Venomous snake thrombin sample enzyme modified by polyethylene glycol

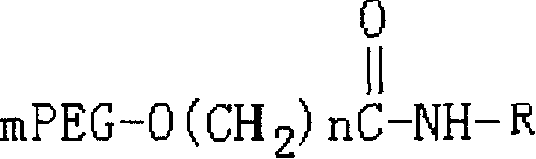

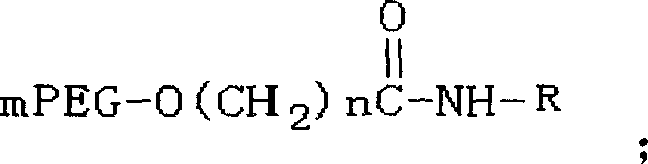

A technology of polyethylene glycol and PEGylation, which is applied in the direction of enzymes, blood diseases, enzymes, etc., can solve the problems of no further disclosure of modification sites of modified products, low sample uniformity, and no disclosure of modifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

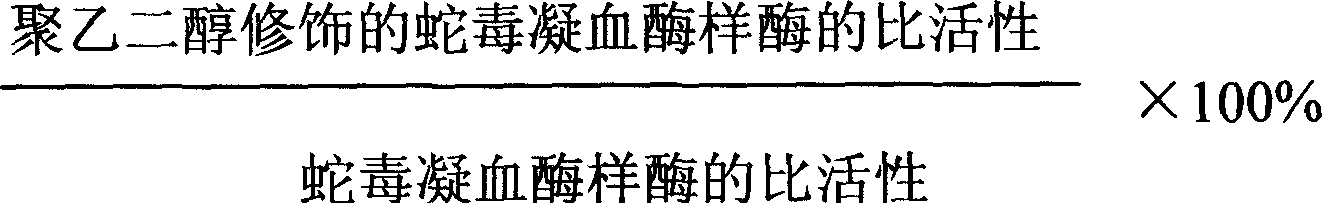

[0061] Selection of Modification Conditions of Snake Venom Thrombin-Like Enzyme by Methoxypolyethylene Glycol Succinimidyl Propionate 20000 (mPEG-SPA-20000)

[0062] Choice of reaction temperature: Take 2ml of 0.8mg / ml defibrase solution, add 2ml of phosphate buffer to make the pH of the solution 6.5, then add 8.0mg of mPEG-SPA-20000 solid, dissolve, mix well, take 0.3 for each ml was placed in 4 test tubes with stoppers, and then placed at 4°C, 10°C, 25°C and 37°C for 30 minutes to stop the reaction. Compare the modification rate and determine the modification condition. The results showed that the PEG-modified defibrase could be obtained at these temperatures, and the modification rate was the highest at 25°C.

[0063] Choice of reaction time: Take 2ml of 0.8mg / ml defibrase solution, add 2ml of phosphate buffer to make the pH of the solution 6.5, then add 8.0mg of mPEG-SPA-20000 solid, dissolve, mix well, and take 0.3 for each ml was placed in four stoppered test tubes, an...

Embodiment 2

[0068] Isolation, Purification and Identification of PEG Modified Defibrase

[0069] Take 2ml of 1.1mg / ml defibrase solution, add about 5ml of phosphate buffer to make the pH of the solution 6.5, then add 12.2mg of mPEG-SPA-20000 solid, dissolve, mix well, and react at 25°C for 30min. The reaction was terminated by adding 3 g of glycine solid.

[0070] The above reaction solution was taken, dialyzed against 0.05 mol / L Tris-HCl buffer solution with pH 7.8, concentrated to 5 ml with an ultrafiltration membrane with a molecular weight cut-off of 10,000, and separated on a column. The chromatographic conditions are as follows:

[0071] Chromatography medium: SOURCE 30Q

[0072] Column volume: 5ml

[0073] Flow rate: 1.0ml / min

[0074]Column equilibration: equilibrate 5 times column volume with 0.05mol / L, pH 7.8 Tris-HCl (starting buffer)

[0075] Sample volume: 5ml

[0076] Elution: First use 3 times the column volume of starting buffer to elute the unadsorbed part, and then...

Embodiment 3

[0089] Isolation, Purification and Identification of Polyethylene Glycol Modified Ancholozyme

[0090] Take 2ml of 0.8mg / ml Ankelo enzyme solution, add about 5ml of phosphate buffer to make the pH of the solution 6.5, then add 9.1mg of mPEG-SPA-20000 solid, dissolve, mix well, and react at 25°C After 30 min, 3 g of glycine solid was added to terminate the reaction.

[0091] The above reaction solution was taken, dialyzed against 0.05mol / L, pH 8.3 Tris-HCl buffer solution, concentrated to 5ml with an ultrafiltration membrane with a molecular weight cut-off of 10000, and separated on a column. The chromatographic conditions are as follows:

[0092] Chromatography medium: SOURCE 30Q

[0093] Column volume: 5ml

[0094] Flow rate: 1.0ml / min

[0095] Column equilibration: Equilibrate 5 times column volume with 0.05mol / L, pH 8.3 Tris-HCl (starting buffer)

[0096] Sample volume: 5ml

[0097] Elution: First use 3 times the column volume of starting buffer to elute the unadsorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com