Silicon film forming equipment

A silicon film and gas supply device technology, applied in the field of silicon film forming devices, can solve the problems of uniform laser irradiation, high manufacturing cost of crystalline silicon film, rough film surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

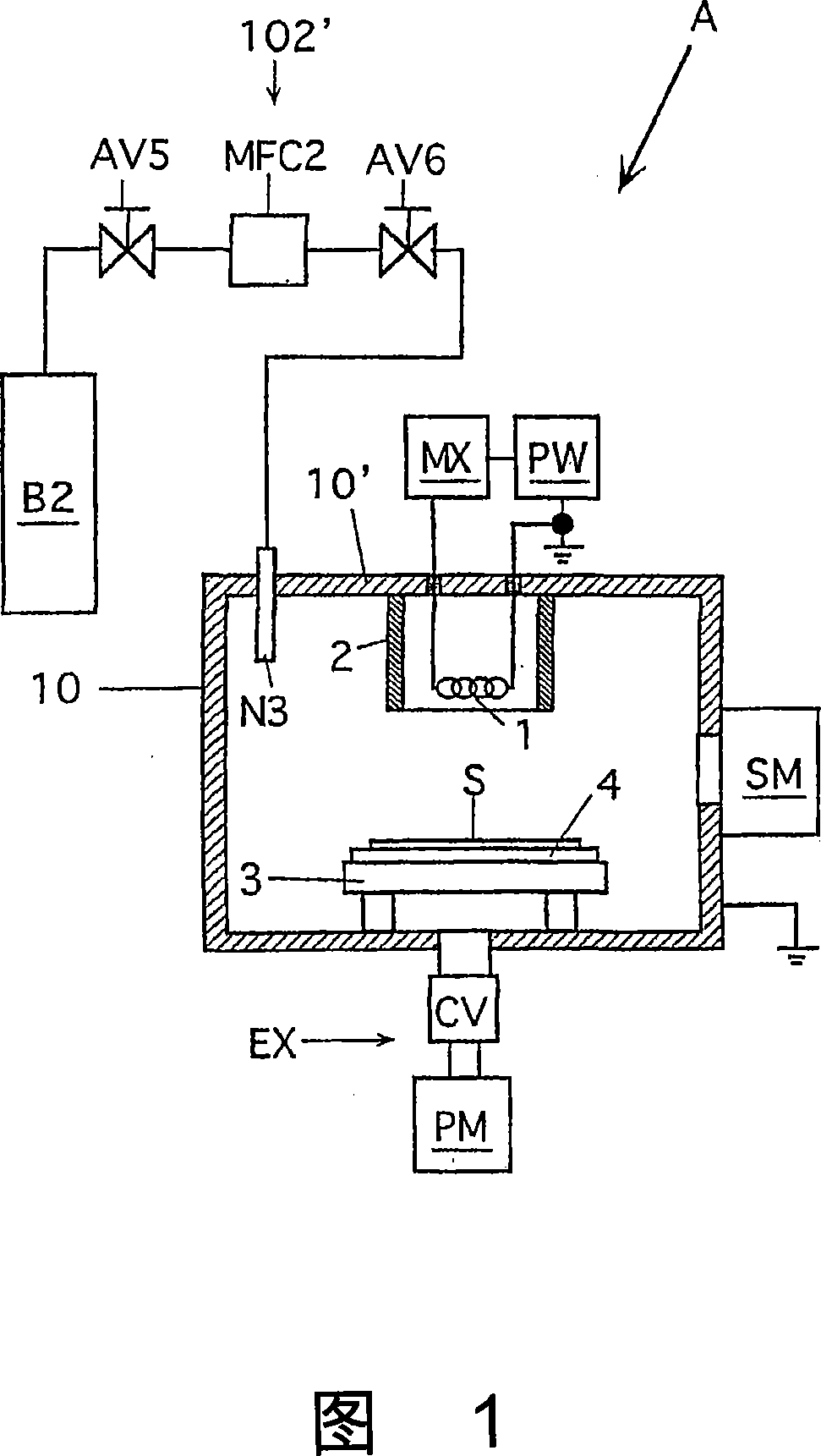

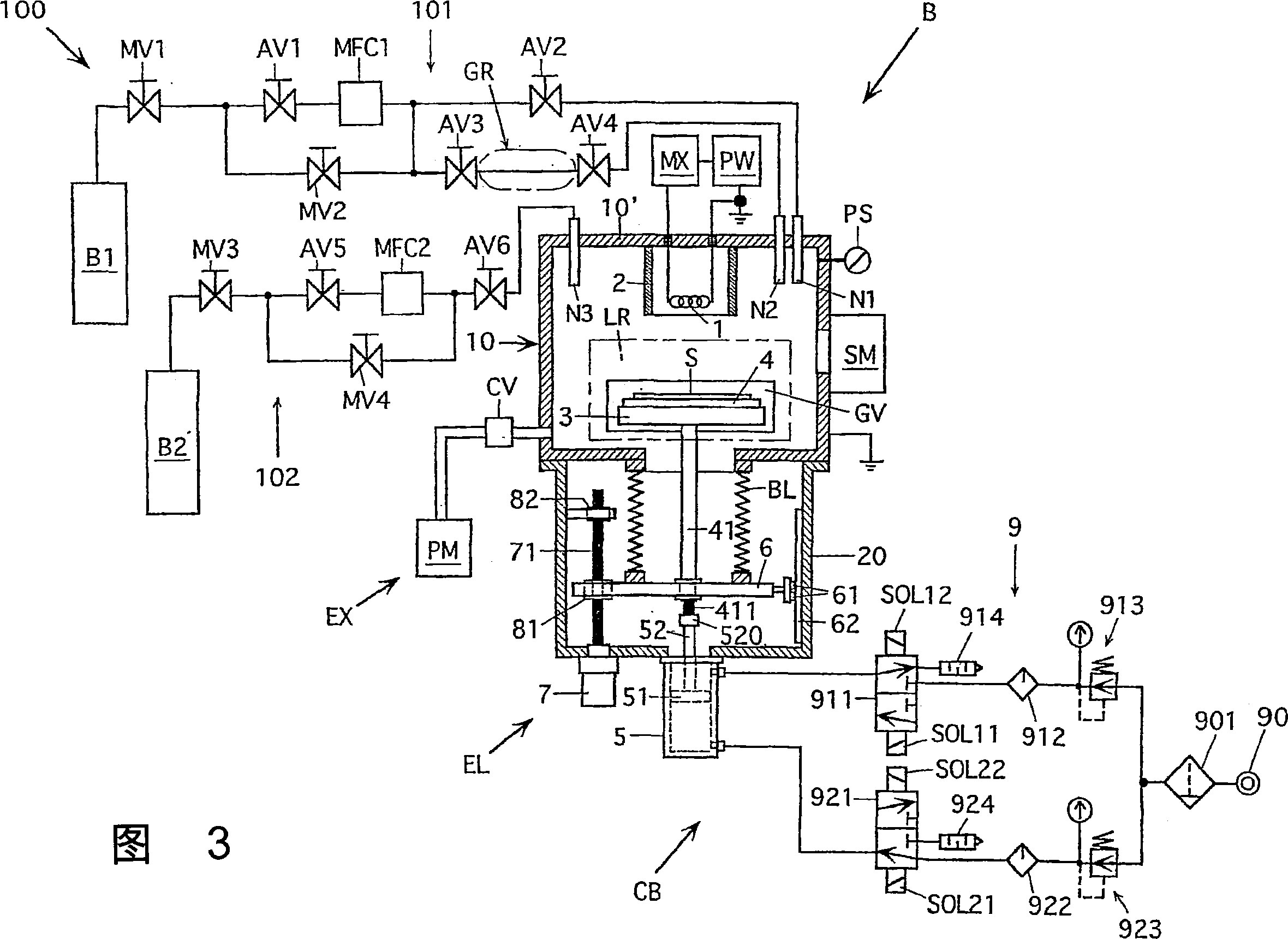

[0175] Film-forming conditions were as follows.

