Method for preparing Nano/micro crystal of rare earth vanadate from oxide as precursor body under low temperature

A rare earth vanadate and oxide technology, applied in the field of materials, can solve the problems of unfavorable environmental protection, rational application of resources, high equipment performance requirements, large energy consumption, etc., and achieves convenient industrial transformation, convenient operation and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

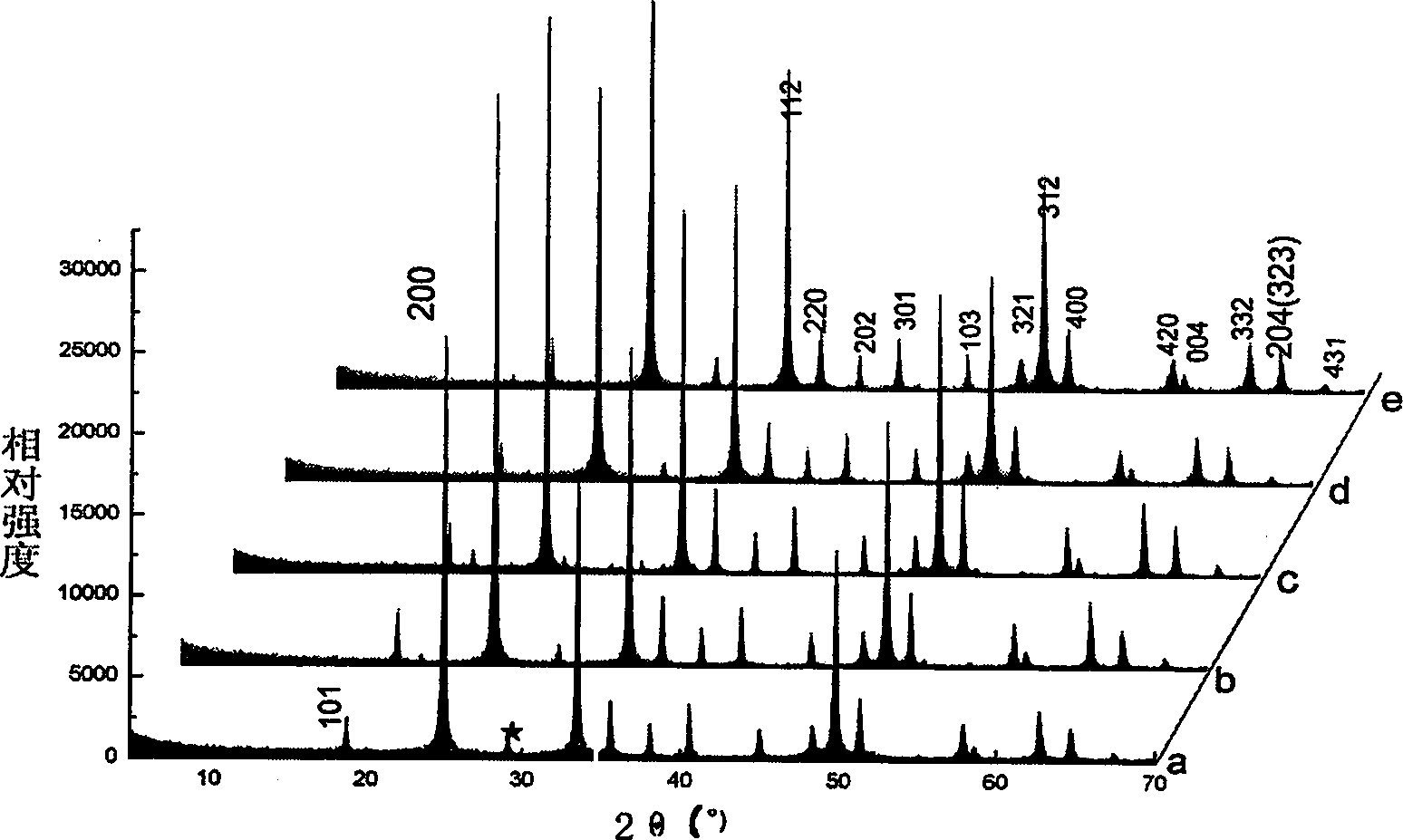

[0036] Embodiment 1: prepare yttrium vanadate

[0037] Add 1.0×10 -4 mol of Y 2 o 3 , 1.2×10 -4 mol of V 2 o 5 , 7ml of deionized water, and then add additives, the addition of additives is (a) 0.05mL of 1M nitric acid and 0.5×10 -4 mol EDTA, (b) without any additives, (c) 0.05mL of 1M hydrochloric acid, (d) 0.05mL of 1M hydrochloric acid, 0.5×10 -4 mol EDTA, (e) add 1M sulfuric acid 0.05mL and 0.25×10 -4 mol of EDTA, sealed reactor; transferred the reactor to an ultrasonic generator, ultrasonicated for 10 minutes, then transferred the reactor to a constant temperature drying oven, and controlled the reaction temperature to 130°C and 170°C at a heating rate of 10°C / min. ℃, 170℃, 170℃, 200℃, and heated at constant temperature for 48 hours, 24 hours, 24 hours, 24 hours, 24 hours respectively.

