Modified polyacetal self-lubricating composite material, and its preparing method

A composite material and polyoxymethylene technology, which is applied in the field of modified polyoxymethylene self-lubricating composite material and its preparation, can solve the problems of narrow processing and molding temperature, difficulty, mechanical properties decline, etc., and achieves good mechanical properties, high production efficiency, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

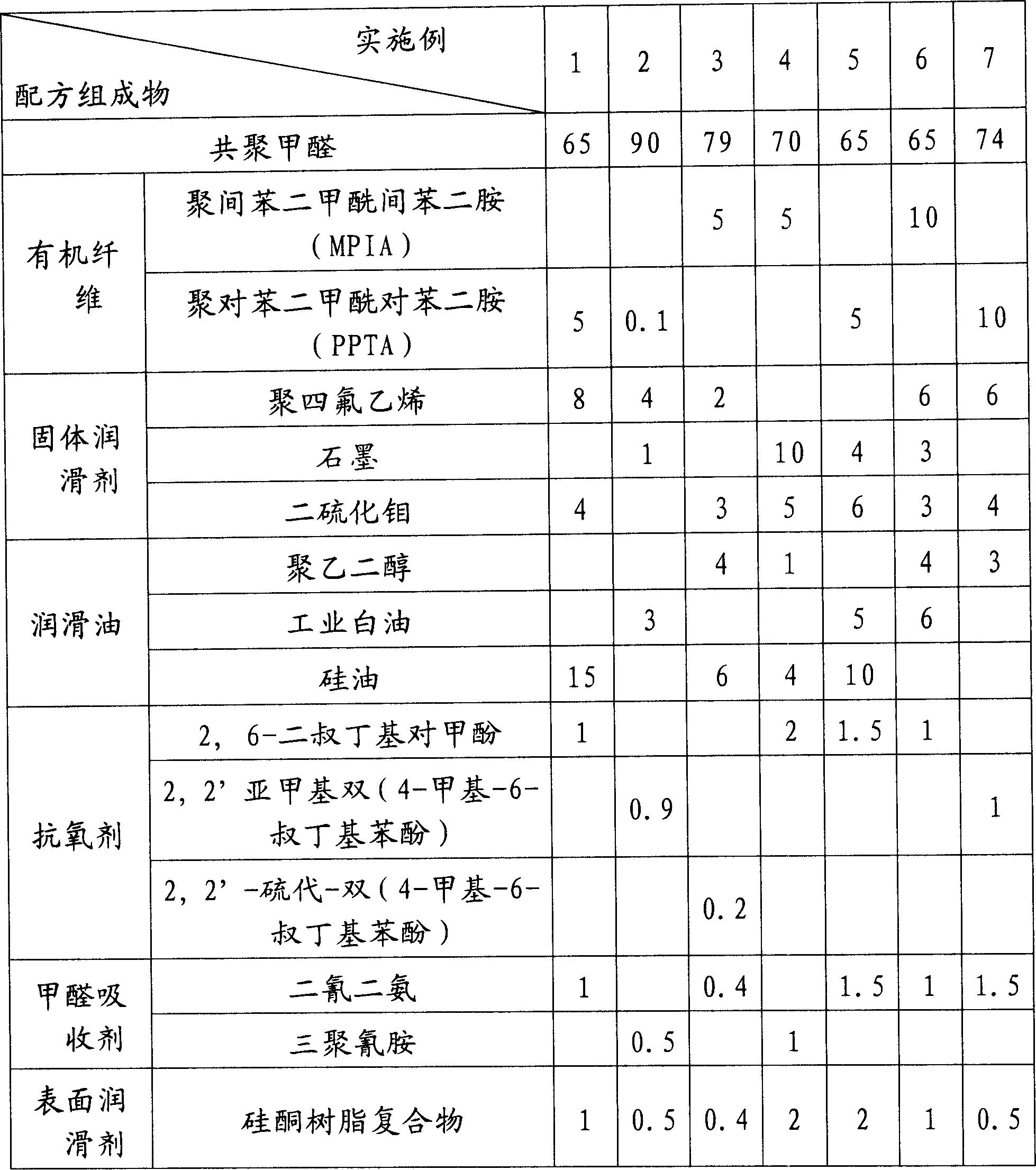

[0030]Embodiment 1: The prepared material, the specific composition is as shown in embodiment 1. Mix the above-mentioned materials at a high speed, and feed them in one time from the main feeder, and granulate under the conditions of the barrel temperature of the twin-screw extruder is 170-190°C, and the rotation speed is 80rpm. After the granulated material is dried, it is molded by a screw-type injection molding machine with a cylinder temperature of 185-230°C, and the smooth-surfaced sliding parts are injection-molded.

Embodiment 2

[0031] Embodiment 2: the prepared material, the specific proportion is as shown in embodiment 2. Mix and impregnate the above-mentioned fiber and lubricating oil, mix with POM and additives at high speed, add from the main feeder, mix the solid lubricant at high speed, and add from the secondary feeder, the barrel temperature of the twin-screw extruder is 170~ Granulate at 190°C and 120 rpm. It is molded by a screw type injection molding machine, and the temperature of the barrel is 185-230°C, and the sliding parts with smooth surfaces are injection-molded.

Embodiment 3

[0032] Embodiment 3: the prepared material, the specific proportion is as shown in embodiment 3. Mix POM and processing aids at high speed and add them from the main feeder; mix solid lubricants at high speed and add them from the secondary feeder. After the fibers and lubricating oil are fully impregnated, add them from the glass fiber inlet of the extruder. Twin-screw The temperature of the extruder barrel is 170-190° C., and the rotation speed is 120 rpm. At the exit of the sheet die, a sheet with a thickness of 1.0 mm is prepared through a calendering and winding device. Through the sintering furnace, the modified polymer material is compounded with the steel plate of sintered spherical copper powder, quickly taken out, rolled, and the surface modified layer thickness is 0.4mm. Multi-layer composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com