[0176] High frequency power: 60 MHz, 4000 watts

[0177] The silane gas (SiH 4 ) pressure and volume:

[0178] Pressure 0.07 Mbar

[0179] The amount can be selected from 100cc to 300cc, but in this embodiment it is 231cc

[0180] Silane gas supply amount of mass flow controller MFC1: 1 sccm

[0181] Mass flow controller MFC2 hydrogen supply: 150sccm

[0182] Film forming pressure: 0.67 bar (5 mTorr)

[0183] Film-forming chamber capacity: 1.5 cubic meters

[0184] Film substrate: non-alkali glass substrate

[0185] Film forming temperature: 400°C

[0186] Film thickness: 500 Angstroms

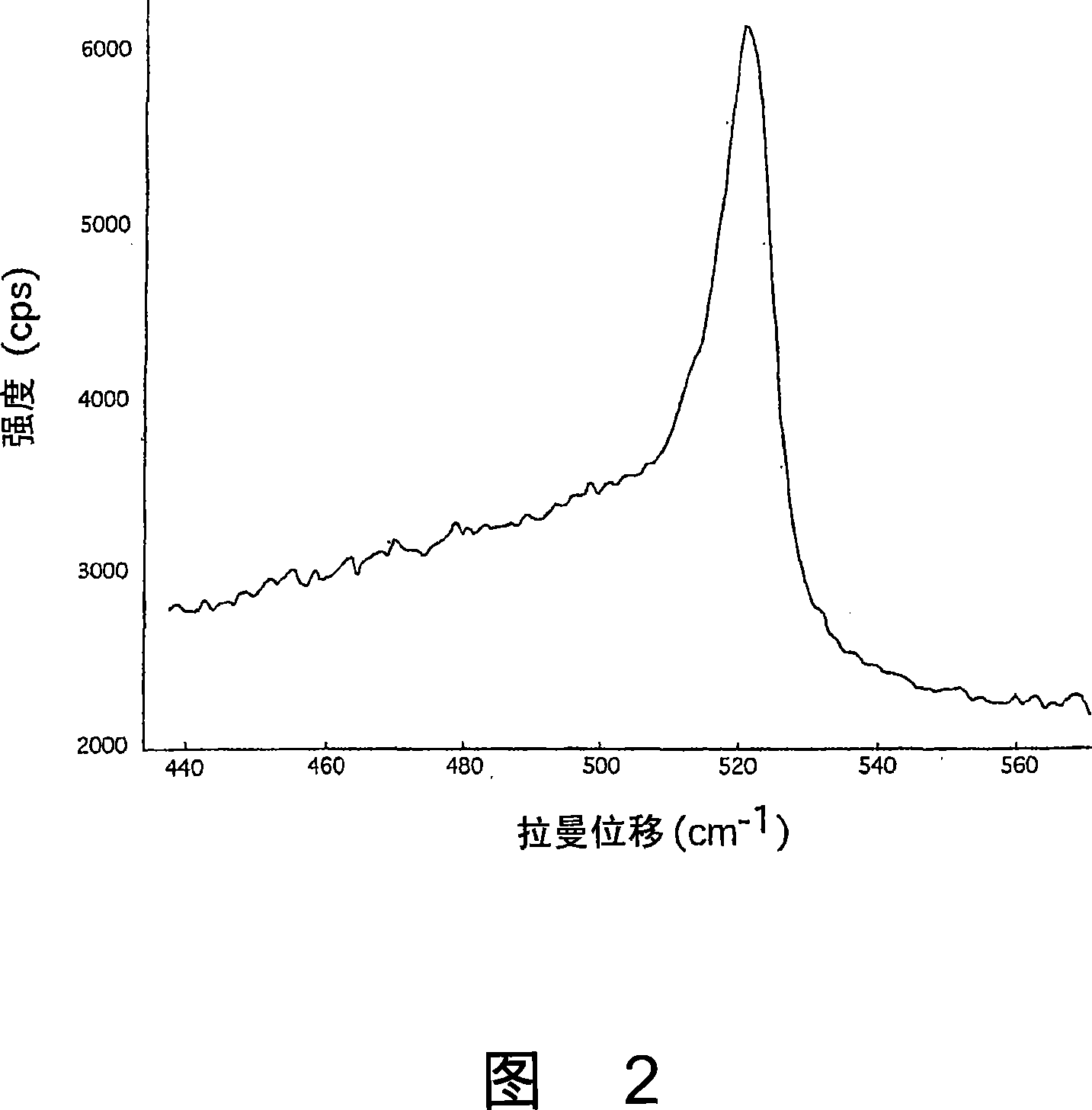

[0187] According to this condition, when a silicon film is formed on a substrate, and the UV reflective surface intensity on the substrate interface and the UV reflective surface intensity on the film surface are measured based on UV (ultraviolet) reflectance measurement, it is confirmed that the silicon film is at the film interface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com