Nanometer zirconium dioxide particle capable of dispersing in organic medium and its production method

A technology of nano-zirconia and organic compounds, applied in the field of nano-materials, can solve the problems that nano-zirconia cannot be dispersed or the dispersion effect is not good, and the performance and application are limited. Uniform effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

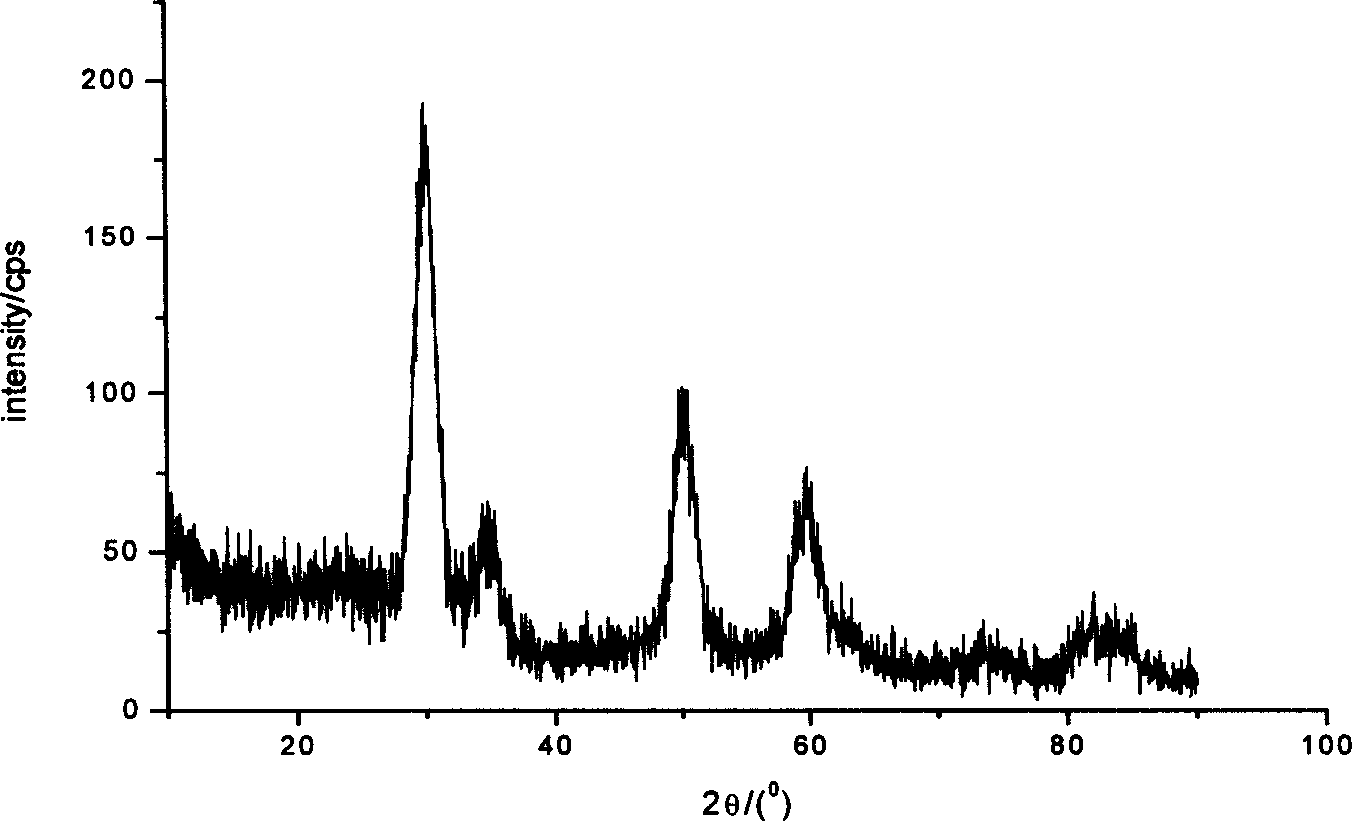

[0018] Embodiment 1, get 19.32gZrOCl 2 .8H 2 O and 0.68gY (NO 3 ) 3 .6H 2 O was dissolved in 60ml of pure water to make solution 1; 20ml of ammonia water and 50ml of pure water were taken to make solution 2; solution 1 and 2 were dripped into 100ml of pure sodium dodecylbenzenesulfonate containing a small amount of sodium dodecylbenzenesulfonate while stirring at a high speed. In water, the drip rate is 1 drop / second. After the dropwise addition is completed, react at a constant temperature of 20°C for 2 hours; filter the obtained precipitate and wash until free of Cl - exists, the filter cake is dispersed in 200ml pure water, transferred to a 250ml three-necked flask, and 5mlA-151 (C 2 h 3 Si(OEt) 2 ), and add a small amount of sodium dodecylbenzenesulfonate. Use ammonia water to adjust the pH of the solution to 9; react at a constant temperature of 50°C for 2 hours, raise the temperature to 60°C for 2 hours, and then react at 70°C for 2 hours. Filter, dry at 110° C....

Embodiment 2

[0019] Embodiment 2, get 4.83gZrOCl 2 .8H 2 O and 0.57gY(NO 3 ) 3 .6H 2 O was dissolved in 20ml of pure water to make solution 1; 13.3ml of ammonia water and 20ml of pure water were taken to make solution 2; solutions 1 and 2 were dripped into 50ml of sodium dodecylbenzenesulfonate containing a small amount of sodium dodecylbenzenesulfonate while stirring at a high speed. In pure water, the dropping speed is 1 drop / second. After the dropwise addition is completed, react at a constant temperature of 20°C for 2 hours; filter the obtained precipitate and wash until free of Cl - exists, the filter cake is dispersed in 100ml pure water, transferred to a 250ml three-necked flask, and 2ml KH-550 (NH 2 (CH 2 ) 3 Si(OEt) 3 ), adjust the pH of the solution to 9 with ammonia water; react at a constant temperature of 50°C for 2 hours, raise the temperature to 60°C for 2 hours, and then react at 70°C for 2 hours. Filter, dry at 110° C. for 2 hours and pulverize to obtain a white s...

Embodiment 3

[0020] Embodiment 3, get 10.18gZr (NO 3 ) 4 and 0.34gY (NO 3 ) 3 .6H 2 O was dissolved in 60ml of pure water to make solution 1; 10ml of ammonia water and 55ml of pure water were taken to make solution 2; solution 1 and 2 were dripped into 100ml of pure sodium dodecylbenzenesulfonate containing a small amount of sodium dodecylbenzenesulfonate while stirring at a high speed. In water, the drip rate is 1 drop / second. After the dropwise addition is completed, react at a constant temperature of 20°C for 2 hours; filter the obtained precipitate and wash until free of Cl - exists, the filter cake is dispersed in 200ml of pure water, transferred to a 250ml three-necked flask, and 3ml of KH-560 (CH 2 OCHCH 2 O(CH 2 ) 3 Si(OMe) 3 ) and adjust the pH of the solution to 9 with sodium hydroxide; react at a constant temperature of 50°C for 2 hours, then heat up to 60°C for 4 hours. Filter, dry at 110° C. for 2 hours and pulverize to obtain a white solid powder. Finally, it is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com