Waste aluminium slag improved aluminia producing Bayer process with diaspore

A technology of aluminum waste slag and Bayer method, applied in the direction of alumina/hydroxide, etc., can solve the problems of poor decomposition performance and achieve the effect of saving resources and improving production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

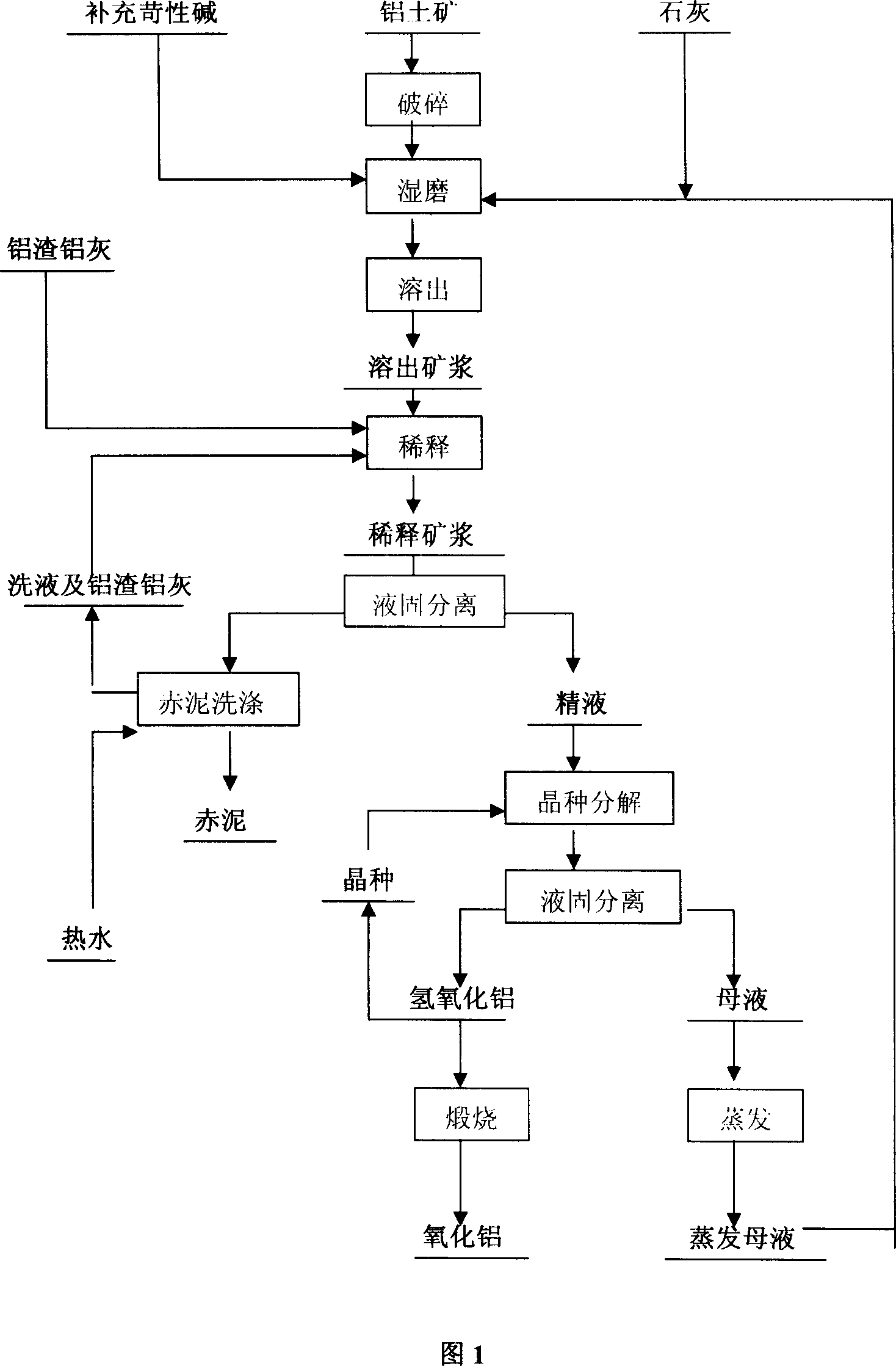

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the chemical composition (each element content is all converted into oxide, by weight %) of one of aluminum slag aluminum ash used is:

[0018] Alumina (Al 2 o 3 ) 73.56 Silicon oxide (SiO 2 ) 11.17

[0019] Magnesium oxide (MgO) 5.67 Calcium oxide (CaO) 1.06

[0020] Iron oxide (Fe 2 o 3 ) 0.95 Titanium oxide (TiO 2 ) 0.30

[0021] Other 7.29

[0022] Circulating lye concentration: alumina 141.1g / l, caustic alkali 279.8g / l; molecular ratio 3.26.

[0023] Concentration of high-pressure stripping pulp (liquid phase): alumina 279.1g / l, caustic alkali 255.4g / l; molecular ratio 1.51.

[0024] During the dilution process with red mud wash solution per m 3 Add 50kg of the above-mentioned aluminum slag and aluminum ash to the high-pressure stripping slurry, stay for 30 minutes, and separate the liquid from the solid to obtain the semen concentration: alumina 158.3g / l, caustic alkali 143.2g / l; molecular ratio 1.49.

[0025] The obtained semen can be dec...

Embodiment 2

[0026] Embodiment 2: The chemical composition of the aluminum slag and aluminum ash used is the same as in Embodiment 1.

[0027] Circulating lye concentration: alumina 87.9g / l, caustic alkali 192.9g / l; molecular ratio 3.61.

[0028] Concentration of high pressure stripping pulp (liquid phase): alumina 239.4g / l, caustic alkali 229.0g / l; molecular ratio 1.57.

[0029] During the dilution process with red mud wash solution per m 3 Add 50kg of the above-mentioned aluminum slag and aluminum ash to the high-pressure stripping slurry, stay for 30 minutes, and separate the liquid from the solid to obtain the semen concentration: alumina 154.1g / l, caustic alkali 138.4g / l; molecular ratio 1.48.

[0030] The obtained semen can be decomposed for 50-55 hours under the conditions of an initial decomposition temperature of 65-70°C, a final temperature of 45-50°C, and a seed crystal coefficient of 1.5. The decomposition rate can reach 50-52%, and sandy alumina can basically be obtained.

Embodiment 3

[0031] Embodiment 3: the chemical composition (each element content is all converted into oxide, by weight %) of one of aluminum slag aluminum ash used is:

[0032] Alumina (Al 2 o 3 ) 73.56 Silicon oxide (SiO 2 ) 11.17

[0033] Magnesium oxide (MgO) 5.67 Calcium oxide (CaO) 1.06

[0034] Iron oxide (Fe 2 o 3 ) 0.95 Titanium oxide (TiO 2 ) 0.30

[0035] Other 7.29

[0036] Circulating lye concentration: alumina 141.1g / l, caustic alkali 279.8g / l; molecular ratio 3.26.

[0037] Concentration of high-pressure stripping pulp (liquid phase): alumina 279.1g / l, caustic alkali 255.4g / l; molecular ratio 1.51.

[0038] During the dilution process with red mud wash solution per m 3 Add 20kg of the above-mentioned aluminum slag and aluminum ash to the high-pressure stripping slurry, stay for 30 minutes, and separate the liquid from the solid to obtain the semen concentration: alumina 150.3g / l, caustic alkali 145.2g / l; molecular ratio 1.50.

[0039] The obtained semen can be dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com