In-situ observation system combining laser light scattering and microscope under the shear field

A technology of laser light scattering and shear field, which is applied in the measurement of scattering characteristics, the use of stable shear force to test the strength of materials, fluorescence/phosphorescence, etc., which can solve the discomfort, no microscope part, and the inability to directly observe large-scale structures and other issues to achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

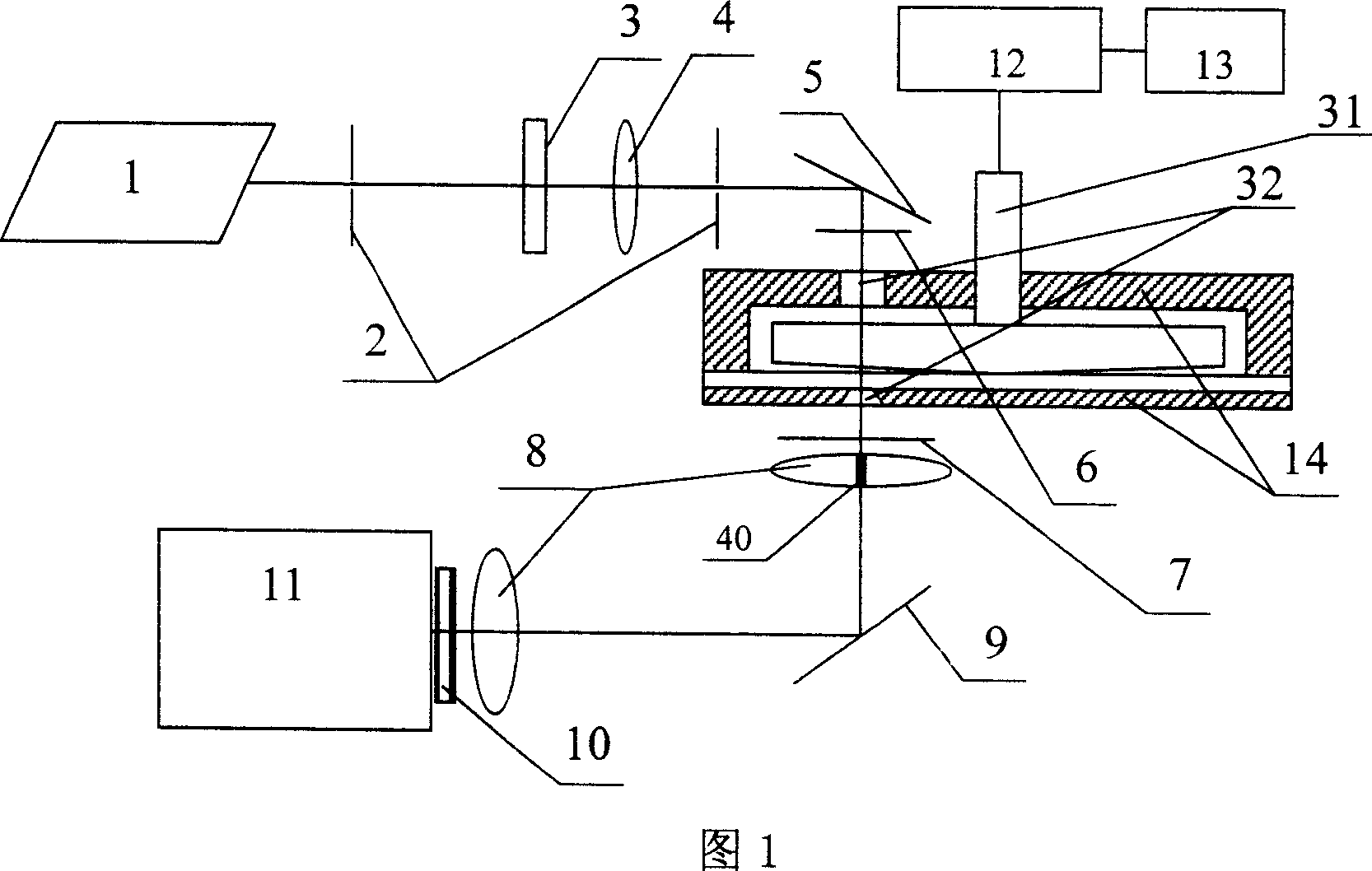

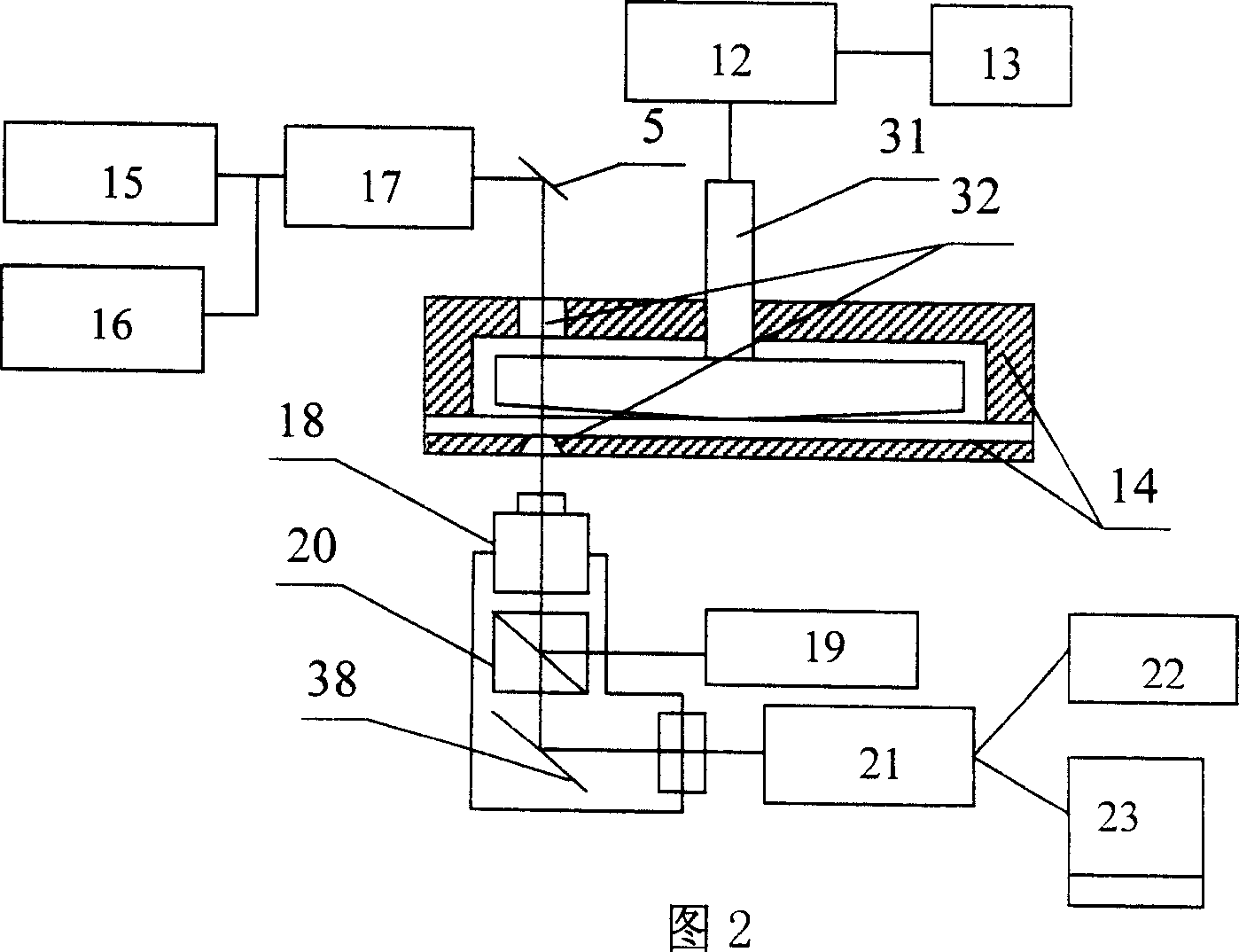

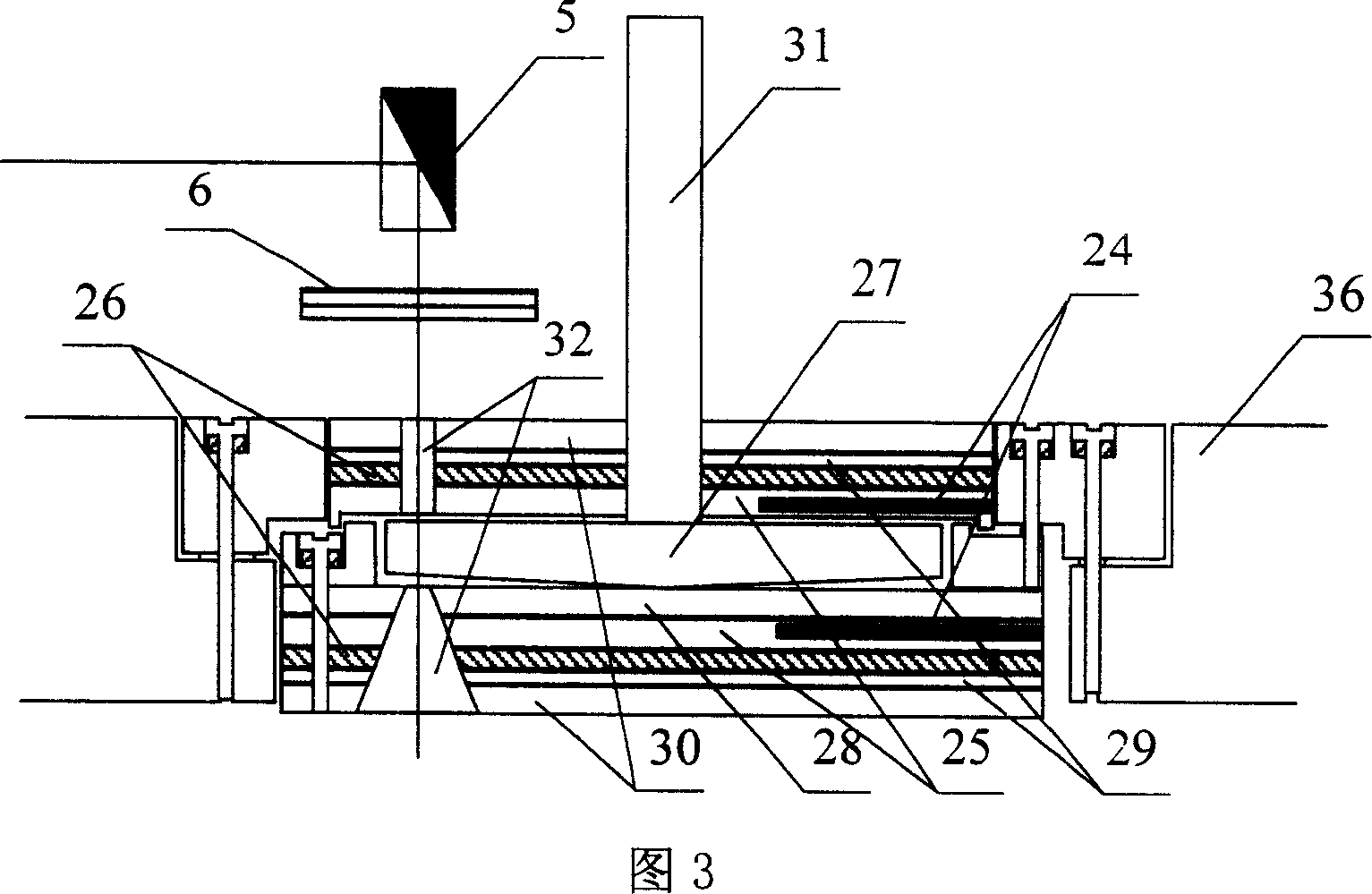

[0060] See Figure 4. The present invention includes a laser light scattering and microscope system, a sample pool 14 with a heater on a platform 36 shared by the two systems, a precise and controllable shear field applying device and a total reflection coating mirror 5 .

