Thermoplastic resin composition for masterbatch, process for producing molding material comprising the same, thermoplastic resin composition obtained with the same, and process for producing the compo

A technology of thermoplastic resin and composition, which is applied in the field of manufacturing chip-shaped molding materials, which can solve the problems of thermoplastic resin melt viscosity fluctuation, difficult to adjust slice shape, difficult to adjust melt viscosity, etc., and achieve good coloring resistance, easy slice shape, and transparency sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] The present invention will be specifically described below using examples, but the present invention is not limited to the examples shown below. Wherein, "parts" and "%" in each example are based on weight. In addition, each evaluation value is the value measured by the following method.

[0130] (Physical properties of thermoplastic resin composition for masterbatch, etc.)

[0131] (1) Element content: Metal zinc content and phosphorus content were measured by atomic absorption analysis.

[0132] (2) Intrinsic viscosity: Measured at 30°C with a phenol / 1,1,2,2-tetrachloroethane mixed solution (weight ratio (3 / 2)).

[0133] (3) Melt viscosity: It measured using the Toyo Seiki Co., Ltd. Cayapirograph (IC type). The inner diameter of the cylinder is 10mm. Fill the cylinder with the sample while sparging with nitrogen. Complete sample filling within 30 seconds. After filling the sample, start the measurement 3 minutes later, and finish the measurement within 3 minutes...

