Stable elaioplast compositions

A liposome composition and liposome technology are applied in the direction of liposome delivery, drug combination, active ingredients of heavy metal compounds, etc., which can solve problems such as hypersensitivity and expensive phospholipids, so as to improve tolerance and reduce systemic Toxicity, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 paclitaxel liposome

[0034] prescription:

[0035] Paclitaxel 0.15g

[0036] Hydrogenated Soy Lecithin 4g

[0037] Cholesterol 0.6g

[0038] Vitamin E 25mg

[0039] Sucrose 12g

[0040] Water for injection 120ml

[0041] Weigh the prescribed amount of paclitaxel, hydrogenated soybean lecithin, cholesterol, and vitamin E and add 100ml of absolute ethanol, after dissolving, drain the solvent with a rotary evaporator in the presence of nitrogen, prepare a film, and place it in a vacuum desiccator overnight , to remove residual solvent. Add sucrose solution dissolved in water for injection, 55°C water bath, magnetically stir for 1 hour, ultrasonically disperse, homogenize with a high-pressure homogenizer, filter aseptically with a 0.22-micron PVDF membrane, divide into vials, and freeze-dry. Ventilate the vial with nitrogen, and seal it with a gland.

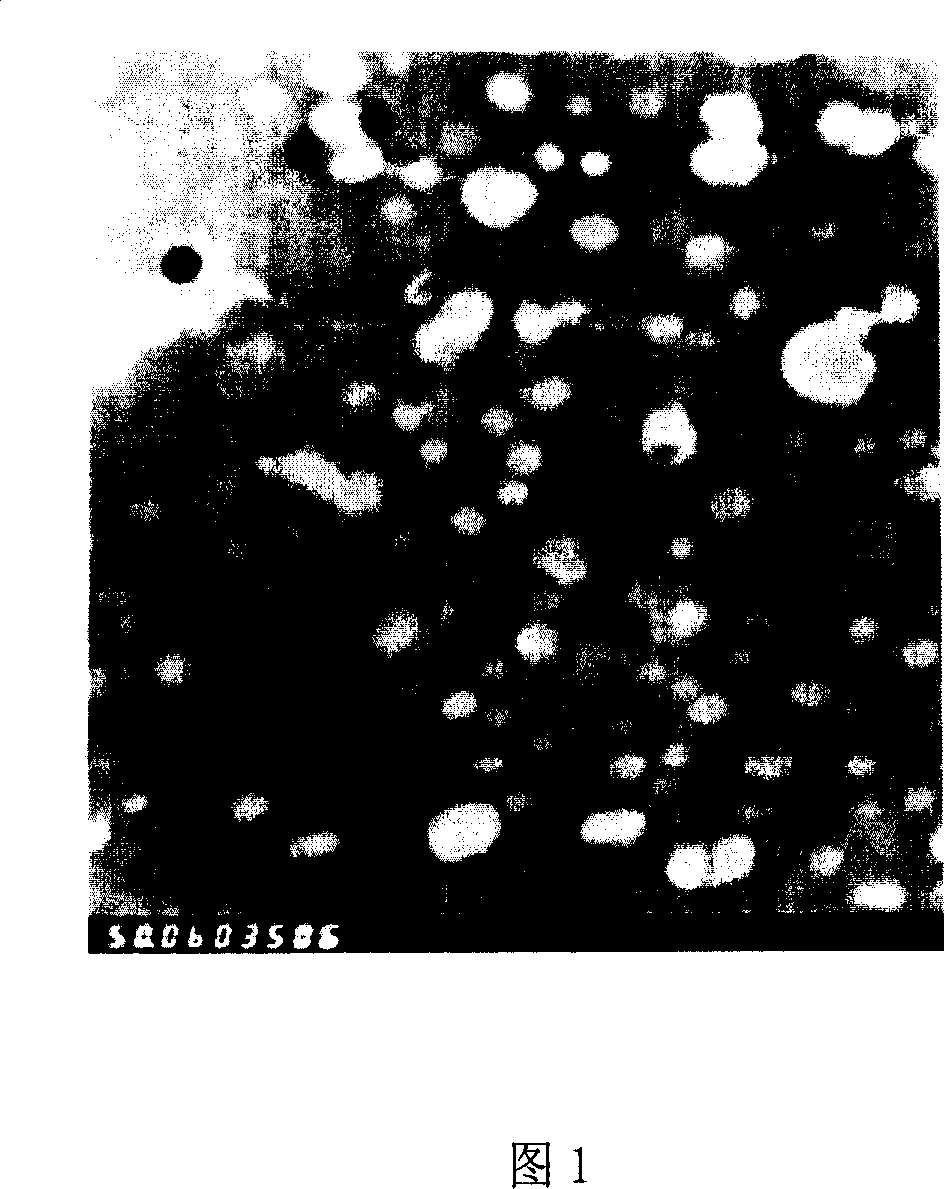

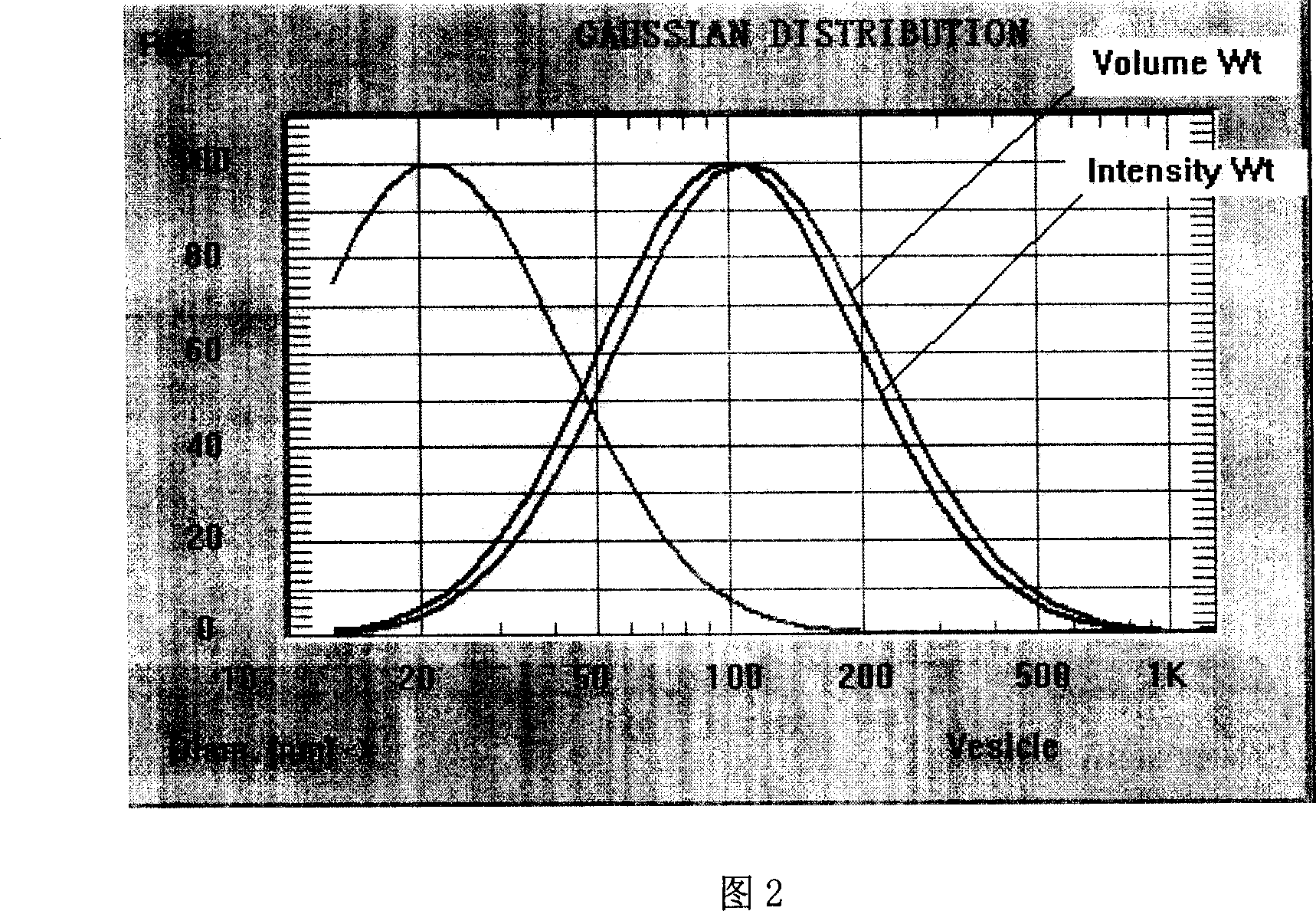

[0042] The electron micrograph of the liposome made is shown in Fig. 1 (magnificat...

Embodiment 2

[0045] The preparation of embodiment 2 paclitaxel liposomes

[0046] prescription:

[0047] Paclitaxel 0.15g

[0048] Hydrogenated Lecithin 4g

[0049] Cholesterol 1g

[0050] Vitamin E 20mg

[0051] Sucrose 15g

[0052] Water for injection 150ml

[0053] Weigh the prescribed amount of paclitaxel, hydrogenated soybean lecithin, cholesterol, and vitamin E, add 100ml of absolute ethanol, dissolve, prepare a film with a rotary evaporator, and place it in a vacuum desiccator overnight to remove the residual solvent. Add sucrose solution dissolved in water for injection, 58 ° C water bath, magnetic stirring for 1 hour, ultrasonic dispersion, sequentially use 0.8, 0.4, 0.2 micron polycarbonate film, extrude with extruder under high pressure, divide into vials, freeze dry , gland seal.