[0038] Step 5: After the reaction is completed, take out the reactor and let it cool down to room temperature naturally.

[0039] Step 6: Take out the precipitate obtained from t...

Embodiment 2

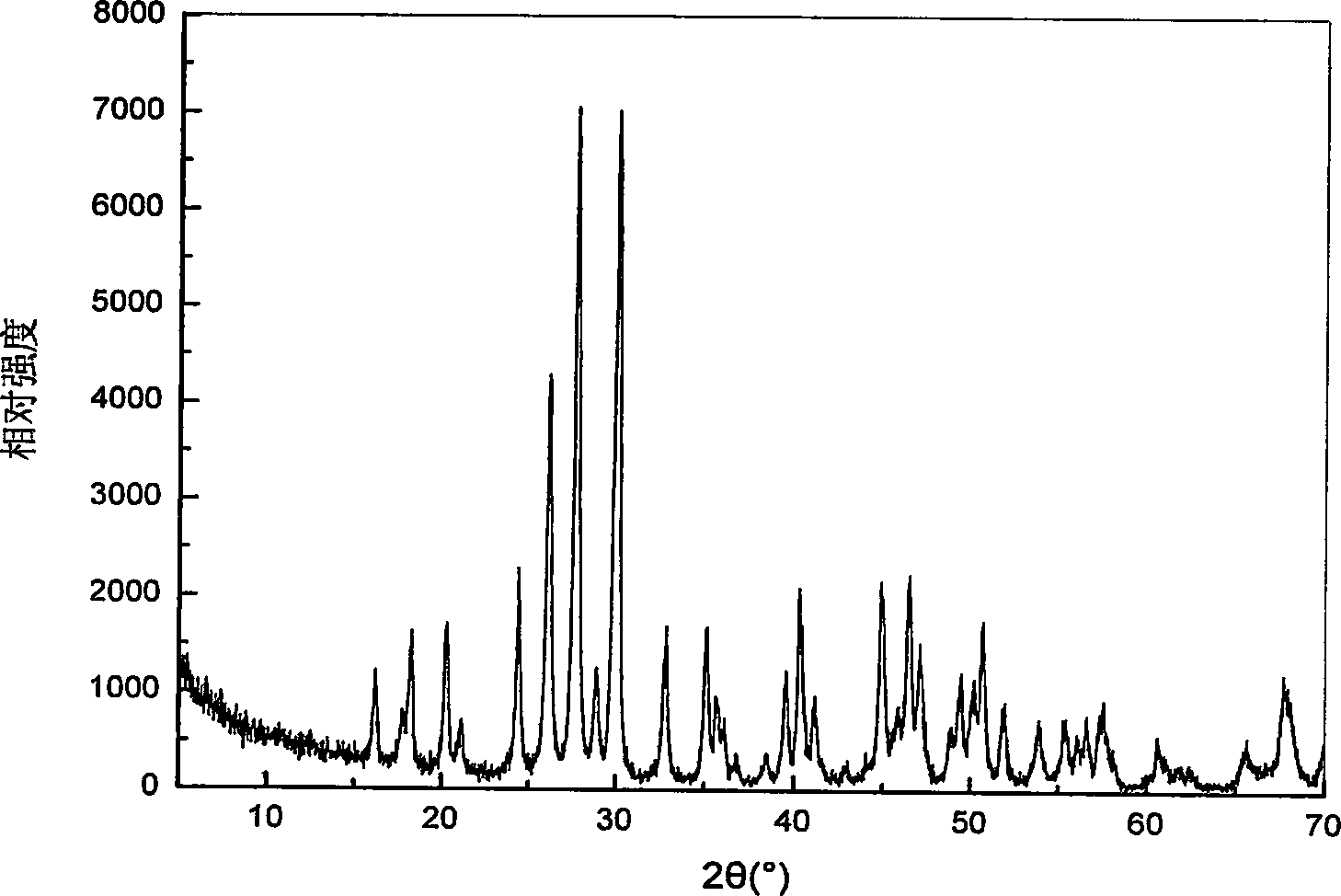

[0041] Embodiment 2: Preparation of monoclinic lanthanum vanadate

[0042] Take 1.0×10 respectively -4 mol of La 2 o 3 and V 2 o 5 As raw material, 6 mL of deionized water, 0.05 mL of 1M hydrochloric acid and 0.05×10 -4 mol KCN, according to the steps described in Example 1, the reaction temperature was 170° C., and the reaction time was 24 hours to obtain the desired product. figure 2 The X-ray diffraction pattern of the obtained product given in, finds by retrieval, the product is the LaVO of pure monoclinic system 4 . There is obvious broadening phenomenon in the spectrogram, indicating that the product is a nanoscale particle. The TEM of the product further confirms that it is a rod-shaped single crystal at the nanoscale.