[0061] The power application device 12 driven by a micro-stepping motor and the controller 13 that constitute an accurate and controllable shear field application device are installed on the platform 36, and the controller 13 is connected with a computer through a data line; the power application device driven by a micro-stepping motor The device 12 is composed of a precision milling head 33, a rotating shaft 31 made of invar alloy, and a micro-stepping motor with an encoder to precisely control the speed and position; wherein, the cantilever 39 on the precision milling head 33 is installed There is a micrometer 37, which is used to measure the distance between the upper plate 27 of the sample cell quartz an...

Embodiment 2

[0076] With the system and operating method of Example 1, the phthalic acid dioctanoic acid of polystyrene / polybutadiene with 4-chloro-7-nitrobenzene-2-oxygen-1,3 oxadiazole Solution (NBD-PS / PB in DOP) system was measured. Adopt, the phase diagram is the upper critical solution temperature type (UCST), adopt 8% polystyrene / polybutanediene with 4-chloro-7-nitrobenzene-2-oxo-1,3 oxadiazole as fluorescent label ene (NBD-PS / PB, NBD-PS:M w =9.5×10 4 ,M w / M n = 1.03, PS / NBD = 300 / 1; PB: M w =2.2×10 4 ,M w / M n =1.1) of phthalic acid dicaprylic acid solution, the results of phase contrast microscopy and fluorescence microscopy (using an excitation wavelength of 480±20nm) of the polystyrene-rich region in the unstable region at 22°C are shown in Figure 9. When working in bright field and polarized microscope mode, bright field and polarized light source or flash light source is used to illuminate the sample at the set temperature in the sample cell with shear motion applied, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com