Method for preparing microcapsule by using doping porous calcium carbonate mould plates

A technology of porous calcium carbonate and microcapsules, which is applied to the preparation of microcapsule preparations and microspheres, can solve the problems of time-consuming, many steps, limited promotion and application, etc., and achieves simple and fast preparation methods, good industrialization prospects, and material sources broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

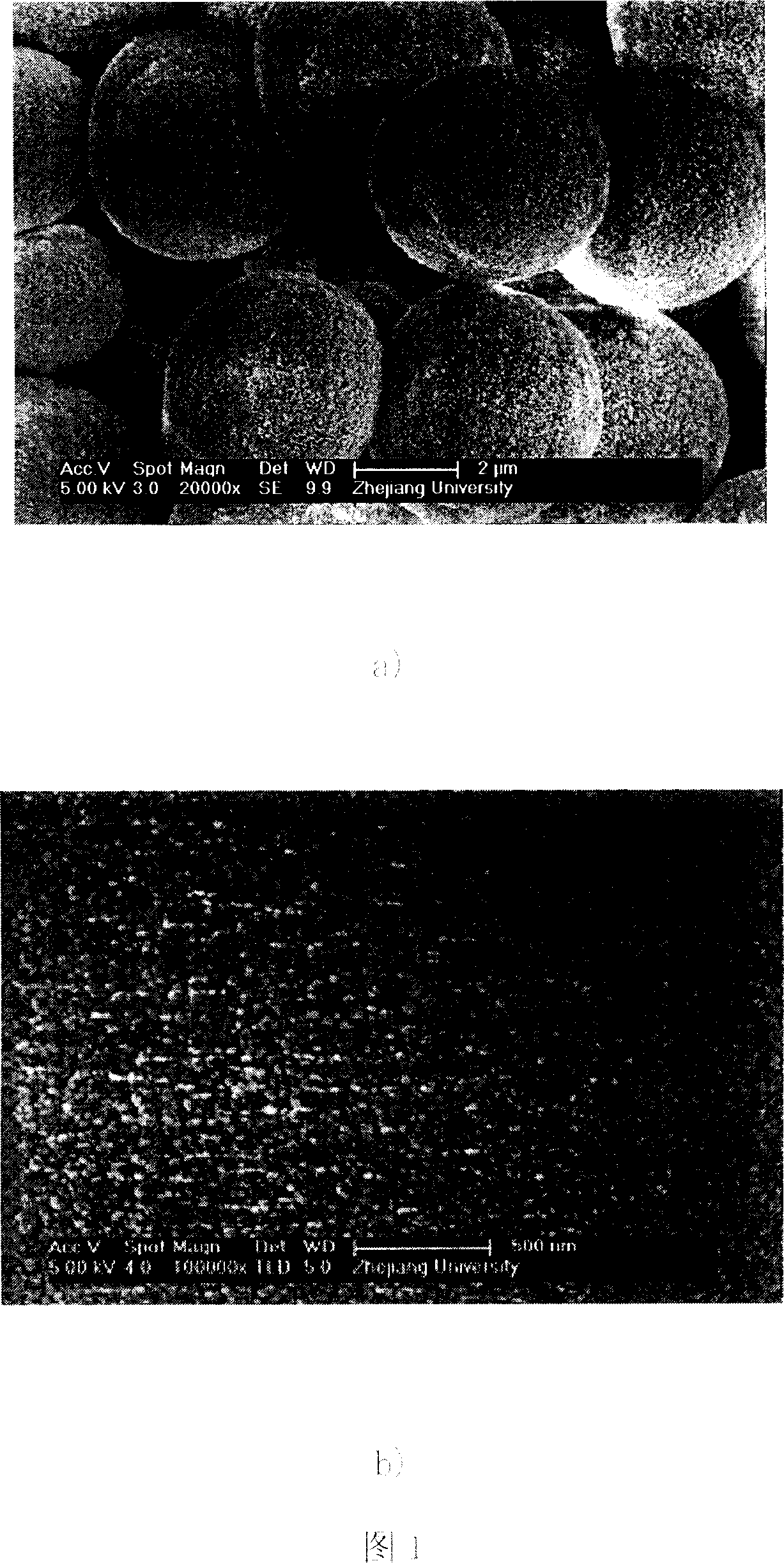

[0024] 1) Mix 100mL of calcium nitrate solution with a concentration of 0.05M and 100mg of polystyrene sodium sulfonate (PSS) (PSS / [Ca 2+ ]=2g / mol), after 10 minutes, quickly add 100mL of sodium carbonate solution with a concentration of 0.05M, and ultrasonically vibrate for 10 seconds. After standing for 1 hour, the generated calcium carbonate containing PSS (expressed as CaCO 3 (PSS)) precipitate was collected by centrifugation and washed 3 times with water. Prepared CaCO 3 (PSS) particle diameter is about 5 microns, scanning electron microscope photos are shown in Figure 1a, b.

