Photosensitive resin composition, cushion for display panel and display panel

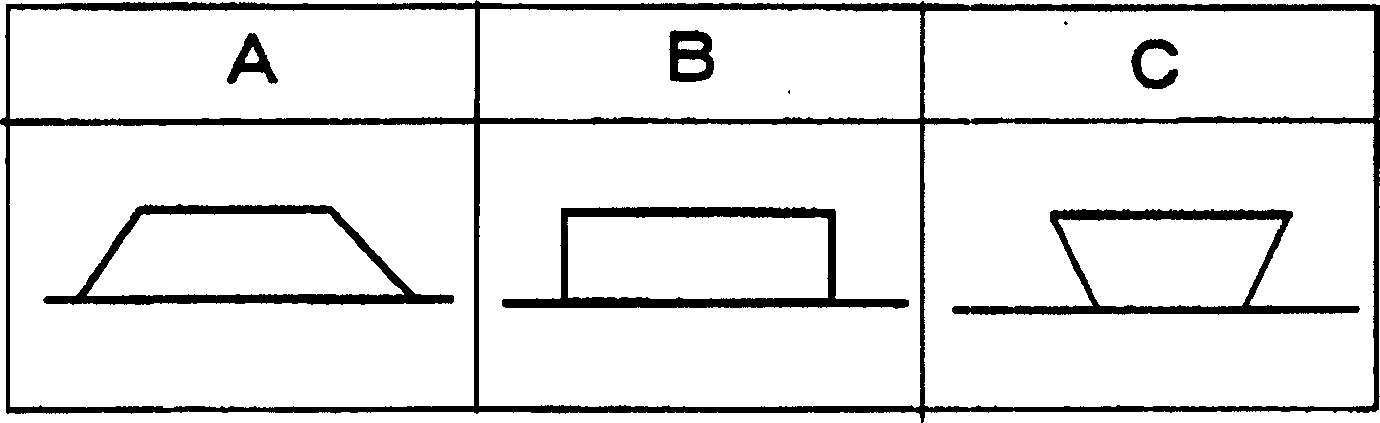

A technology of photosensitive resin and liquid crystal display panel, which is applied in the field of photosensitive resin composition, and can solve problems such as difficulty in obtaining spacer shape and film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

