Work-cold joint supplied cross still state straight and reverse coupling heating power circulation system and method

A thermodynamic cycle system and co-supply technology, applied in the field of energy, can solve the problems of high exhaust temperature of heat source, increase irreversible loss in the condensation process of power cycle, waste of pressure energy, etc., to increase the concentration of mixed working medium and improve temperature matching situation, the effect of improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

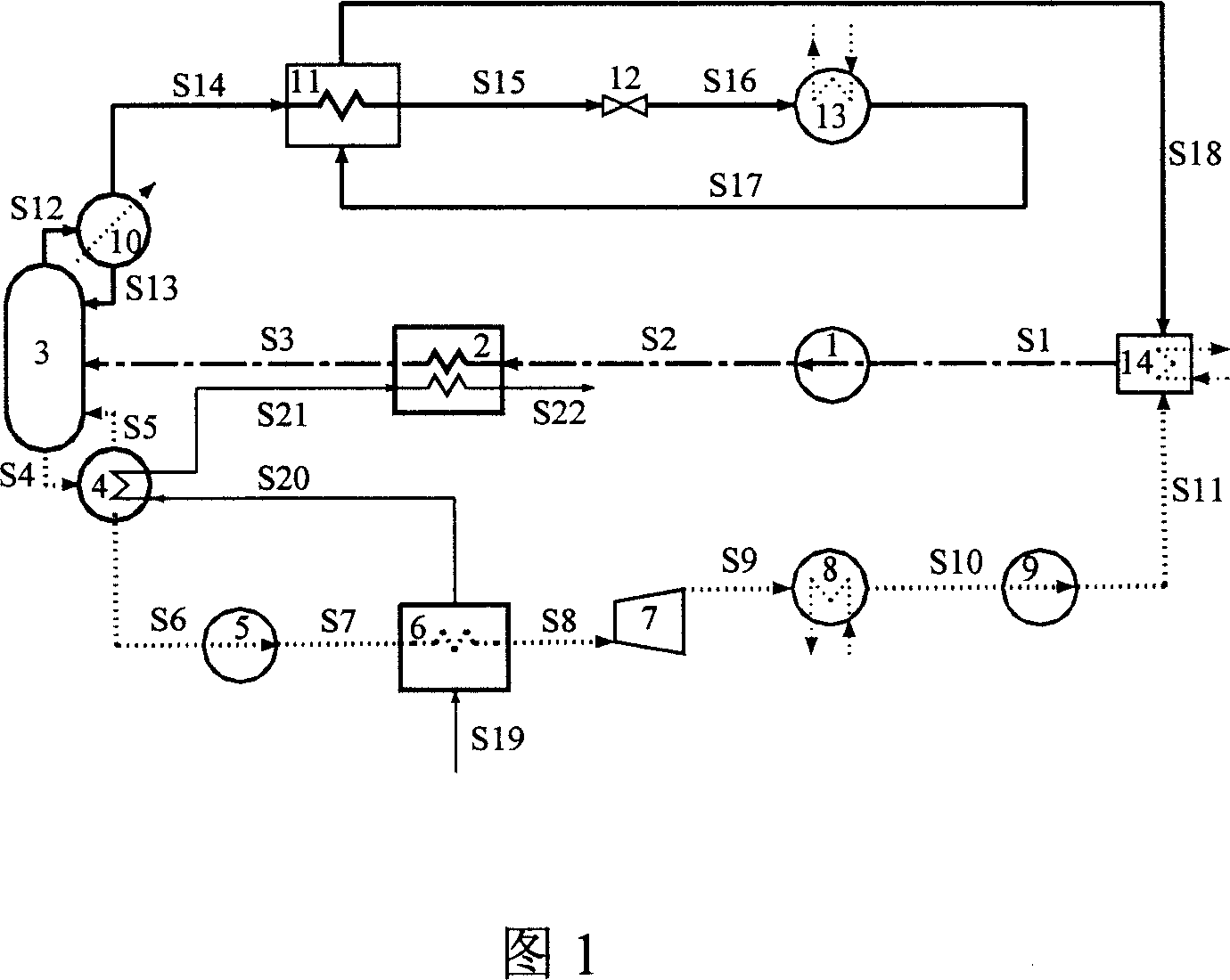

[0044] The present embodiment system consists of pumps 1, 5, 9, heat exchanger 2, rectification tower 3 (including tower bottom reboiler 4 and tower top condenser 10), waste heat boiler 6, steam turbine 7, condenser 8, Cooler 11, throttle valve 12, evaporator 13, and absorber 14. The specific process is:

[0045] In the refrigeration reverse cycle, the basic concentration of ammonia water working medium S1 is boosted by pump 1, and heat exchanger 2 is heated to saturated liquid S3 and sent to rectification tower 3 to split into dilute ammonia solution S4 and concentrated ammonia vapor S12.

