Shell composite plate and processing method thereof

A processing method and composite board technology, applied in the field of decorative materials, can solve the problems of difficulty in making breakthroughs in fabric development and no application, and achieve the effects of low price, abundant raw materials, and good decorative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mechanically cut the pearl shells into thin slices of 25×15×1 mm, clean them and dry them for later use.

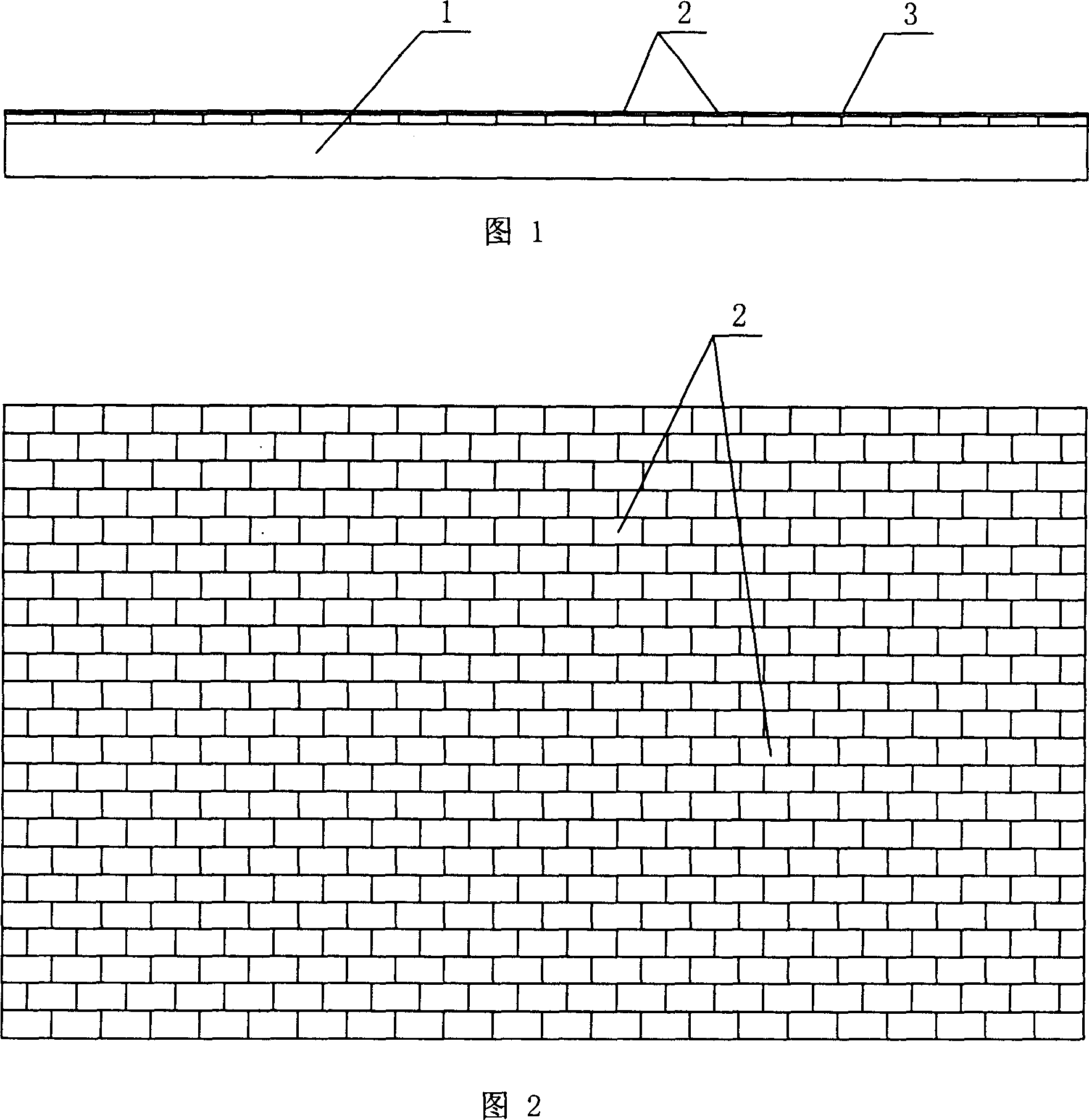

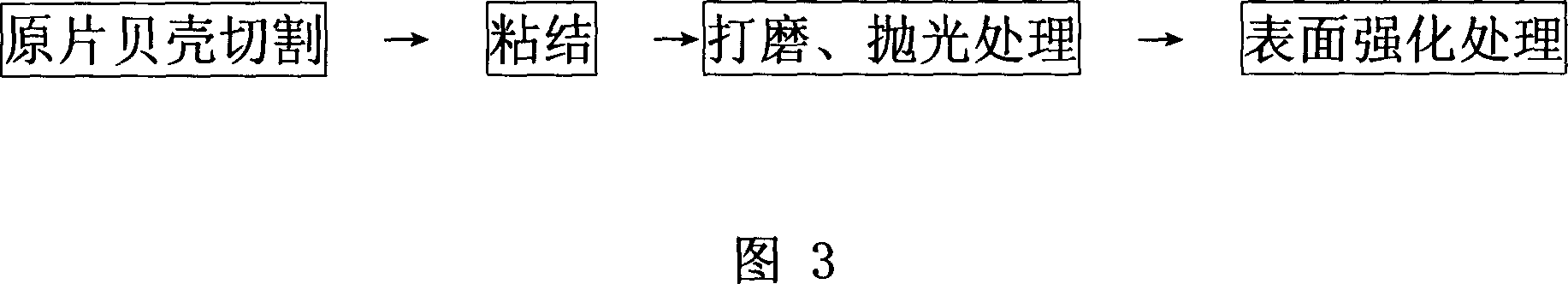

[0029] (2) Use natural marble slabs as the base material, clean the surface of the stone, use steel structure AB glue as the adhesive, first scrape a layer of adhesive on the surface of the stone, and stick the shell pieces on the surface of the stone, each row of shells The pieces are collaged in a dislocation manner, as shown in Figure 2, and the adhesive is used to fill the gaps. After the adhesive is completely dry, it is polished and polished.

[0030] (3) Grinding and polishing treatment adopts wet polishing process, using water as lubricant, grinding and polishing with plastic polishing discs of 50, 100, 200, 300, 500, 800, 1000, 2000, 3000, 6000, 10000 in sequence Process until the surface brightness of the shell reaches 40 degrees.

[0031] (4) Spraying a layer of wear-resistant nano-alumina coating on the shell surface for strengthening treatment.

Embodiment 2

[0033] (1) Mechanically cut the pearl shells into thin slices of 25×15×1 mm, clean them and dry them for later use.

