Preparation method of high substituting degree hydroxy propyl distarch phosphate

A technology of hydroxypropyl distarch phosphate and hydroxypropyl distarch phosphate, which is applied in the field of preparation of highly substituted hydroxypropyl distarch phosphate, can solve problems such as backwardness, backward processing technology and application, and achieve Wide range of raw material sources, low cost, and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

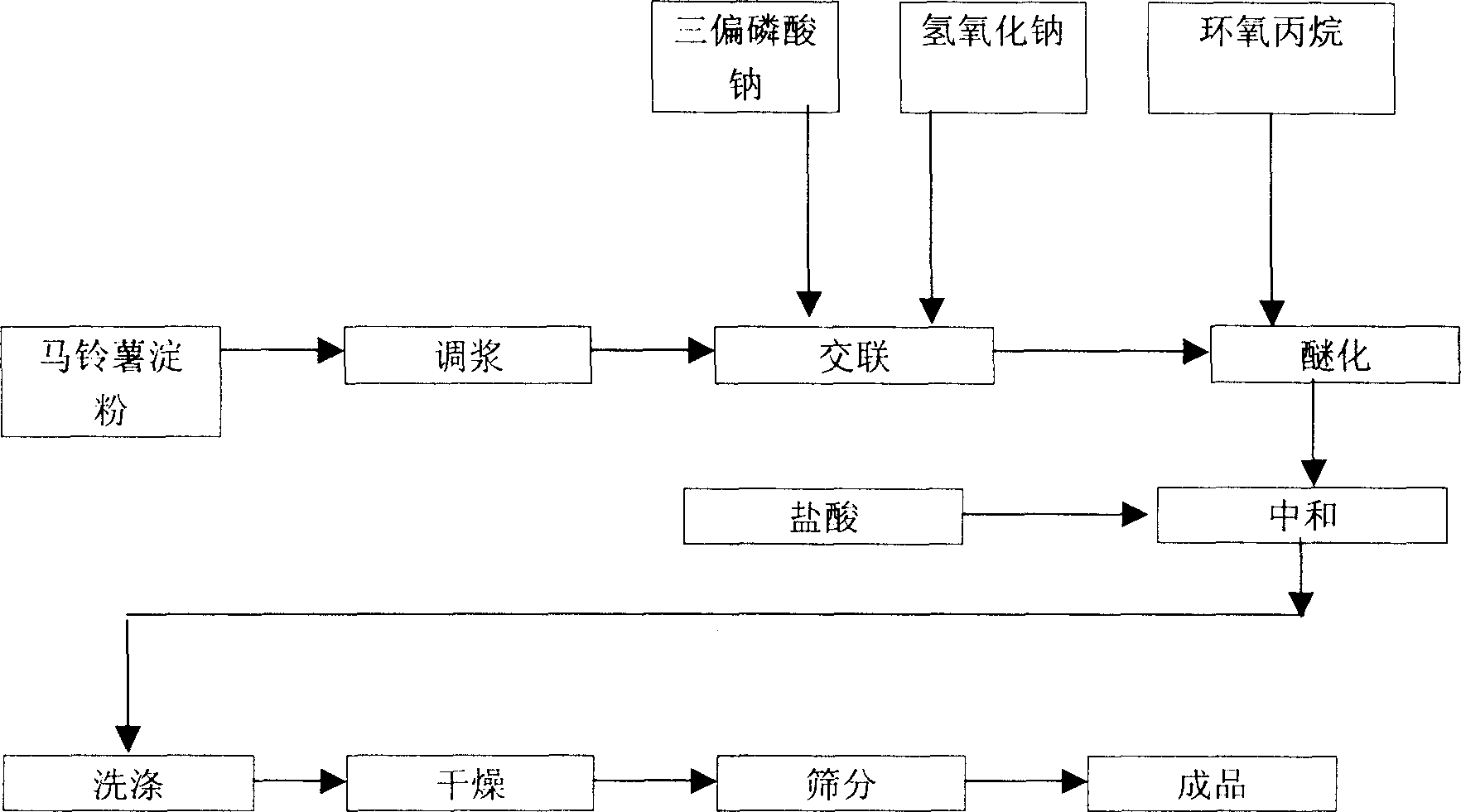

Image

Examples

Embodiment 1

[0021] Embodiment 1: at first 100 kilograms of potato starch and 10 kilograms of sodium sulfate are added 180 kilograms of water and are adjusted into the starch slurry of 20-23Be in the reactor, constantly stir, add the sodium hydroxide that mass concentration is 3-3.8% in the kettle Adjust the pH value to 11.5, then add 0.5 kg of sodium trimetaphosphate, stir for 30 minutes, add 6 kg of propylene oxide, heat up to 45-49 ° C for 21 hours. After the above-mentioned reaction finishes, be that 9% hydrochloric acid is adjusted pH value to 6.0 with mass concentration, add 200 kilograms of water washings, sedimentation in the kettle, wash again in the same way, to remove impurity (sodium sulfate, sodium chloride or other chemicals residues) to produce finished products.

Embodiment 2

[0022] Embodiment 2: step is the same as embodiment 1, difference is: the pH value of esterification reaction process remains on 11.0

Embodiment 3

[0023] Embodiment 3: step is the same as embodiment 1, and difference is: the pH value of esterification reaction process remains on 12.0

[0024] Adhesive

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com