Retainer for rolling bearing, and rolling bearing

A rolling bearing and cage technology, applied in the direction of ball bearings, bearing components, shafts and bearings, etc., to achieve the effects of excellent durability, good durability and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

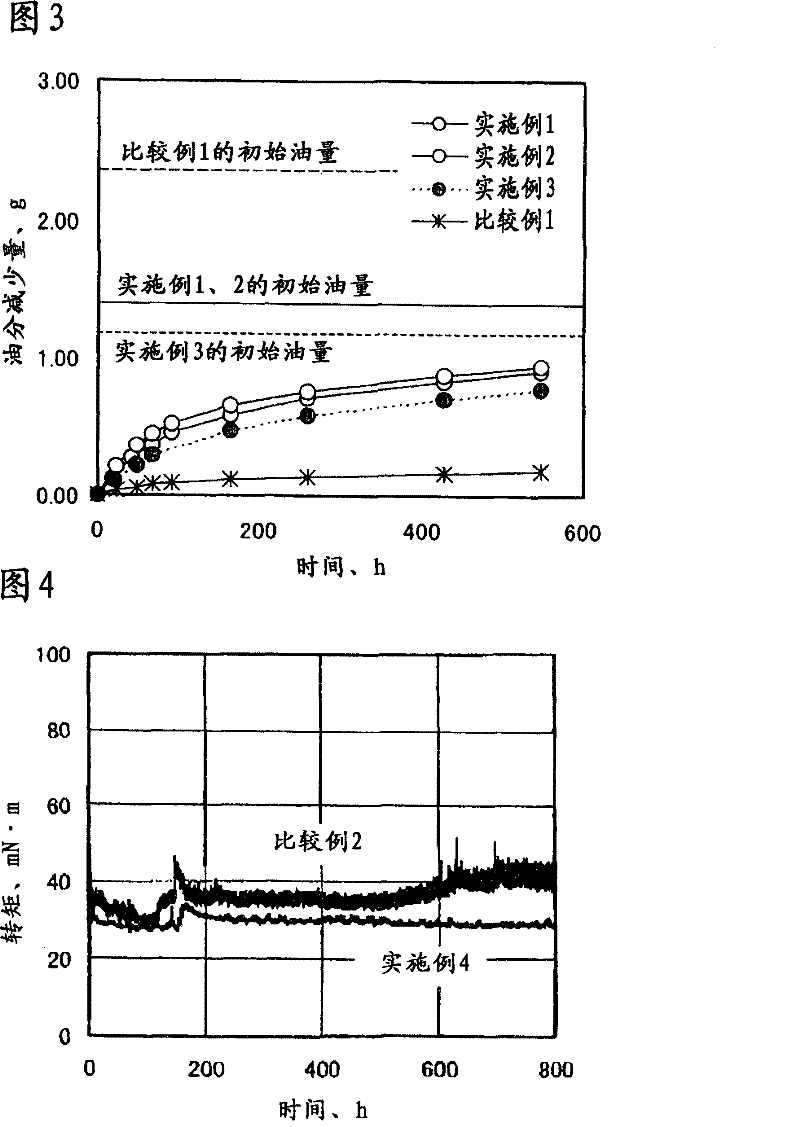

[0183] Ultra-high molecular weight polyethylene powder (Mipelon XM220 manufactured by Mitsui Chemicals Co., Ltd.) and sodium benzoate powder (reagent manufactured by Wako Pure Chemical Industries, Ltd.) were mixed in a mixer at a volume ratio of 50:50 for 5 minutes to obtain a mixed powder. Using this mixed powder, a disk having a diameter of 30 mm in diameter and a thickness of t5 mm was molded by heating and compression molding (200° C. for 30 minutes). This compact was washed with an ultrasonic cleaner in warm water at 80° C. for 10 hours, and sodium benzoate powder was eluted. Then, it was dried at 100° C. for 8 hours to obtain a porous body with a continuous porosity of 48%. In this porous body, polyalphaolefin oil (PAO) (manufactured by Nippon Steel Chemical Co., Ltd., Synfur-do 801 (viscosity 46mm) was vacuum-impregnated at 60°C. 2 / s(40℃)). The oil content was 45% based on the total volume. Using this sample, an immersion oil bleed test, which is an important chara...

Embodiment 2

[0185] Tetrafluoroethylene powder (M15 manufactured by Daikin Industries, Ltd.) and sodium benzoate powder (reagent manufactured by Wako Pure Chemical Industries, Ltd.) were mixed in a mixer at a volume ratio of 50:50 for 5 minutes to obtain a mixed powder. Using this mixed powder, a disk having a diameter of 30 mm in diameter and a thickness of t5 mm was molded by heating and compression molding (350° C. for 30 minutes). This compact was washed with an ultrasonic cleaner in warm water at 80° C. for 10 hours, and sodium benzoate powder was eluted. Then, it was dried at 100° C. for 8 hours to obtain a porous body with a continuous porosity of 48%. Synthetic hydrocarbon oil (Lu-kanto HC-20 (viscosity: 155 mm) manufactured by Mitsui Chemicals Co., Ltd. 2 / s(40℃)). The oil content was 44% based on the total volume. This sample was used for the immersion oil bleed test.

Embodiment 3

[0187] Polyetheretherketone (PEEK) resin powder (Victrex Co., Ltd. 150PF) and carbon fiber and sodium benzoate powder (Wako Pure Chemical Co., Ltd. reagent) were mixed with Brabender powder at a volume ratio of 50:10:40. It was melted and kneaded in a mass analyzer, and then pulverized to obtain a mixed powder. Using this mixed powder, a disk having a diameter of 30 mm in diameter and a thickness of t5 mm was molded by heating and compression molding (350° C. for 30 minutes). This compact was washed with an ultrasonic cleaner in warm water at 80° C. for 10 hours, and sodium benzoate powder was eluted. Then, it was dried at 100° C. for 8 hours to obtain a porous body with a continuous porosity of 39%. In this porous body, polyalphaolefin oil (PAO) (Silver-do 801 (viscosity 46mm) manufactured by Nippon Steel Chemical Co., Ltd. was vacuum-impregnated at 60°C. 2 / s(40℃)). The oil content was 38% based on the total volume. This sample was used for the immersion oil bleed test. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com