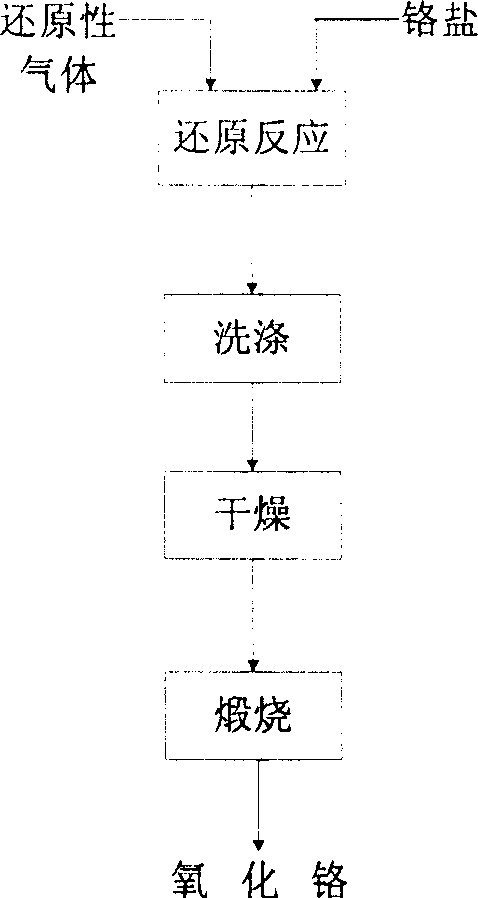

Method of preparing chromium oxide by reducing chromate with gaseous reducing agent at low temperature

A reducing agent, chromium oxide technology, applied in the direction of chromium oxide/hydrate, etc., can solve the problems of high reaction temperature, defective crystals, and great environmental harm, and achieve the advantages of simple production process, reduced reaction energy consumption, and reduced production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 15g of potassium dichromate into a material boat, put it into a tube furnace, raise the temperature to 300°C, and feed in hydrogen gas, the amount of hydrogen gas introduced is 60L / h, and react for 2 hours. After cooling down naturally, take out the reaction mixture , washed with water and filtered, dried the filter cake, and calcined in a muffle furnace for 2 hours at 400°C for thermal decomposition to obtain ultrafine chromium oxide powder with a purity of 97.9% and a particle size of about 0.2um. The scanning electron microscope photo is as follows figure 1 shown.

Embodiment 2

[0027] Weigh 15g of sodium chromate in a material boat, put it into a tube furnace, raise the temperature to 850°C, feed natural gas, the amount of natural gas fed is 60L / h, react for 30min, after natural cooling, take out the reaction mixture , washed with water and filtered, dried the filter cake, and calcined in a muffle furnace at 1100°C for 1 hour to obtain a chromium oxide powder with a purity of 99.1% and a particle size of 0.2-0.4um. The scanning electron microscope photo is as follows: figure 2 shown.

Embodiment 3

[0029] Weigh 15g of potassium dichromate in a material boat, put it into a tube furnace, raise the temperature to 400°C, feed gas, the amount of gas fed is 60L / h, react for 3h, after natural cooling, the reaction mixture Take it out, wash and filter with water, dry the filter cake, and then calcinate it in a muffle furnace at 700°C for 3 hours to obtain a chromium oxide powder with a purity of 98.5% and a particle size of 0.5um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com