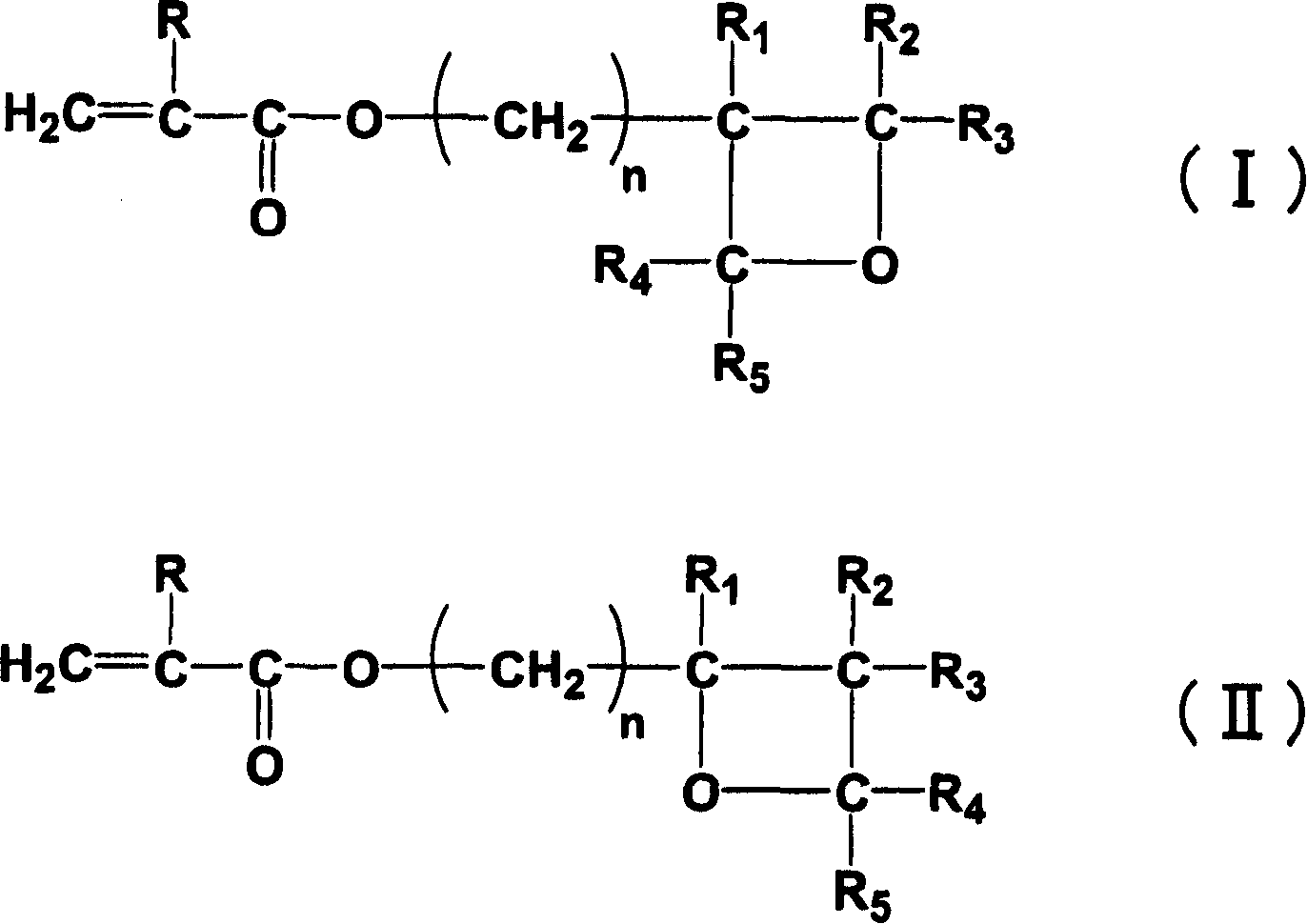

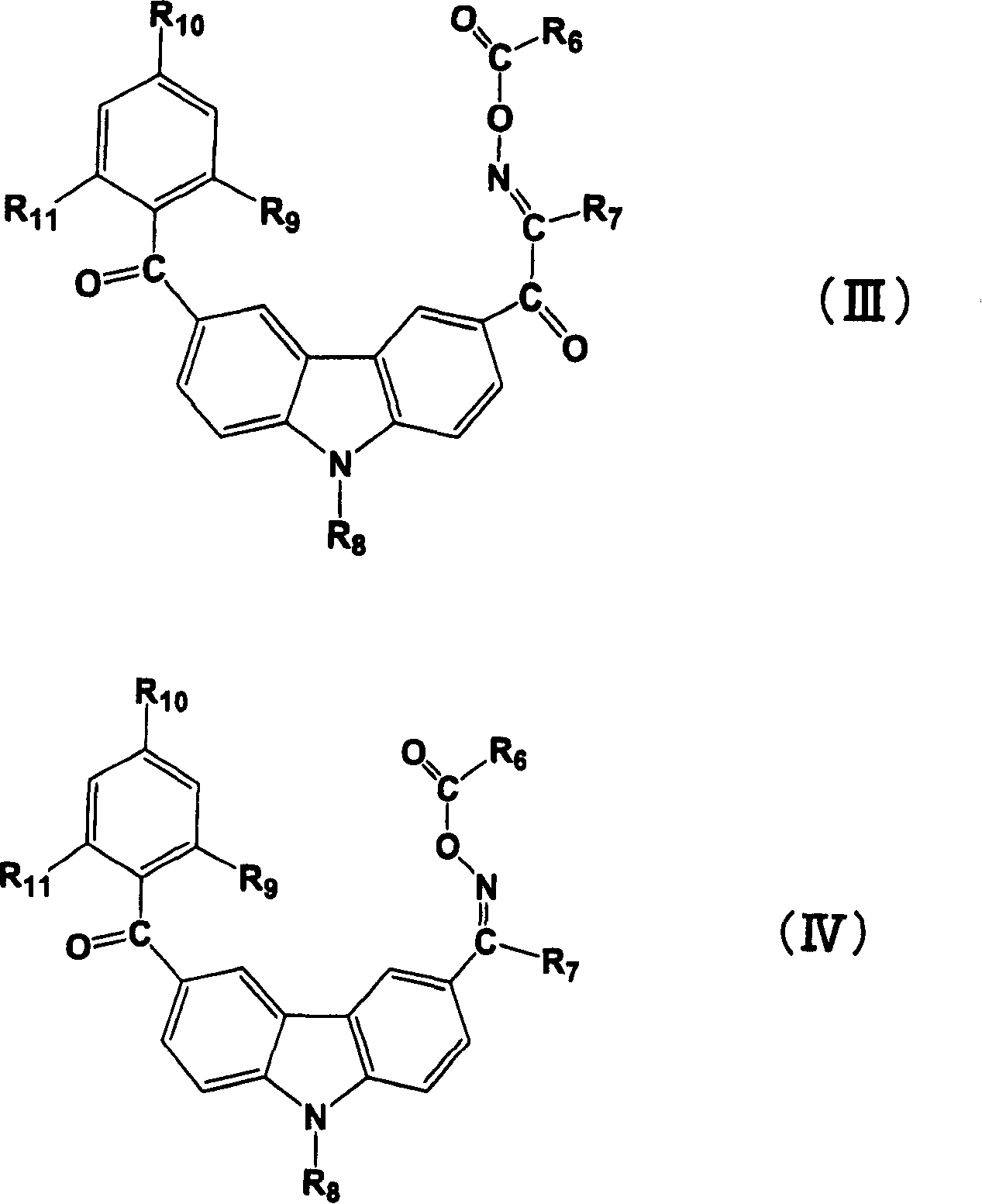

Method used

Image

Examples

Embodiment

[0165] Examples and comparative examples are shown below to explain the present invention more specifically, but the present invention is not limited to these examples.

Synthetic example 1

[0167] In a flask equipped with a cooling tube and a stirrer, 7 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile) and 200 parts by weight of propylene glycol monomethyl ether acetate were added. Then add 20 parts by weight of styrene, 16 parts by weight of methacrylic acid, and 18 parts by weight of methacrylic acid tricyclic [5.2.1.0 2,6] Decane-8-yl ester and 40 parts by weight of 3-(methacryloyloxymethyl)-3-ethyloxetane were replaced with nitrogen, and then slowly stirred. The temperature of the solution was raised to 70°C, and the temperature was maintained for 5 hours to obtain a polymer solution containing copolymer [A-1]. The solid content concentration of the obtained polymer solution was 33.0% by weight, and the weight average molecular weight of the polymer was 24,000 (the weight average molecular weight was measured using GPC (gel permeation chromatography) HLC-8020 (manufactured by Toray)), and polystyrene was used. Molecular weight converted to ethylene).

Synthetic example 2

[0169] In a flask equipped with a cooling tube and a stirrer, 7 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile) and 200 parts by weight of propylene glycol monomethyl ether acetate were added. Then add 20 parts by weight of styrene, 16 parts by weight of methacrylic acid, and 18 parts by weight of methacrylic acid tricyclic [5.2.1.0 2,6 ] Decane-8-yl ester and 40 parts by weight of 3-(methacryloxymethyl)-2-trifluoromethyloxetane were replaced with nitrogen, and then slowly stirred. The temperature of the solution was raised to 70°C, and the temperature was maintained for 5 hours to obtain a polymer solution containing a copolymer [A-2]. The solid content concentration of the obtained polymer solution was 33.0% by weight, and the weight average molecular weight of the polymer was 23,200 (the weight average molecular weight was measured using GPC (gel permeation chromatography) HLC-8020 (manufactured by Toray)), and polystyrene was used. Molecular weight converted to ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com