Embodiment 3

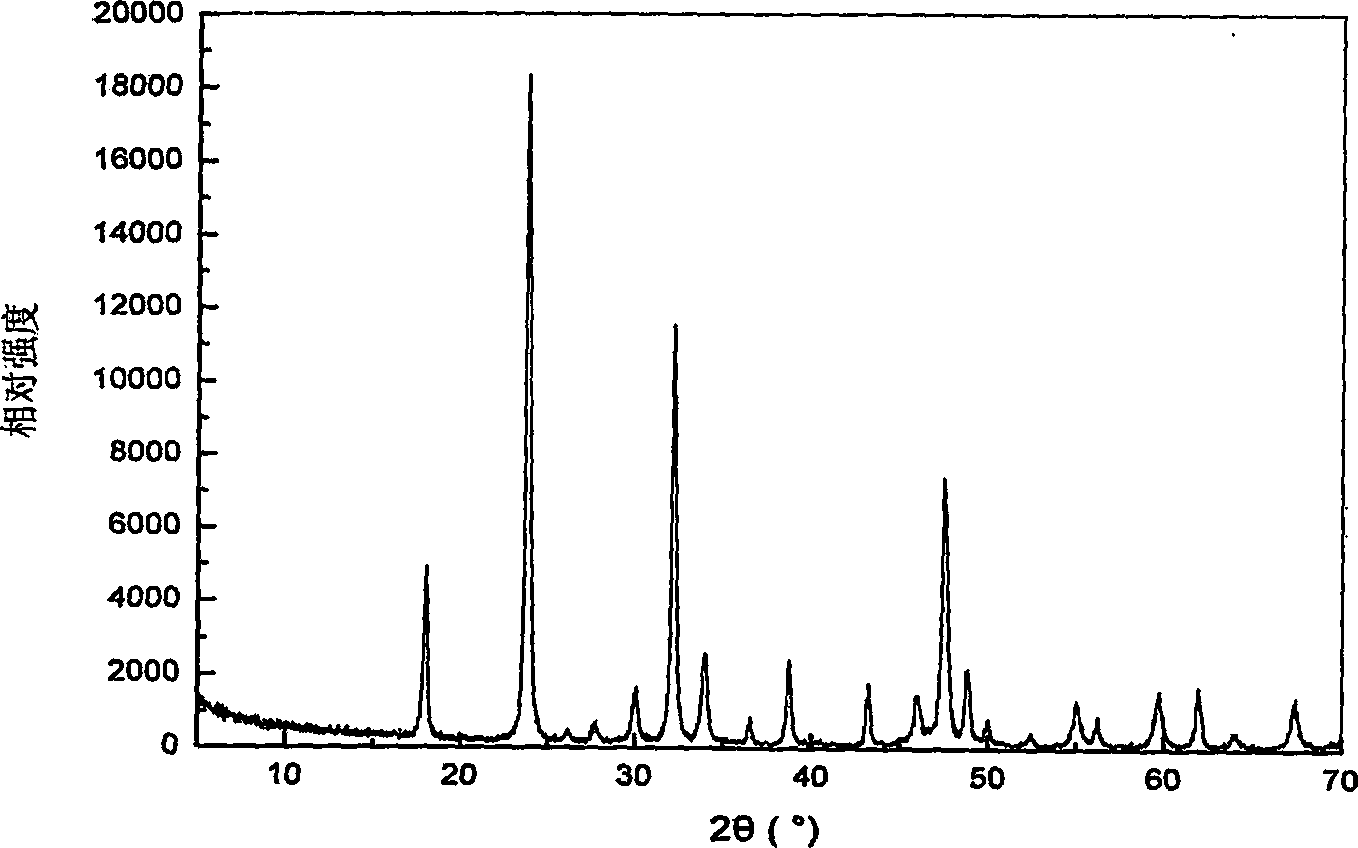

[0043] Embodiment 3: Preparation of tetragonal lanthanum vanadate

[0044] Take 1.0×10 respectively -4 mol of La 2 o 3 and V 2 o 5 As raw material, deionized water 6mL, additive EDTA0.5×10 -4 mol and 0.05mL1M nitric acid, according to the steps described in Example 1, the reaction temperature is 170 ° C, and the reaction times is 24 hours to obtain the desired product. From image 3 The X-ray diffraction spectrum of the obtained product given in , found by retrieval, the product is the LaVO of tetragonal crystal system 4 . There is obvious broadening phenomenon in the spectrogram, indicating that the product is a nanoscale particle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com