[0046] After the concentrated ammonia vapor S12 is completely condensed by the tower top condenser 10, S13 is refluxed in the rectification tower, and S14 is used as a refrigerant solution to obtain a low-temperature concentrated ammonia solution S16 after being supercooled by the cooler 11 and throttling and reducing pressure by the throttle valve 12. Then it is sent to the evaporator 13...

Embodiment 2

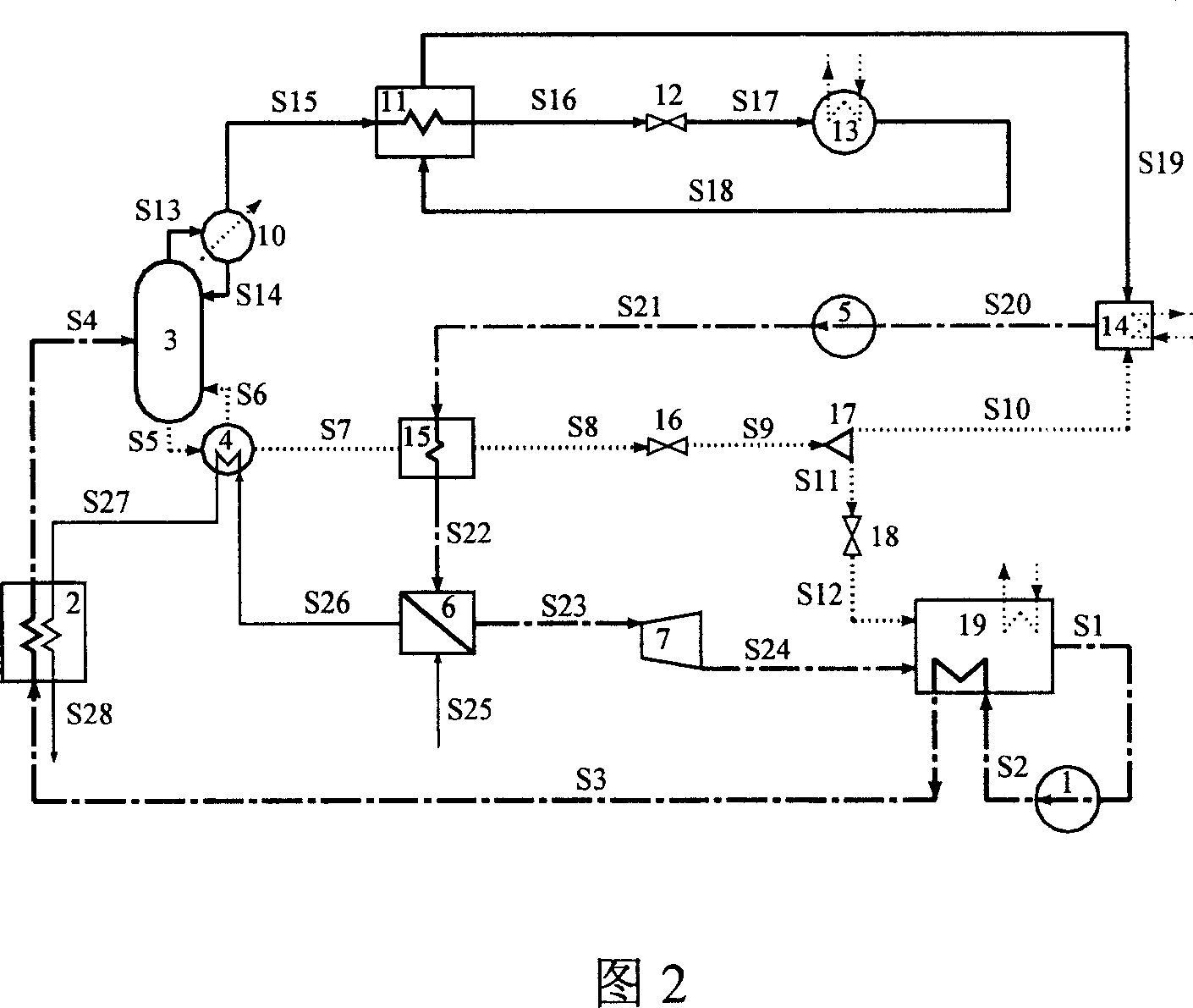

[0050] The system of this embodiment consists of pumps 1, 5, heat exchangers 2, 15, rectification tower 3 (including tower bottom reboiler 4 and tower top condenser 10), waste heat boiler 6, steam turbine 7, cooler 11, Throttle valves 12, 16, 18, evaporator 13, high-pressure absorber 14, flow splitter 17, and low-pressure absorber 19 form. The specific process is:

[0051] In the refrigeration reverse cycle, after the basic concentration ammonia water working medium S1 is boosted by pump 1, it absorbs heat through low-pressure absorber 19 and heat exchanger 2 to saturated liquid S4, and then sends it to rectification tower 3 to split into dilute ammonia solution S5 and concentrated ammonia solution S5. Ammonia vapor S13.

[0052] The concentrated ammonia vapor S13 is completely condensed by the tower top condenser 10, part of the concentrated ammonia liquid S14 is refluxed in the rectification tower, and the rest of the concentrated ammonia liquid S15 is used as a refrigerant...

