Prepn process of nanometer titania ring

A titanium dioxide and nano-ring technology, applied in the fields of chemistry and chemical industry, can solve the problems of high cost, expensive equipment and the like, and achieve the effects of low cost, simple preparation process and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

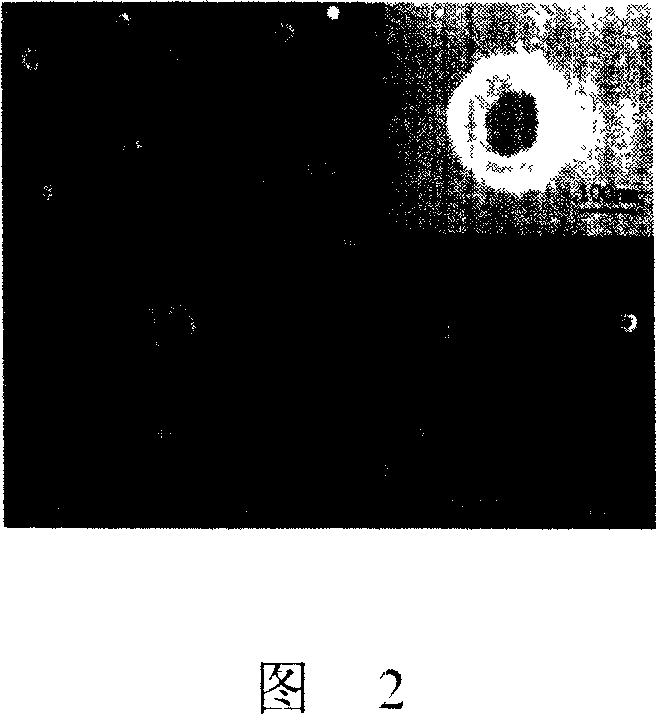

[0008] TiO of the present invention 2 The preparation method of nano ring is made by following steps:

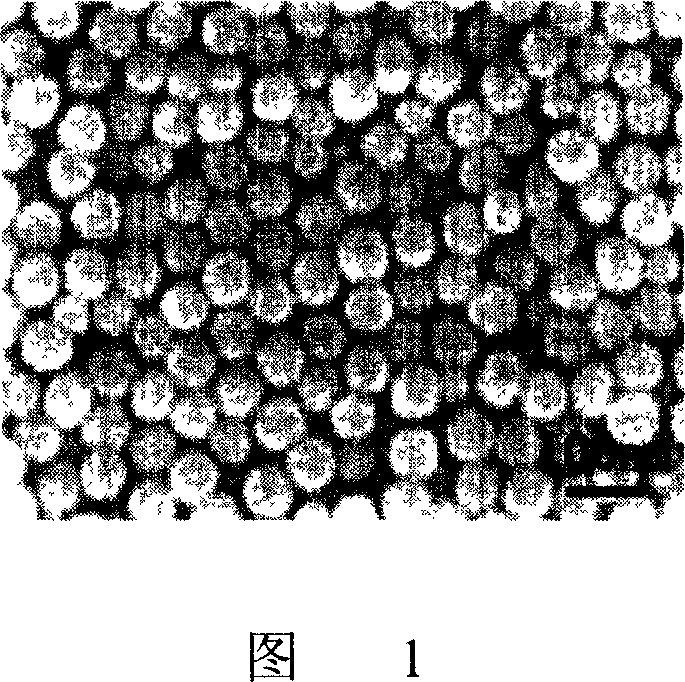

[0009] (1) Prepare polystyrene nanosphere emulsion by emulsion polymerization: polystyrene nanosphere emulsion is made of monomer styrene, emulsifier sodium lauryl sulfate, buffering agent sodium bicarbonate, water and initiator potassium persulfate Prepared by emulsion polymerization in a constant temperature water bath at 80°C, the molar ratio of styrene, sodium lauryl sulfate, sodium bicarbonate, water and potassium persulfate is 1:0.001~0.01:0.005~0.05:20~60: 0.005~0.05. In the emulsion, the size of the polystyrene balls is uniform, and the diameter is between 40 and 100 nm.

[0010] (2) Preparation of TiO by sol-gel method 2 Sol: Mix butyl titanate, absolute ethanol and diethanolamine in a molar ratio of 1:2-10:0.2-0.5, and mix them for 2-3 hours under constant stirring to obtain TiO 2 Sol.

[0011] (3) Polystyrene emulsion and TiO 2 After the sol is stirred and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com