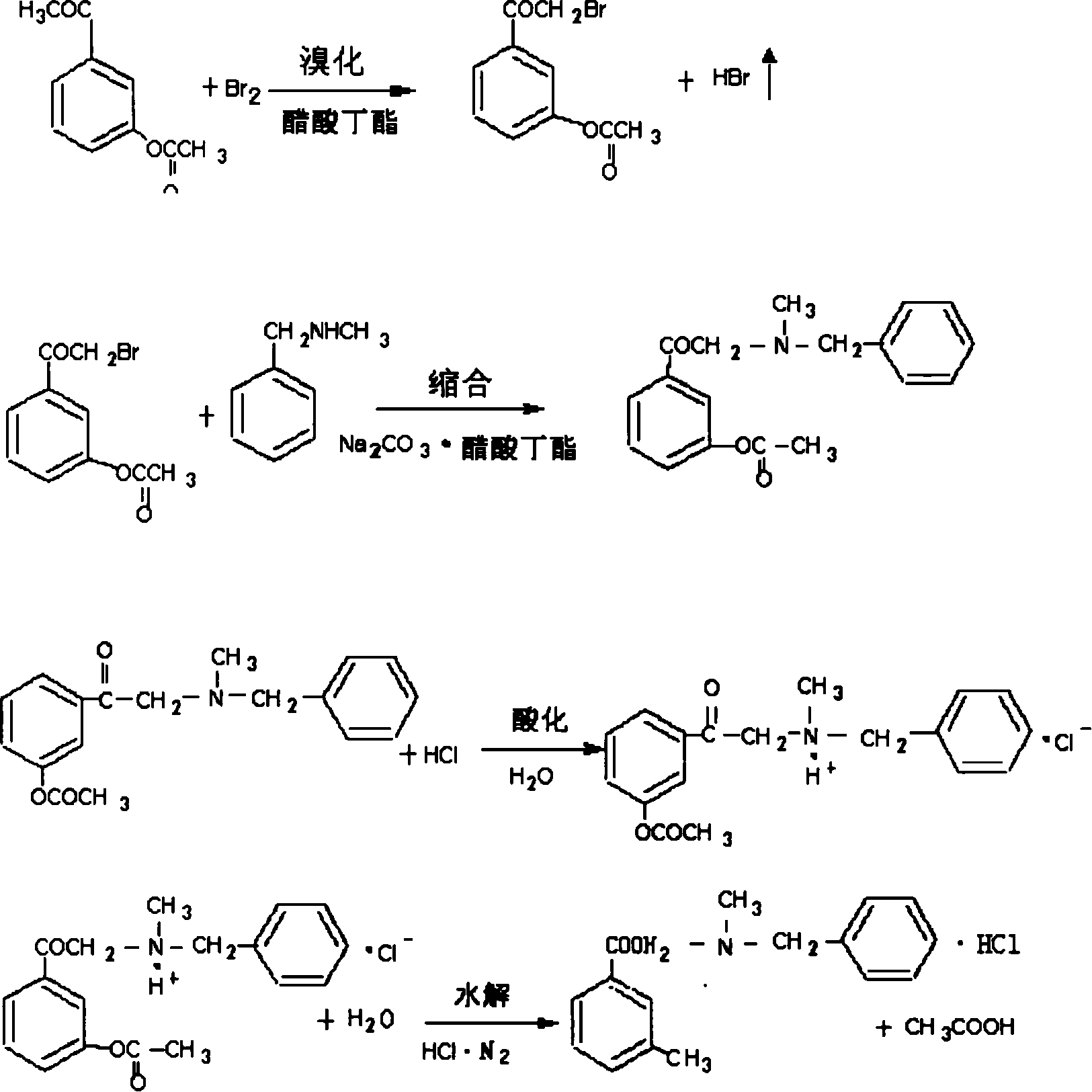

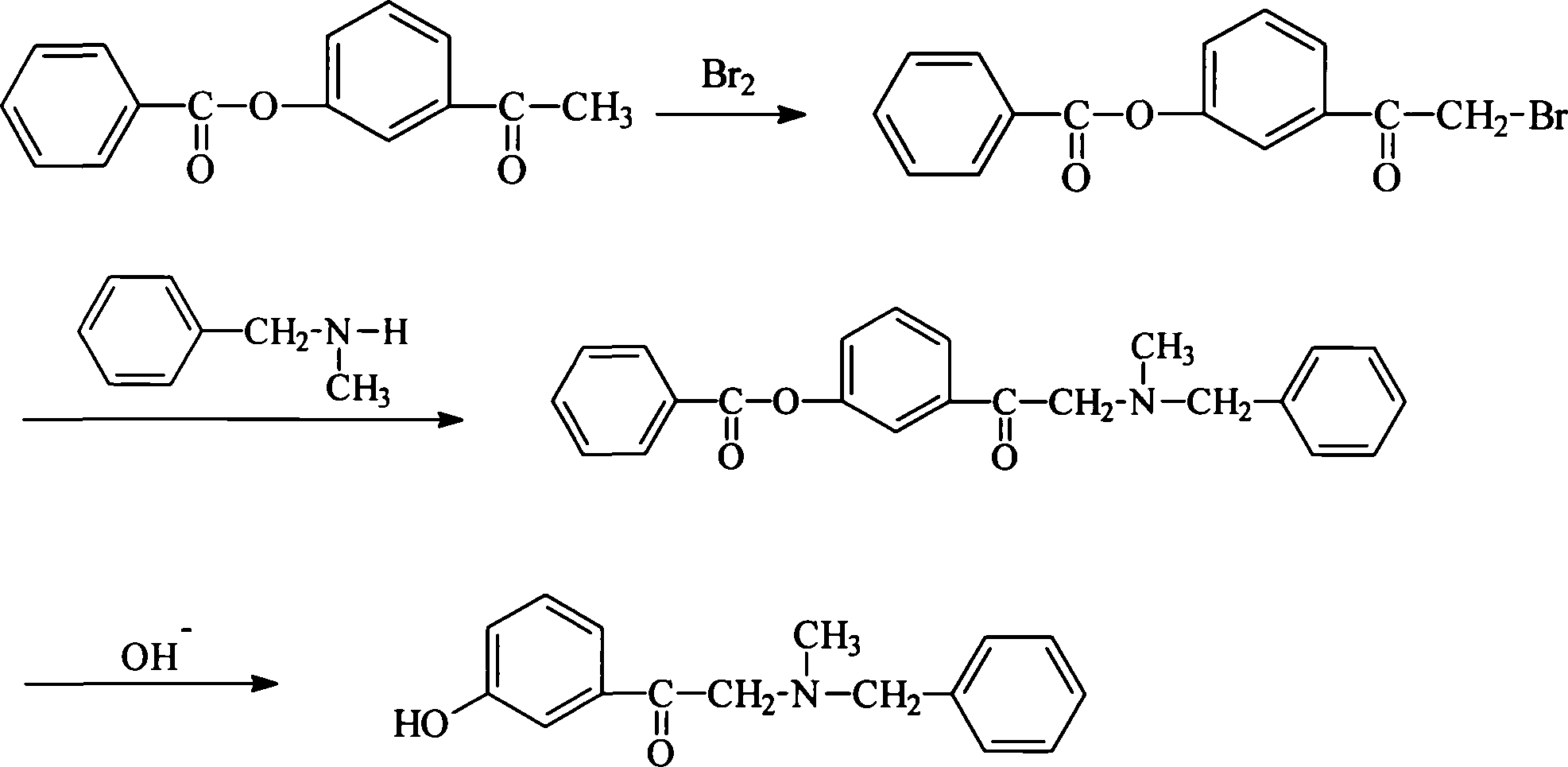

Process for synthesizing alpha-(N-methyl-benzyl)-3-hydroxy acetophenone

A technology of hydroxyacetophenone and its synthetic method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve the problem of low product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

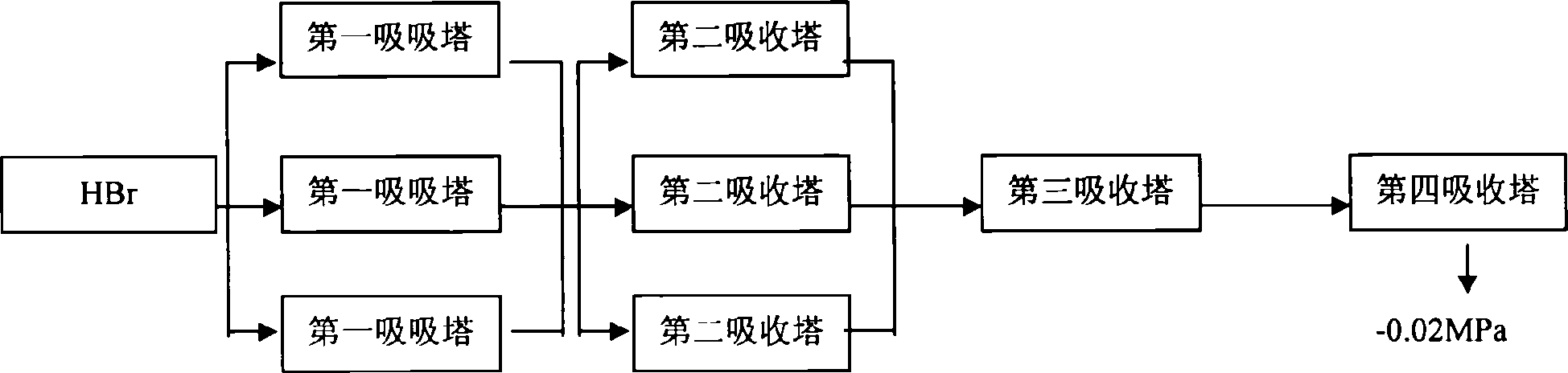

Method used

Image

Examples

Embodiment

[0040] Feeding amount of wet crude product (single pot)

[0041] Butyl acetate: 300kg (one barrel) Nitrogen: 3 bottles

[0042] 3-Acetoxyacetophenone: 178kg

[0043] Bromine: 160kg

[0045] N-Methylbenzylamine: 121kg Butyl acetate: 300kg

[0046] Hydrochloric acid: 100kg

[0048] 1. Put 300kg of butyl acetate and 178kg of 3-acetoxyacetophenone into a 500L reaction pot, stir for 15 minutes, and add dropwise 160kg of bromine previously pumped into the high level tank at an internal temperature of 20°C. Reclaim hydrogen bromide gas with low vacuum four-stage low-cooled water absorption device, dropwise, keep warm for 5 minutes, cool to 20°C, discharge to 1000L reaction pot (wherein there is 100kg of water at 0°C), after discharging, continue to stir for 5 Minutes, let stand for 30 minutes, separate the lower water layer, extract the water layer with 100kg of hydrochloric acid and recover butyl acetate once, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com