Method for decreasing sewage sludge from town and changing it to resources

A technology for urban sewage and recycling, applied in the field of urban sewage sludge reduction and recycling, can solve the problems of limited sludge mixing, low resource utilization rate, large loss on ignition, etc., and achieve a clear environmental Benefit, obvious reduction effect, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

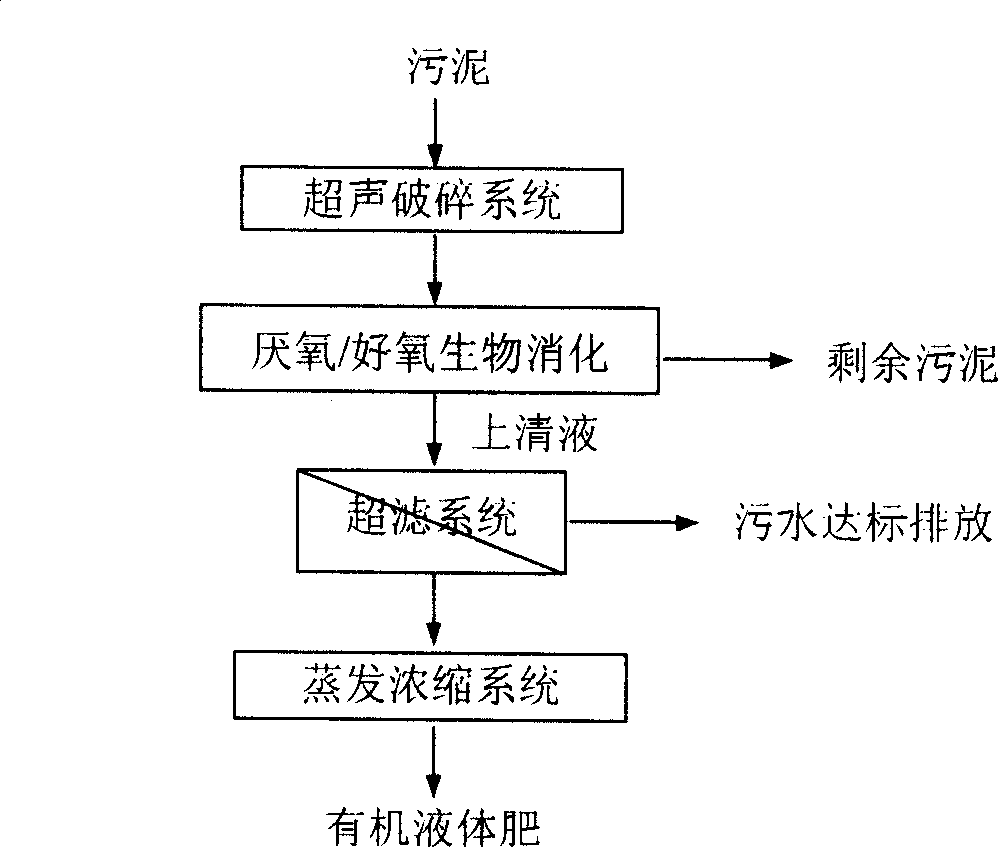

Image

Examples

Embodiment 1

[0020] The mixed sludge produced by an urban sewage treatment plant has a water content of 97.1%, a pH of 6.86, a TOC of 467.25mg / L, a conductivity of 2.05, a TS of 28.71g / L, and a suspended solids of SS of 28.26g / L , VSS is 17.79g / L.

[0021] Use 40KHz ultrasonic treatment, the power is 20W, the temperature is controlled at 80°C, and the ultrasonic action time is 10min. The sludge sludge after ultrasonic treatment first enters the anaerobic digestion system, and the additional carbon source for reverse digestion is added according to the ratio of CODcr: nitrogen: phosphorus = 200:5:1. The temperature of the control system is 33 ° C, and the hydraulic retention time is 24 hours. Biogas production 120-160mLCH 4 / gCOD. Then enter the aerobic digestion system, the dissolved oxygen (DO) is greater than 5mg / L, and the hydraulic retention time is 24 hours. The removal rate of VSS was 51.2%. After the biologically digested sludge is centrifuged, the supernatant is taken into the ...

Embodiment 2

[0023] The excess sludge produced by an urban sewage treatment plant has a water content of 96.7%, a pH of 6.65, a TOC of 681.61mg / L, a conductivity of 1.9, a TS of 34.15g / L, and a suspended solids of SS of 32.08g / L , VSS is 17.56g / L.

[0024]Use 60KHz ultrasonic treatment, the power is 40W, the temperature is controlled at 20°C, and the ultrasonic action time is 10min. The sludge slurry after ultrasonic treatment first enters the anaerobic digestion system, and the additional carbon source for reverse digestion is added according to the ratio of CODcr: nitrogen: phosphorus = 180:6:1. The temperature of the control system is 36 °C, and the hydraulic retention time is 24 hours. Biogas production 180-210mLCH 4 / gCOD. Then enter the aerobic digestion system, the dissolved oxygen (DO) is greater than 5mg / L, and the hydraulic retention time is 24 hours. The removal rate of VSS was 53.8%. After the biologically digested sludge is centrifuged, the supernatant is taken into the na...

Embodiment 3

[0026] The mixed sludge produced by an urban sewage treatment plant has a water content of 97.1%, a pH of 6.86, a TOC of 467.25mg / L, a conductivity of 2.05, a TS of 28.71g / L, and a suspended solids of SS of 28.26g / L , VSS is 17.79g / L.

[0027] Use 50KHz ultrasonic treatment, the power is 40W, the temperature is controlled at 70°C, and the ultrasonic action time is 20min. The sludge after ultrasonic treatment first enters the anaerobic digestion system, and the additional carbon source for reverse digestion is added according to the ratio of CODcr: nitrogen: phosphorus = 140:7:1. The temperature of the control system is 32 ° C, and the hydraulic retention time is 24 hours. Biogas production 140-180mLCH 4 / gCOD. Then enter the aerobic digestion system, the dissolved oxygen (DO) is greater than 5mg / L, and the hydraulic retention time is 24 hours. The removal rate of VSS was 52.6%. After the biologically digested sludge is centrifuged, the supernatant is taken into the nanofil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com