Method for modulating light by free space coupling technology and modulator

A free-space, modulated light technology, used in instruments, optics, nonlinear optics, etc., can solve the problems of large-scale integration of devices, high modulation voltage, and limited large-scale integration, and achieve improved integration. , volume reduction, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

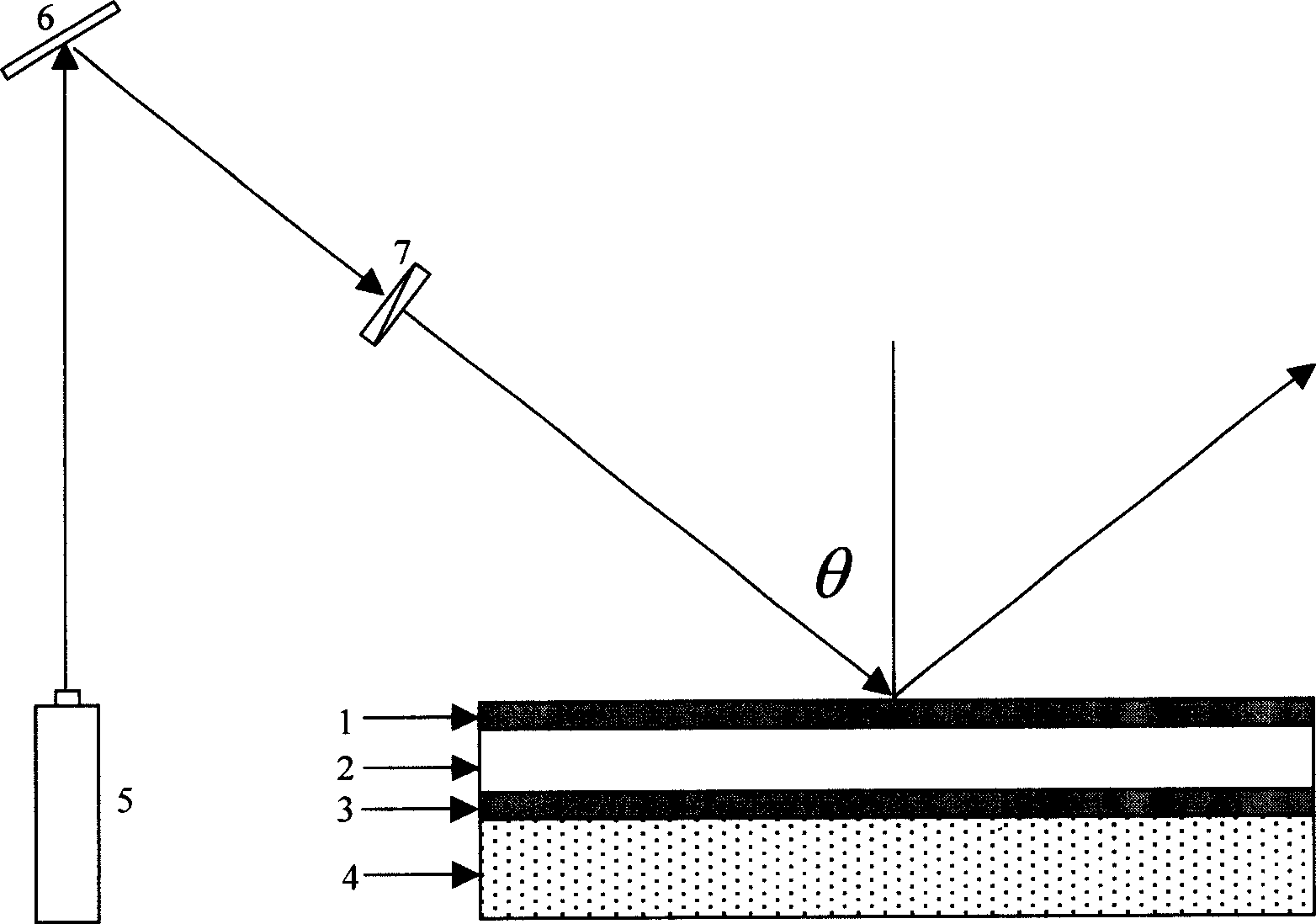

[0020] A reflective organic polymer electro-optic modulator based on free-space coupling technology is used to modulate the S-polarized laser signal with a wavelength of 832nm.

[0021] Step 1: Select K9 glass as the substrate glass, place it in acetone solution, clean it with ultrasonic waves, then clean it with deionized water and put it in an oven for drying. The lower metal film 3 is made of gold (ε=-25.2+1.6i), which is plated on the upper surface of K9 glass by sputtering, with a thickness of 300nm. The organic polymer film 2 is made of polyimide with a refractive index of 1.56, which is plated on the underlying gold film with a thickness of about 15 μm by a spin film forming method. Then, near the glass transition temperature (110°C) of the material of the organic polymer film 2, a very high DC voltage (3000V) is applied to the metal needle tip perpendicular to the surface of the organic polymer, and the poles inside the organic polymer film Sex molecules will be neatl...

Embodiment 2

[0024] The modulation of the P-polarized laser signal with a wavelength of 832nm is realized by using a reflective organic polymer electro-optic modulator based on free space coupling technology.

[0025] Step 1: Select K9 glass as the substrate glass, place it in acetone solution, clean it with ultrasonic waves, then clean it with deionized water and put it in an oven for drying. The lower metal film 3 is made of gold (ε=-25.2+1.6i), which is plated on the upper surface of K9 glass by sputtering, with a thickness of 300nm. The organic polymer film 2 is made of polyimide with a refractive index of 1.56, which is plated on the underlying gold film with a thickness of about 30 μm by a spin film forming method. Then, near the glass transition temperature (170°C) of the material of the organic polymer film 2, a very high DC voltage (3000V) is applied to the metal needle tip perpendicular to the surface of the organic polymer, and the poles inside the organic polymer film Sex mole...

Embodiment 3

[0028] A reflective organic polymer electro-optic modulator based on free-space coupling technology is used to modulate the S-polarized laser signal with a wavelength of 832nm.

[0029] Step 1: Select K9 glass as the substrate glass, place it in acetone solution, clean it with ultrasonic waves, then clean it with deionized water and put it in an oven for drying. The lower metal film 3 is made of gold (ε=-25.2+1.6i), which is plated on the upper surface of K9 glass by sputtering, with a thickness of 300nm. The organic polymer film 2 is made of polyimide with a refractive index of 1.56, which is plated on the underlying gold film with a thickness of about 20 μm by a spin film forming method. Then, near the glass transition temperature (110°C) of the material of the organic polymer film 2, a very high DC voltage (3000V) is applied to the metal needle tip perpendicular to the surface of the organic polymer, and the poles inside the organic polymer film Sex molecules will be neatl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electro-optic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com