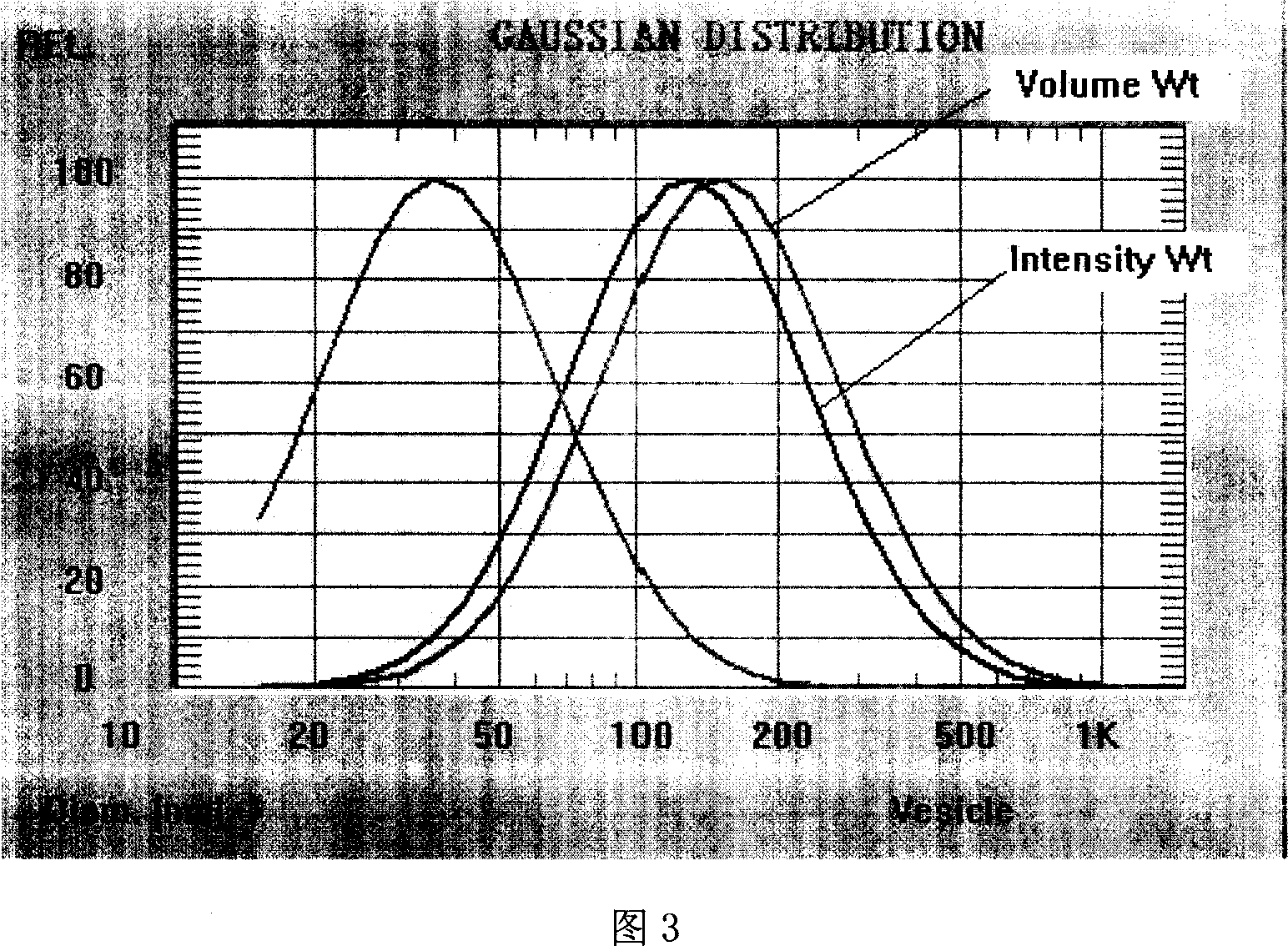

[0054] Measured in the same manner as in Example 1, the average particle diameter of the sample before freeze-drying was 164.6 nm, and the encapsulation efficiency was 92.1%.

Embodiment 3

[0055] The preparation of embodiment 3 paclitaxel liposomes

[0056] prescription:

[0057] Paclitaxel 0.15g

[0058] Hydrogenated soybean lecithin 3.5g

[0059] Cholesterol 1.5g

[0060] Vitamin E 16mg

[0061] Sucrose 5g

[0062] Water for injection 50ml

[0063] Weigh the prescribed amount of paclitaxel, hydrogenated soybean lecithin, cholesterol, and vitamin E, add 100ml of absolute ethanol, dissolve, prepare a film with a rotary evaporator, and place it in a vacuum desiccator overnight to remove the residual solvent. Add sucrose solution dissolved in water for injection, 60°C water bath, magnetically stir for 1 hour, ultrasonically disperse, homogenize with a high-pressure homogenizer, extrude with a 0.2-micron polycarbonate membrane, filter aseptically with a 0.22-micron PVDF membrane, and dispense into Vials, freeze-dried, sealed with a gland.

[0064] Measured in the same manner as in Example 1, the average particle diameter of the sample before freeze-drying wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com