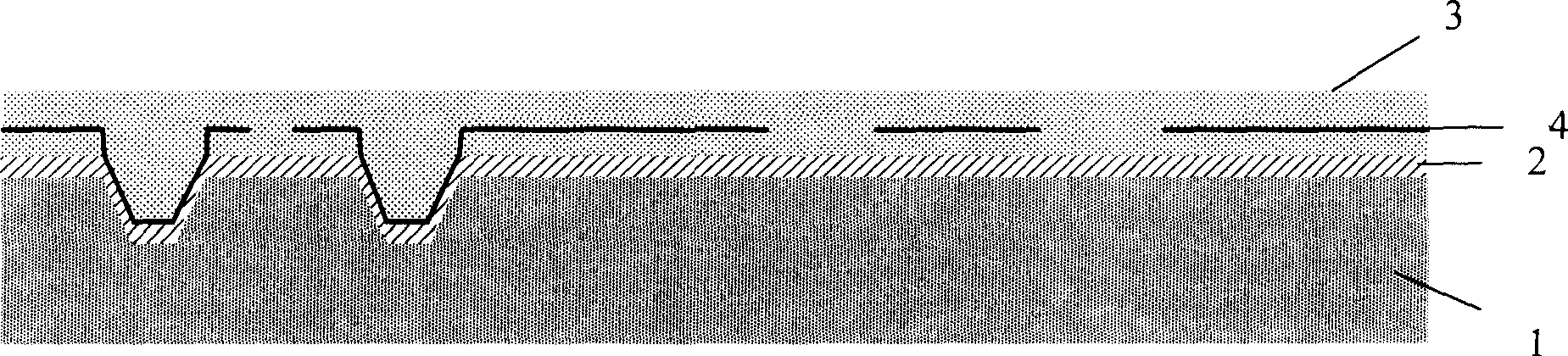

[0035]The preparation method of the raised electrode based on the polymer substrate of the present invention will be further described below by using polyimide polymer and grade 6809 optical dissection glue in conjunction with the accompanying drawings.

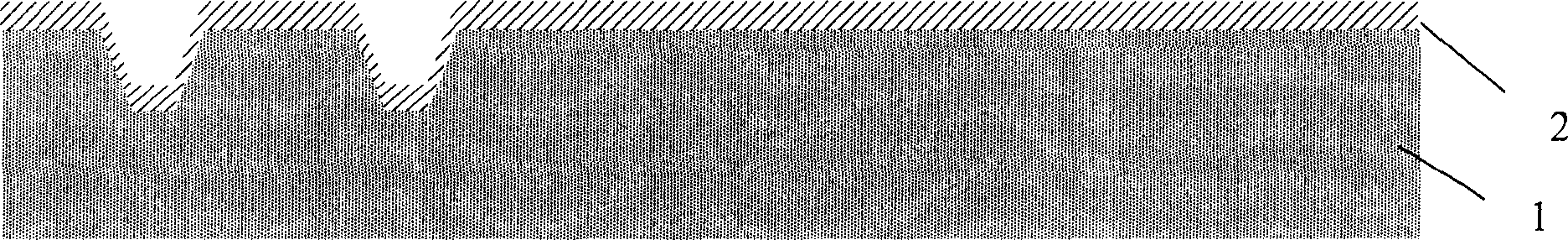

[0036] 1. Clean the silicon wafer, double-sided silicon oxide wafer, the thickness of the oxide layer is 1000 Ȧ;

[0037] 2. Bake the silicon wafer at 120°C for 20 minutes, spin-coat 6809 photoresist (3000 rpm, 30 seconds) on one side of the oxide layer of the silicon wafer, and bake at 80°C for 20 minutes;

[0038] 3. Spin-coat 6809 photoresist on the other side of the silicon wafer (3000 rpm, 30 seconds), pre-bake at 80°C for 20 minutes, expose, develop, and then bake at 120°C for 30 minutes to obtain the electrode protrusion corresponding to the stimulation point window graphics;

[0039] 4. In a shaker, a buffer solution of hydrofluoric acid (BOE, HF:NH 4 F: DI = 3: 6: 9) Soak the silicon wafer for 10 minutes, transfer ...

Embodiment 2

[0052] The protruding electrode on the polymer substrate prepared in Example 1 is applied to peripheral nerve stimulation, and the method is as follows: the polymer substrate with the protruding electrode is bonded to the stretched silicone rubber film, and the silicone rubber shrinks to form a Figure 5 Cylindrical structure shown. The cylindrical structure can wrap the nerve, and the raised electrode structure ensures good contact between the electrode stimulation point and the nerve, and implements more effective electrical signal stimulation.

Embodiment 3

[0054] The polymer base raised electrode prepared in Example 1 is applied to a visual prosthetic optic nerve stimulator in the following manner: the optic nerve 6 is cut open through surgery, and the polymer base 3 made with the raised electrode is inserted into the nerve incision (such as Figure 6 shown), and the incision was sutured, and the external electrical signal was introduced through the cable 7 connected to the protruding electrode. The protruding electrode structure ensures good contact between the electrode stimulation point and the inner nerve bundle of the optic nerve. Effective electrical signal stimulation can be implemented at a lower voltage, which reduces the damage to surrounding tissues caused by electric field and electric heat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com