Zirconium-base loaded vanadium-phosphor oxide catalyst, and its preparing and use

A technology of vanadium phosphorus oxide and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of low conversion rate of butane and low selectivity of maleic anhydride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

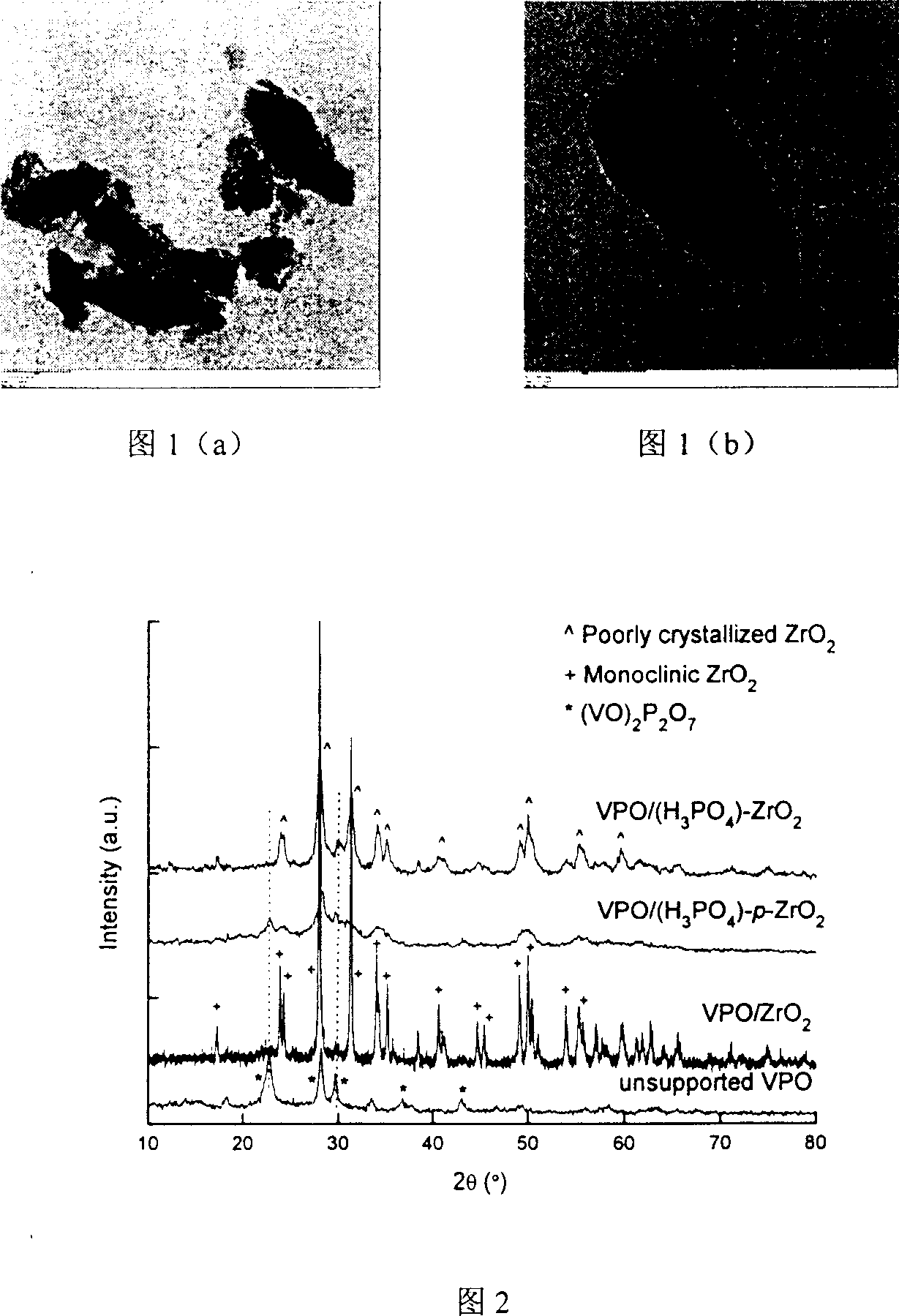

Embodiment 1

[0029] 5.00g ZrOCl 2 ·8H 2 Dissolve O and 1.00g CTAB in water, stir to obtain a clear solution, continue to stir at 70°C for 2 hours, then slowly add 2mol / L NaOH solution dropwise to the solution, and adjust the pH to ≥ 12.00 to obtain a white sol-gel . The mixture was transferred to an autoclave and kept at 100 °C for 48 h, then cooled to room temperature naturally. The solid was filtered and washed until the pH of the filtrate was neutral. The resulting white solid was then dried at 100°C. The white solid was heated from room temperature to 550° C. at a rate of 1° C. / min in the air and roasted at this temperature for 8 hours. Thus, a zirconium-based support without phosphoric acid modification was obtained.

[0030] Weigh V 2 o 5 2.4 grams, placed in the mixed solution of isobutanol / benzyl alcohol (30ml / 30ml), after refluxing at 140°C for 6 hours, add 1.1 grams of polyethylene glycol (PEG2000) with a molecular weight of 2000, and add 6.0 grams of zirconium prepared a...

Embodiment 2

[0033] 4.00g ZrOCl 2 ·8H 2 Dissolve O and 1.00g CTAB in water, stir to obtain a clear solution, continue to stir at 70°C for 2 hours, then slowly add 2mol / L NaOH solution dropwise to the solution, and adjust the pH to ≥ 12.00 to obtain a white sol-gel . The mixture was transferred to an autoclave and kept at 100 °C for 48 h, then cooled to room temperature naturally. The solid was filtered and washed until the pH of the filtrate was neutral. The resulting white solid was then dried at 100°C and placed in 1mol / L H 3 PO 4 In the solution, add H per gram of solid sample 3 PO 4 20ml of the solution was stirred at a constant temperature of 70°C for 12h, and then the treated sample was filtered and washed until the filtrate was neutral, and then dried at 100°C. In the air at a rate of 1 ° C / min from room temperature to 550 ° C and constant temperature roasting at this temperature for 8 hours. A phosphoric acid-modified zirconium-based support is thus obtained.

[0034] We...

Embodiment 3

[0037] 4.00g ZrOCl 2 ·8H 2 Dissolve O and 1.00g CTAB in water, stir to obtain a clear solution, continue to stir at 70°C for 2 hours, then slowly add 2mol / L NaOH solution dropwise to the solution, and adjust the pH to ≥ 12.00 to obtain a white sol-gel . The mixture was transferred to an autoclave and kept at 100 °C for 48 h, then cooled to room temperature naturally. The solid was filtered and washed until the pH of the filtrate was neutral. Then the obtained white solid was dried at 100° C., raised from room temperature to 550° C. in air at a rate of 1° C. / min, and roasted at this temperature for 8 hours at a constant temperature. Put the calcined solid in 1mol / L H 3 PO 4 In the solution, add H per gram of solid sample 3 PO 4 20ml of the solution was stirred at 70°C for 12 hours, then the sample was filtered and washed until the filtrate was neutral, dried at 100°C, and then roasted under the same conditions as above to obtain a phosphoric acid-modified zirconium-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com