[0025] 2) Take an appropriate amount of the above CaCO 3 (PSS) microparticles were placed in a 2 mL centrifuge tube and washed 3 times with water. In 1 M NaCl solution, add 1 mL of polyallylamine hydrochloride (PAH) solution, shake the centrifuge tube. After 10 min, wash with water 3 times to remove excess PAH, thus the CaCO 3 (PSS) surface adsorbed a layer of PAH (expressed as CaCO 3 (PSS)-...

example 2

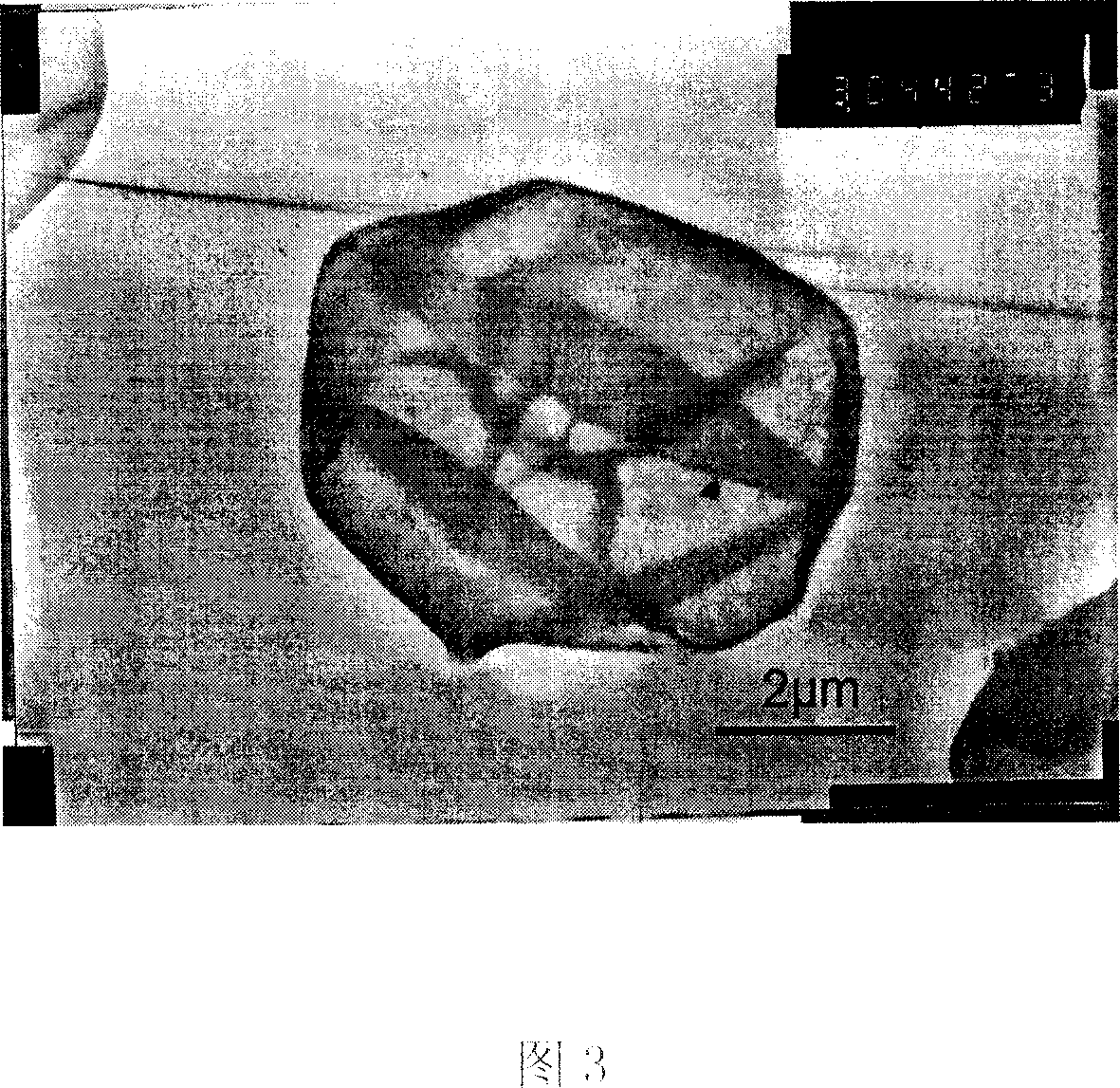

[0028] 1) prepare CaCO with the method of example 1 step 1) 3 (PSS), but the rest time is 2 minutes. Prepared CaCO 3 (PSS) particles are approximately 500 nm in diameter.