Embodiment 3

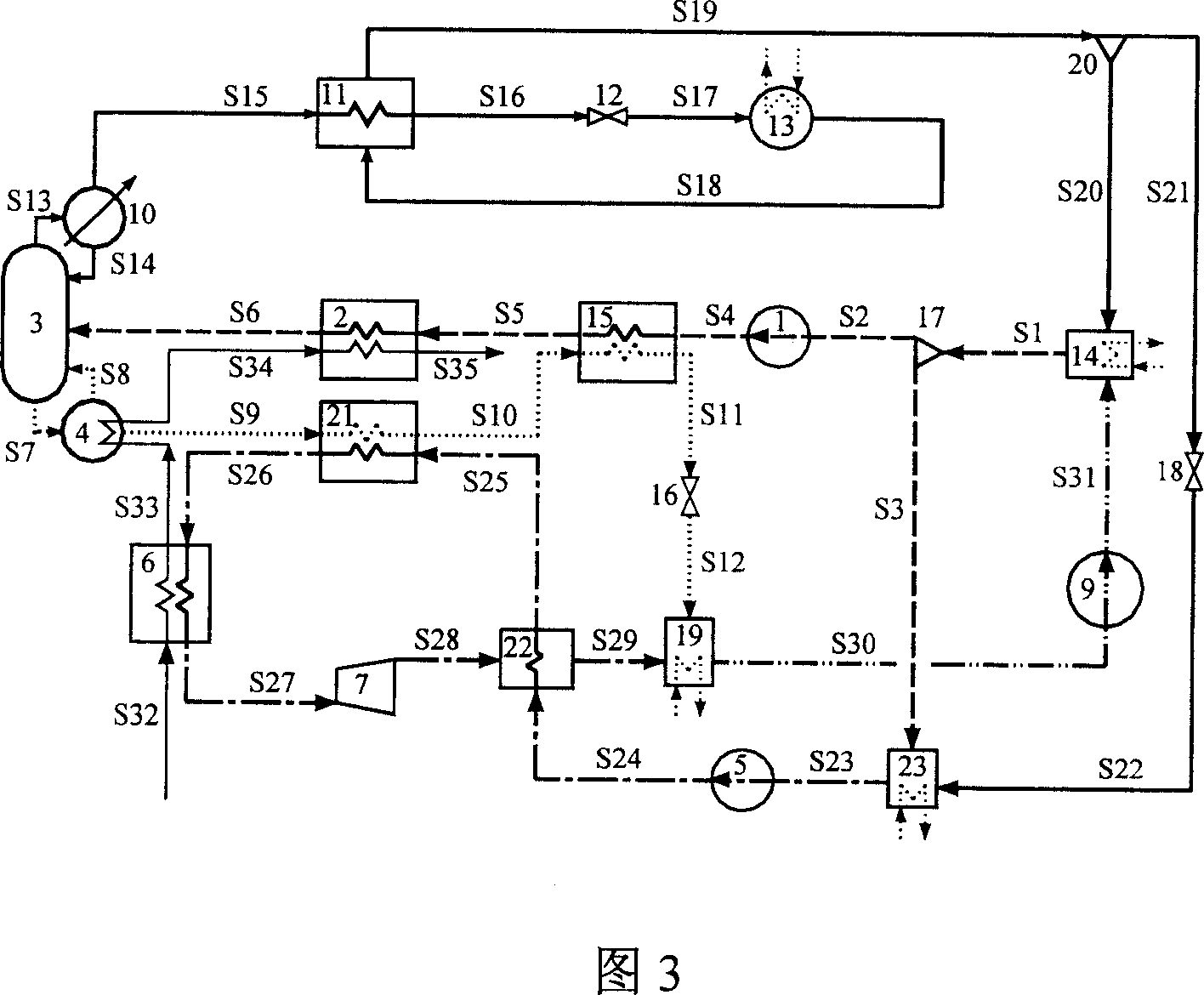

[0057] The system of this embodiment consists of pumps 1, 5, 9, heat exchangers 2, 15, rectification tower 3 (including tower bottom reboiler 4 and tower top condenser 10), waste heat boiler 6, steam turbine 7, cooler 11. Throttle valves 12, 16, 18, evaporator 13, high-pressure absorber 14, splitters 17, 20, low-pressure absorber 19, preheater 21, regenerator 22, and medium-pressure absorber 23. The specific process is as follows: in the refrigeration reverse cycle, the basic concentration ammonia water working substance S1 is divided into S2 and S3 through the flow divider 17, wherein S2 is used as the feed of the rectification tower and is boosted by the pump 1, and then heated in the heat exchangers 15 and 2 The saturated liquid S6 is sent to the rectification tower 3 and divided into dilute ammonia solution S7 and concentrated ammonia vapor S13.

[0058] The dilute ammonia solution S7 produced at the bottom of the rectification tower absorbs heat in the reboiler 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com