Process for preparing solid phase polypeptide synthetic eptifibatide

A technology of solid-phase peptide synthesis and Effibate, which is applied in peptide preparation methods, chemical instruments and methods, and peptides, and can solve problems such as difficult source of raw materials, use, and difficulty in preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

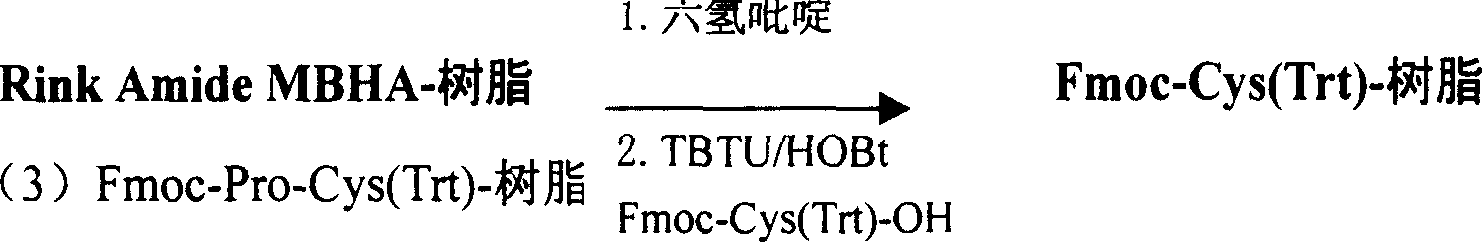

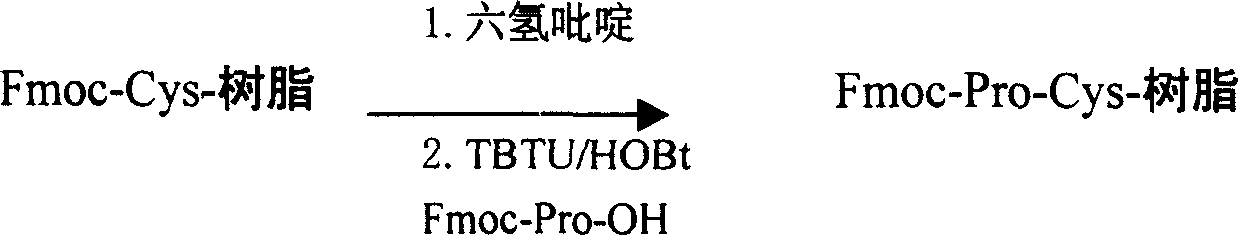

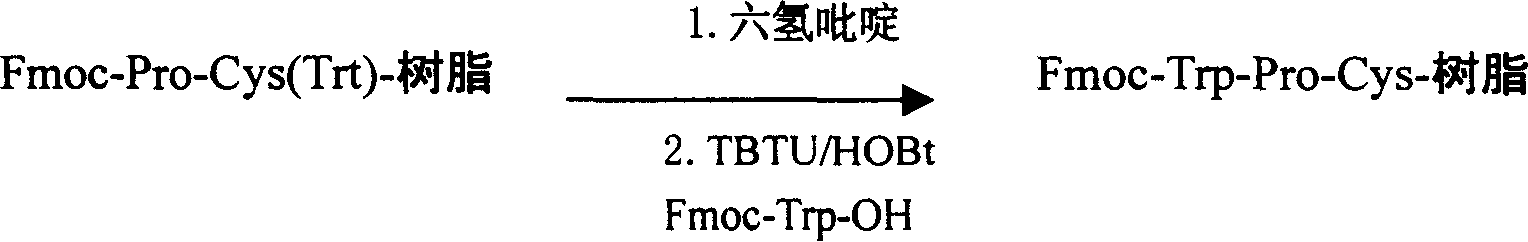

[0122] Peptide chain preparation:

[0123] Weigh 72 grams of Rink Amide MBHA resin (150 mesh, 0.86mmol / g, 61.9mmol), put it into a dedicated reactor, turn on the main power supply of the synthesizer, turn on the workstation, call the pre-written peptide receiving program, soak it with 800mlDMF, Make the resin fully swell and blow dry with nitrogen. Add 800 ml of 20% hexahydropyridine in DMF and shake at 25°C for 35 minutes. Hexahydropyridine was blown and filtered with nitrogen, washed with DMF and DMF three times, and dried with nitrogen.

[0124] Preparation of Fmoc-Cys(Trt)-resin:

[0125] Add Fmoc-Cys(Trt)-OH (MW: 585.7, 2-6 times the moles of the resin) 108.9g, TBTU (MW: 321, 2-6 times the moles of the resin) 59.7g, HOBT (MW: 135.1, 2-6 times the number of moles of resin) 25.1g, NMM 41.4ml (MW=101.2), 400ml DMF, the mixture was shaken at 25°C for 1 hour. Blow dry with nitrogen, wash with DMF three times, and blow dry with nitrogen.

[0126] Add 500 ml of 20% hexahydrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com