Non-aqueous electrolyte rechargeable battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte storage batteries, secondary batteries, secondary battery manufacturing and other directions, can solve the problem of sacrificing the high capacity characteristics of SiO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

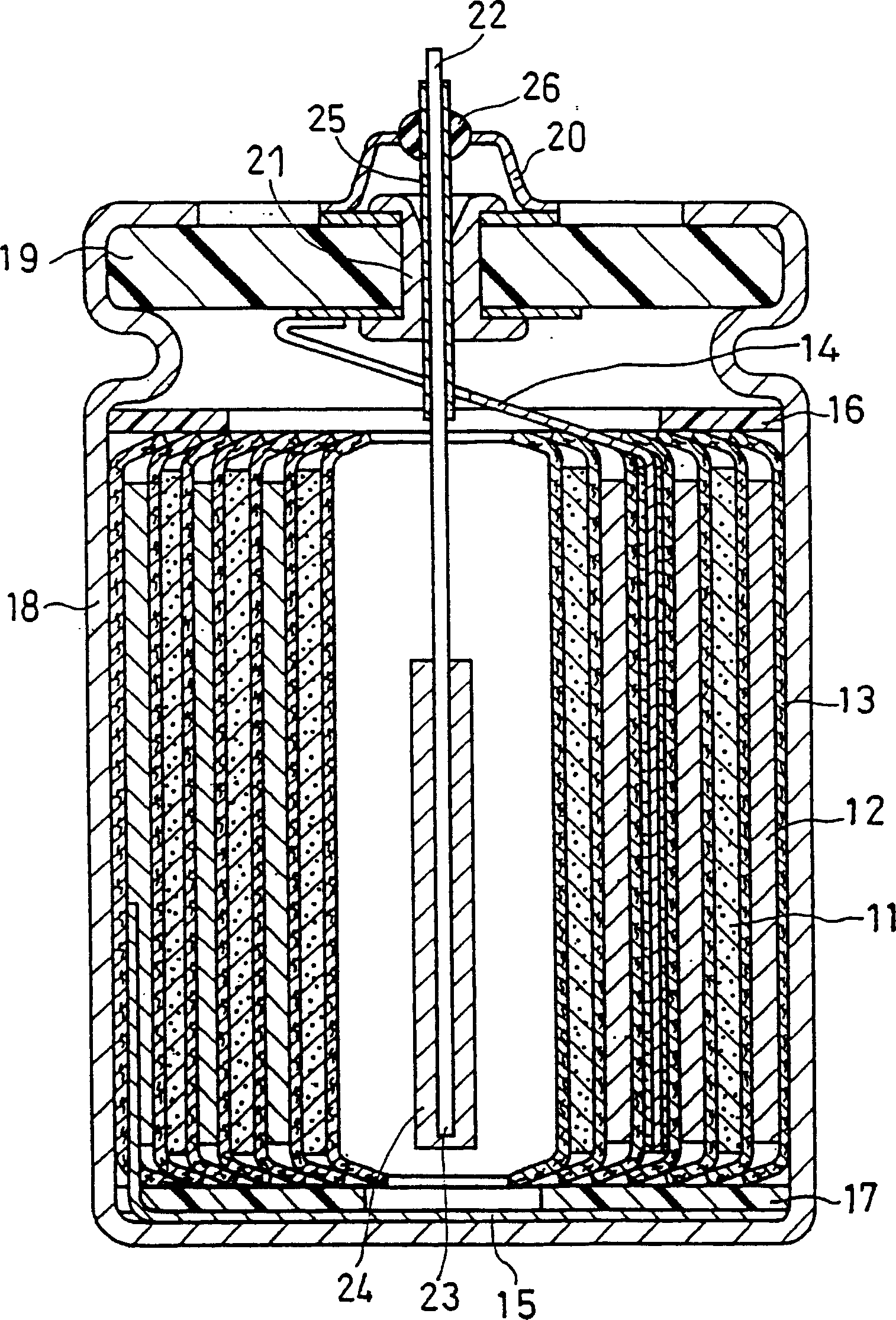

[0060] In this example, negative electrodes and cylindrical batteries were produced in the following manner, and their cycle life and discharge capacity were evaluated.

[0061] (1) Production of negative electrodes

[0062] Negative pole (i)

[0063] A graphite crucible and an electron gun in which Si metal (purity 99.999%, Furuuchi Chemical Corporation, ingot) were placed were placed in a vapor deposition apparatus. An electrolytic copper foil (20 μm thick, available from Furukawa Circuit Foil Co., Ltd.) used as a current collector sheet was fed from a roll to a vapor deposition apparatus at a constant speed (5 cm / min) so that Si deposited on the copper foil surface. The deposition conditions were set at an accelerating voltage of -8 kV and a current of 150 mA. The vacuum degree in the device is set to 3×10 when performing the following vapor deposition -5 Torr, unless otherwise specified.

[0064] After completion of deposition on one side of the current collector sheet,...

Embodiment 2

[0112] In this example, the acid content of the non-aqueous electrolyte was investigated. Using the negative electrode of Battery 9, a cylindrical lithium ion secondary battery was produced in the same manner as in Example 1. More specifically, Batteries 20 to 25 were produced by changing the drying conditions of the negative electrode (ii) (vacuum drying at 190° C. for 12 hours) as shown in Table 2. Table 2 presents the measured electrolyte acid content and battery characteristics.

[0113]

negative pole

drying conditions

acid content

(ppm)

discharge capacity

(mAh)

storage period

(V, relative to

Li / Li + )

recovery rate

(%)

after 100 cycles

Capacity retention

(%)

battery 20

Negative pole (ii)

Dew point is -60°C or

lower dry

Atmosp...

Embodiment 3

[0118] In this example, the influence of impurities contained in the negative electrode was investigated. The preparation method of the negative electrode active material used in the present embodiment is the same as that in the negative electrode (ii), except that the balls used in the mechanical manufacturing alloy are made of S45C steel (Fe-0.45%C steel) instead of stainless steel, Increase the operating time to 80 hours, 100 hours or 150 hours. The obtained alloy has a wide particle size distribution of 0.5 μm to 80 μm. These were sieved with a sieve (10 μm or less) to obtain an alloy material having a maximum particle size of 8 μm and an average particle size of 5 μm. The alloy powders thus obtained are referred to as alloy "b", alloy "c" and alloy "d".

[0119] The impurities of these alloys "b"~"d" were measured by ICP spectrometer, and it was found that transition metal elements other than Fe were lower than the lower limit of measurement. The Fe content is 680p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com