[0034] (2) Use the laminate as the base material, clean the surface of the laminate, use steel structure AB glue as the adhesive, first scrape a layer of adhesive on the surface of the laminate, and stick the shell pieces on the surface of the laminate. The seashell sheets are collaged in a dislocation manner, as shown in Figure 2, and the adhesive is used to fill the gaps. After the adhesive is completely dry, it is polished and polished.

[0035] (3) Grinding and polishing treatment adopts wet polishing process, using water as lubricant, and grinding with plastic polishing discs marked with , 50, 100, 200, 300, 500, 800, 1000, 2000, 3000, 6000, 10000 , Polishing treatment, until the surface brightness of the shell reaches 40 degrees, and then use stone brightener to enhance the surface of the shell, so that the brightness of the shell surface reaches more tha...

Embodiment 3

[0037] (1) Mechanically cut the pearl shells into thin slices of 25×15×1 mm, clean them and dry them for later use.

[0038] (2) Use 9mm plywood as the base material, clean the surface of the plywood, use steel structure AB glue as the adhesive, first scrape a layer of adhesive on the surface of the plywood, and paste the shell pieces on the surface of the plywood, each row of shell pieces Collage according to the dislocation method, as shown in Figure 2, and fill the gaps with adhesive, and perform grinding and polishing after the adhesive is completely dry.

[0039] (3) Grinding and polishing treatment adopts dry throwing process, using polishing powder, using paraffin as lubricant, and using 20, 30, 50, 100, 200, 300, 500, 800, 1000, 2000, 3000, 5000 wool in turn The dish is polished and polished until the surface brightness of the shell reaches 40 degrees.

[0040] (4) Spraying a layer of wear-resistant nano-alumina coating on the shell surface for strengthening treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com