reference example 1

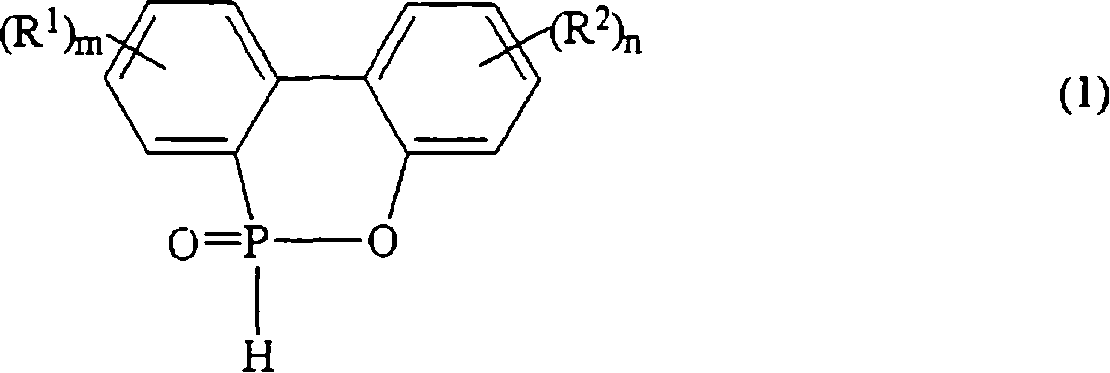

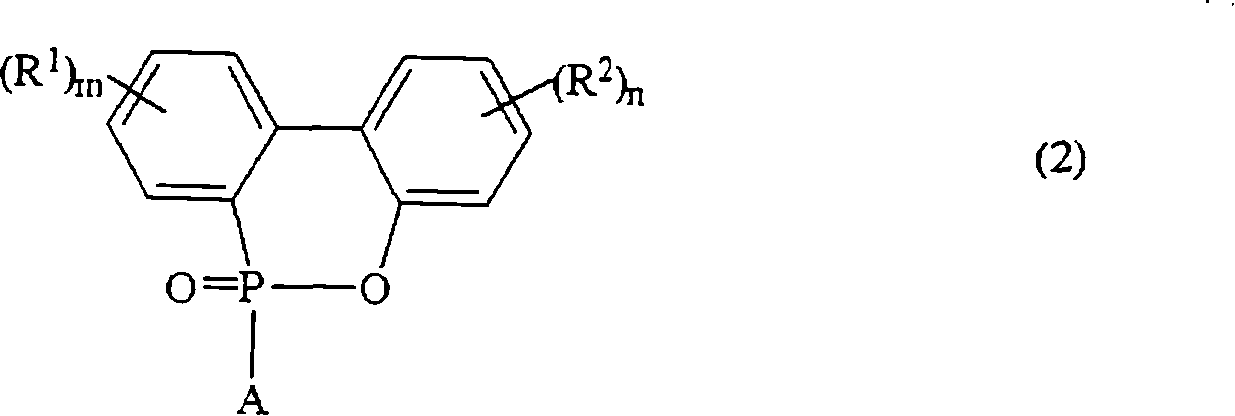

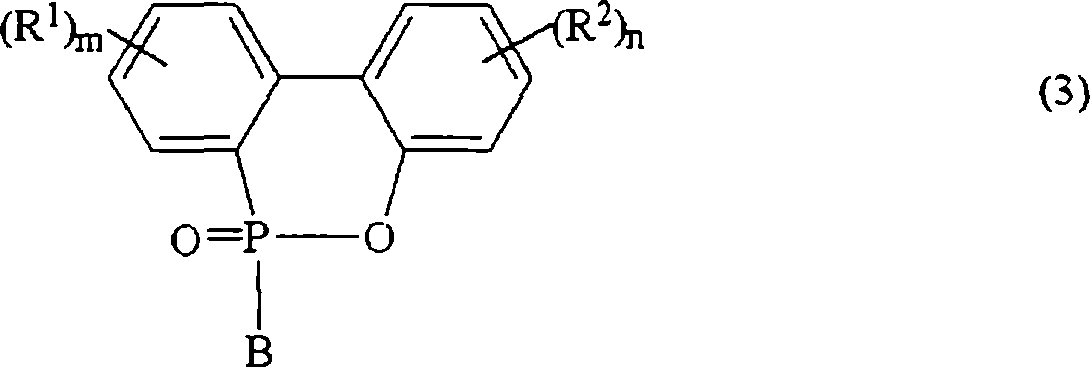

[0141] (Synthesis of organophosphorus compounds)

[0142] 4.9 parts of toluene was added to 1000 parts of crude ortho-phenylphenol (OPP) with a purity of 95%, stirred at room temperature for about 1 hour, and the supernatant was removed. Next, add 1,000 parts of o-phenylphenol and 1,009 parts of phosphorus trichloride to the reactor at a molar ratio of 1:1.25, mix at room temperature for 1 hour, then raise the temperature to 150° C. over 5 hours, at which point hydrogen chloride. Add 5.9 parts of zinc chloride to it, and react at 200°C for 4 hours to obtain 6-chloro-(6H)-dibenzo-(c,e)(1,2)-oxadiethoxyphosphorylthiochol Base (DOP-X).

[0143] To the obtained DOP-X was added 500 parts of toluene, stirred at room temperature for about 1 hour, and the supernatant was removed to purify DOP-X.

[0144] Furthermore, 77 parts of water was added thereto to make the molar ratio of water and o-phenylphenol 1:1, and 1000 parts of toluene was added, and hydrolysis was carried out under ...

Embodiment 1

[0149] (Preparation of thermoplastic resin composition (II) for masterbatch)

[0150] In a stainless steel autoclave equipped with a stirrer, a distillation tower, and a pressure regulator, put 832 parts of terephthalic acid and 1,000 parts of the organophosphorus compound (GHM) obtained in the above Reference Example 1 (50% ethylene glycol solution / With respect to the obtained polymer, the phosphorus content is 30000ppm) and 184 parts of ethylene glycol, and then add 0.62 parts of antimony trioxide and 3.26 parts of triethylamine, at 245 ° C, 2.5 kg / cm 2 Under gauge pressure, the esterification reaction was carried out for 2 hours while removing water generated by the esterification one by one. Next, the temperature of the system was raised to 275° C. over 1 hour, while the pressure of the system was gradually reduced to 0.1 mmHg, and polycondensation was carried out under these conditions until the melt viscosity reached 3500 poise (275° C.). Then, in the molten state, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com