[0029] Step 2) and 3) are the same as step 2) and 3) of Example 1.

example 3

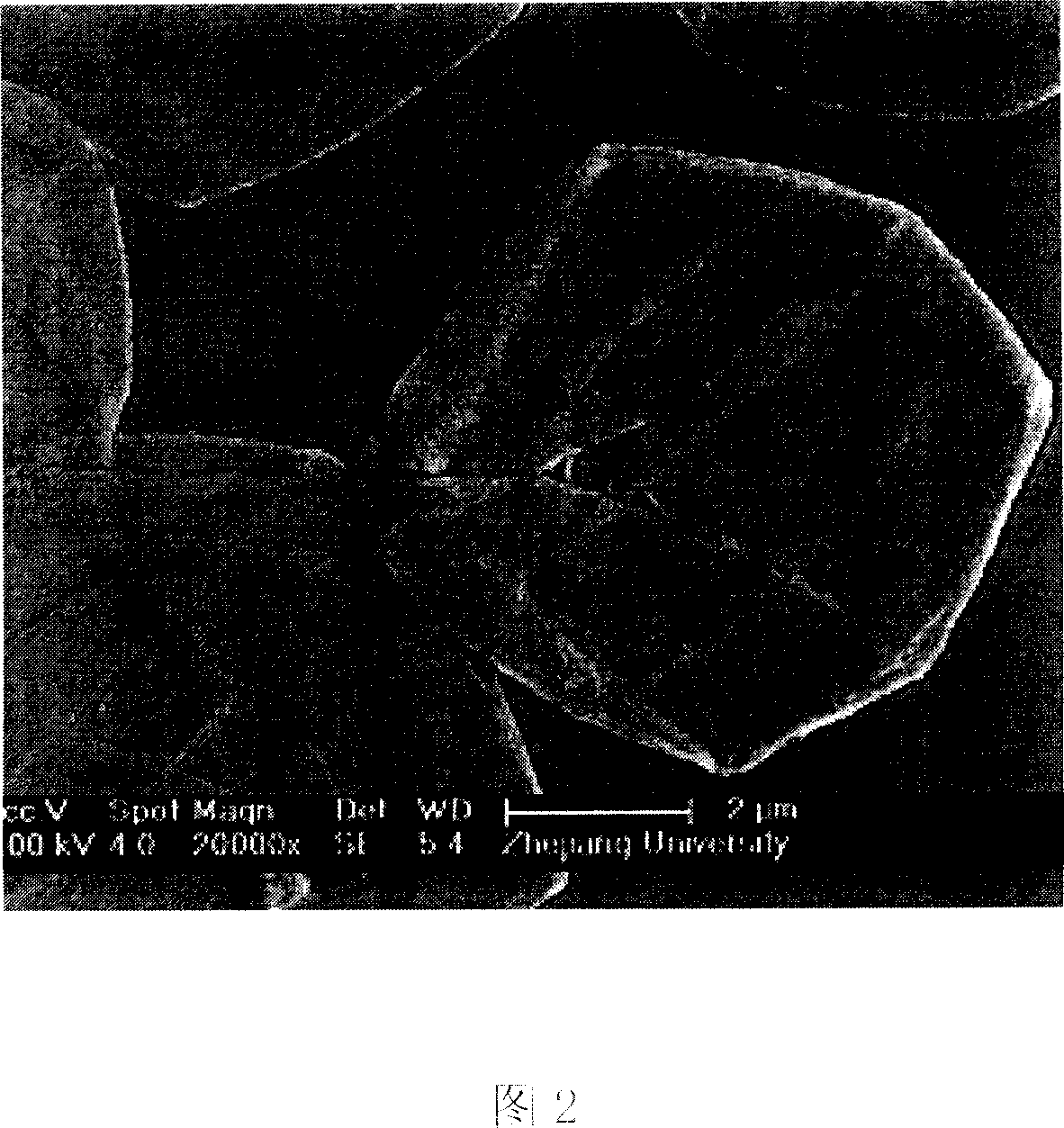

[0031] 1) prepare CaCO with the method of example 1 step 1) 3 (PSS), but the resting time is 4 hours. Prepared CaCO 3 (PSS) particles are approximately 20 microns in diameter.

[0032] Step 2) and 3) are the same as step 2) and 3) of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com