Ionic bond jointed phosphor - nitrogen type flame retardant, and preparation method

A technology of flame retardant and ionic bond, which is applied in the field of phosphorus-nitrogen flame retardant and its preparation, to achieve the effects of high flame retardant efficiency, simple equipment and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

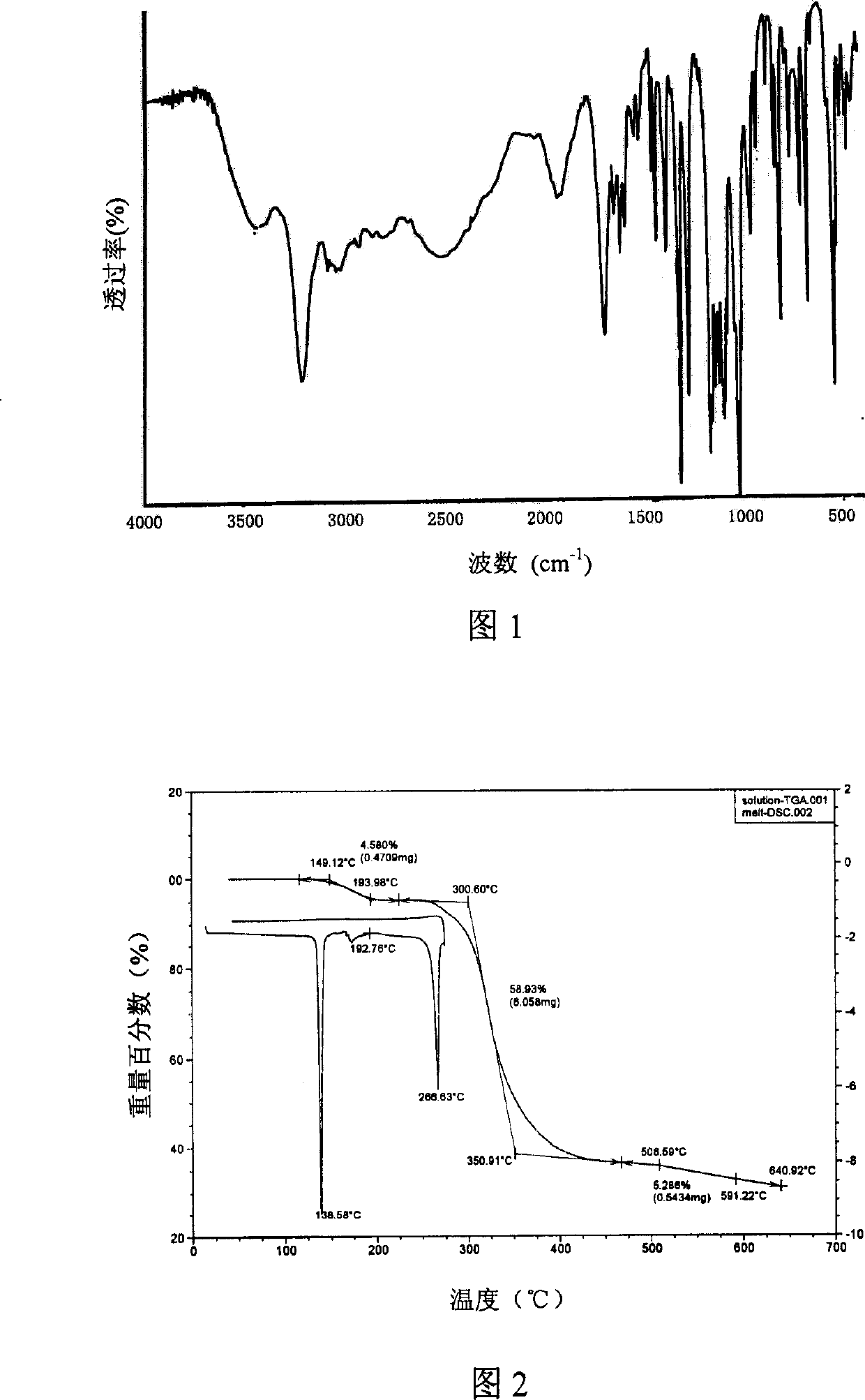

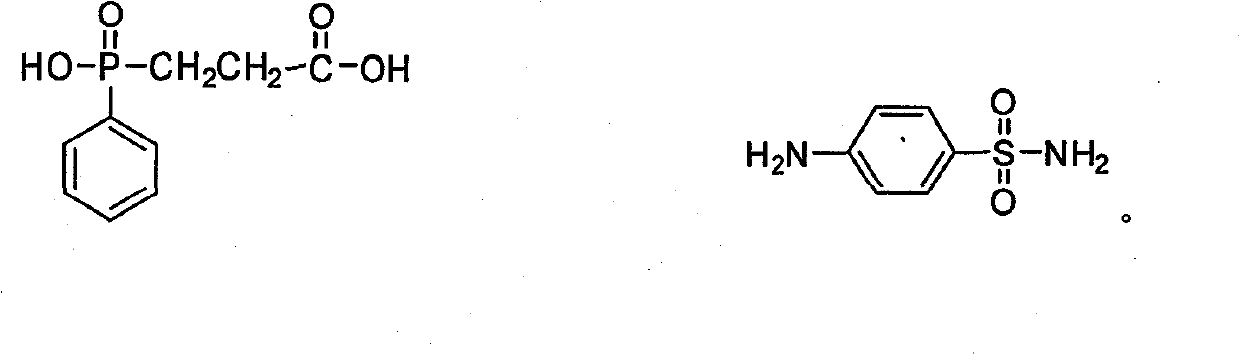

Image

Examples

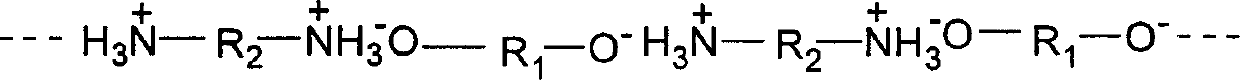

Embodiment 1

[0039] Weigh 17.12 g (0.08 mol) of hydroxyphenoxyphosphine propionic acid (CEPP) and add it into a three-necked flask equipped with 80 ml of deionized water, heat and stir with a magnetic stirrer, and raise the temperature to 65 ° C to completely dissolve CEPP, and then Add 13.76g (0.08mol) of p-aminobenzenesulfonamide (SAA), and react at a reaction temperature of 80°C for 0.5h, then stop heating, cool to 30°C, a large amount of white product precipitates out, continue to cool to room temperature, separate After drying, a milky white solid product was obtained with a yield of 99.0%.

Embodiment 2

[0041] Weigh 10.70 g (0.05 mol) of hydroxyphenoxyphosphine propionic acid (CEPP) and 1.36 g of natural montmorillonite into a three-necked flask filled with 60 ml of deionized water, heat and stir with a magnetic stirrer, and raise the temperature to 20°C Dissolve CEPP completely, then add 6.30g (0.05mol) of melamine, and react at a reaction temperature of 80°C for 2.5h, stop heating, cool to 20°C, a large amount of white product precipitates out, continue to cool to room temperature, separate and dry The milky white solid product was obtained with a yield of 98.0%.

Embodiment 3

[0043]Weigh 12.64g (0.08mol) of phenylphosphonic acid and 0.0028g of magnesium chloride into a three-necked flask filled with 50ml of deionized water, heat and stir with a magnetic stirrer, and raise the temperature to 25°C to completely dissolve the phenylphosphonic acid. Then add 13.76g (0.08mol) of p-aminobenzenesulfonamide, and react at a reaction temperature of 40°C for 1.0h, then stop heating, cool to room temperature, and precipitate the product with methanol as a precipitant, separate and dry to obtain a milky white solid Product, the yield was 97.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com