Clean production process of tetracycline antibiotics

A clean production and antibiotic technology, applied in organic chemistry, fermentation, carboxylic acid amide separation/purification, etc., can solve the problems of heavy environmental protection burden of manufacturers, inability to perform biochemical treatment, high ammonia nitrogen content, etc., and solve the pollution problem of primary crystallization mother liquor , Solve the pollution of the mother liquor, the effect of low energy consumption for concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

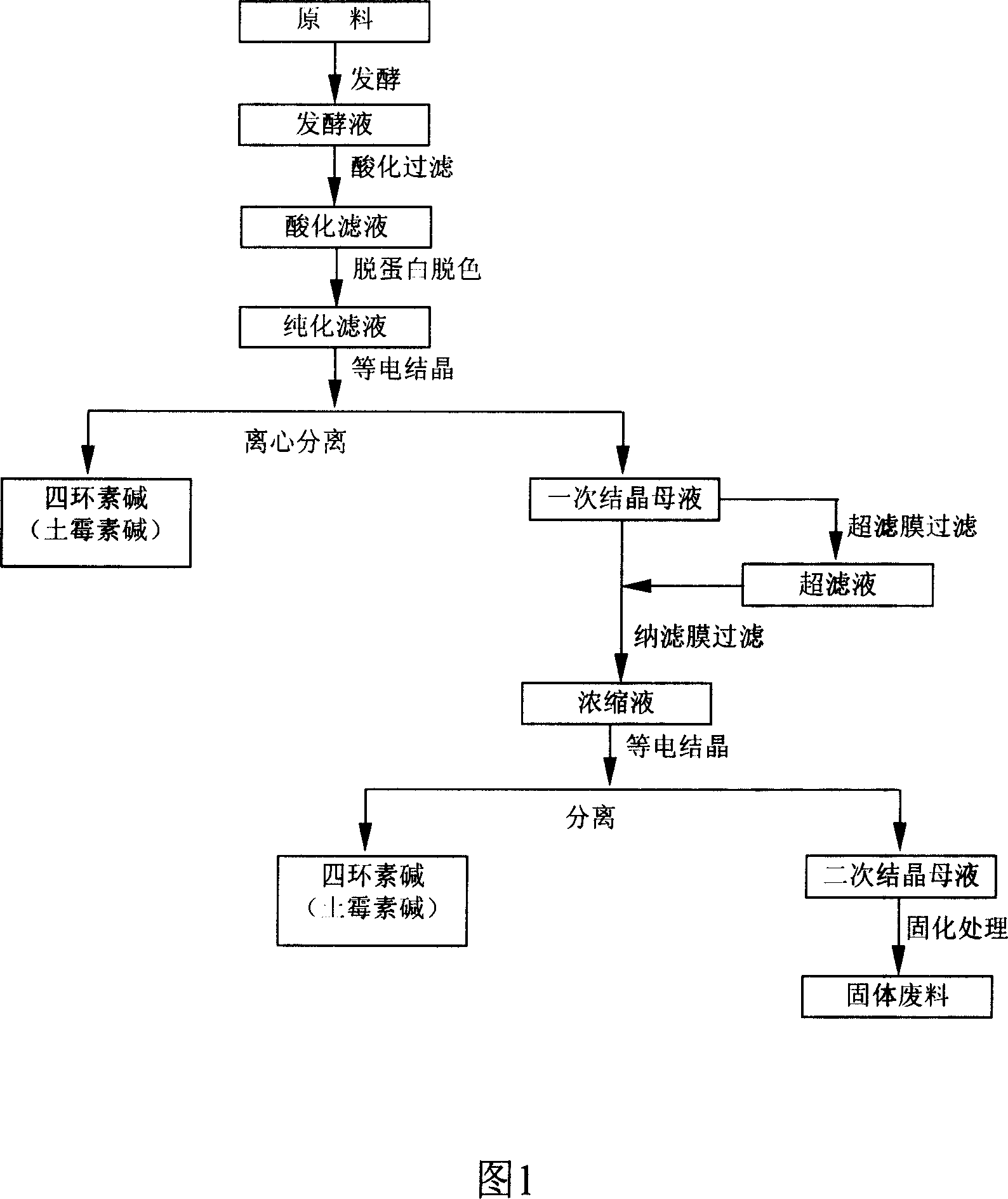

[0025] Fig. 1 is a flow chart of the clean production process of tetracyclic antibiotics of the present invention. Both tetracycline and oxytetracycline, which belong to tetracyclic antibiotics, are produced by this process. The clean production process steps of tetracyclic antibiotics of the present invention are as follows: firstly, the raw materials used for producing tetracyclic antibiotics are fermented by microorganisms to obtain fermentation broth containing secondary metabolites, acidified with 3% (w / v) oxalic acid, and mixed with plate Frame filtration to obtain the acidified filtrate (pH value is 2.0); then the acidified filtrate is adsorbed with zinc sulfate yellow blood salt or decolorized with 122 macroporous cationic resin to obtain the purified filtrate; then the purified filtrate is adjusted to pH with ammonia water or liquid ammonia The value is 4.6-4.8 to carry out isoelectric crystallization, separate after the crystallization is complete, the solid is the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com