Method for preparing small-particle-size water-soluble cadium selenide quantum dot and its use

A cadmium selenide, quantum dot technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high flammability of synthetic raw materials, restricted further use, harsh preparation conditions, etc., and achieves low price, good monodispersity, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

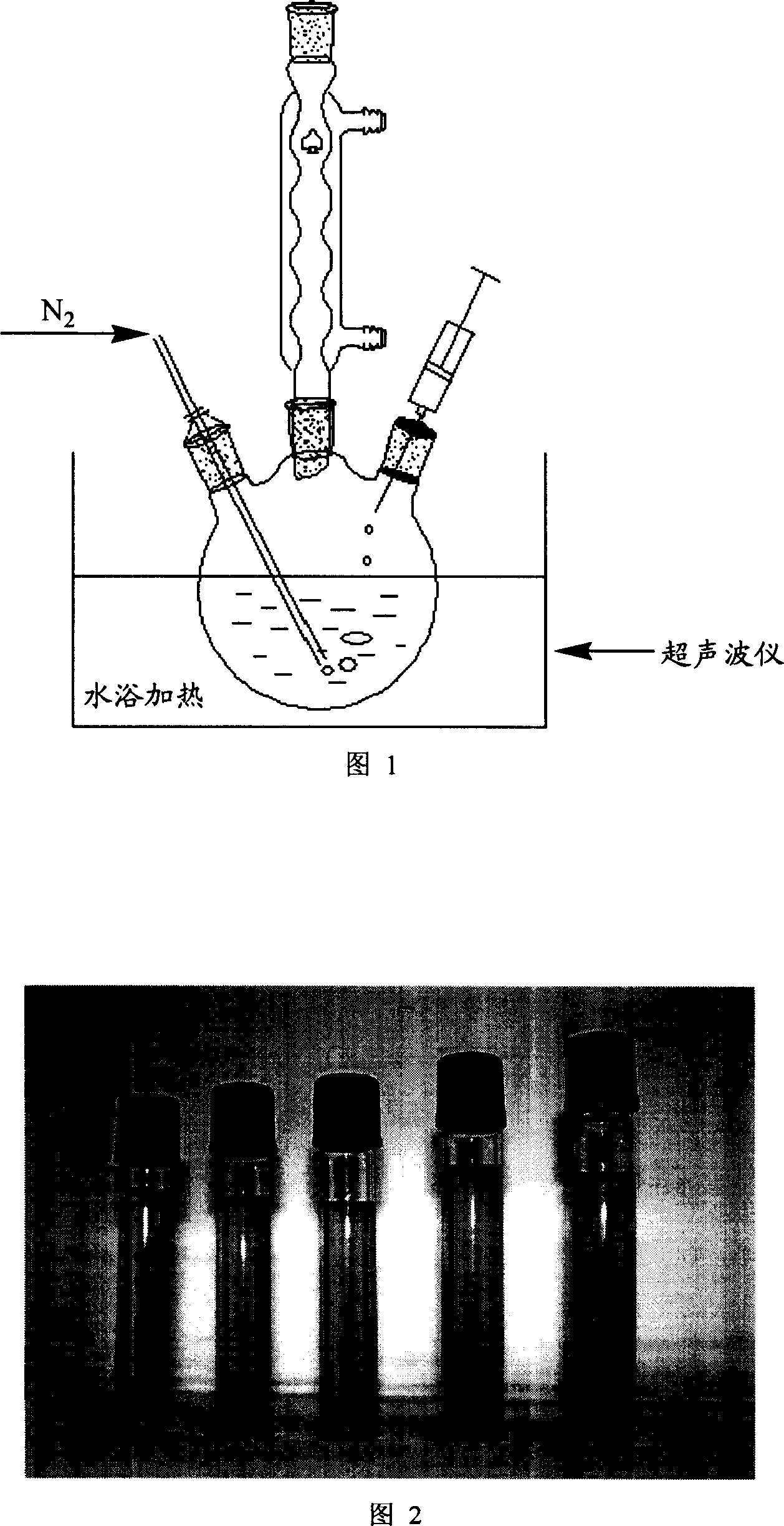

[0024] 1. Weigh 684mg of cadmium chloride (analytical pure, produced by China Hengxin Chemical Reagent Factory, the same below), dissolve it in 50ml ultrapure water and prepare a solution with a concentration of 0.06mol / L, and add this solution to the solution shown in Figure 7. Into the 100mL three-neck round bottom flask shown in Fig. 1, pass high-purity nitrogen (99.99%, the same below) to remove oxygen for 30min, add thioglycolic acid (analytical grade, produced by Sinopharm Chemical Reagent Co., Ltd., the same below) 30μL, and use 1mol / L NaOH solution adjusts its pH value to 11;

[0025] 2. Weigh 158mg of selenium powder (purity: 99.99%, produced by Tianjin Guangfu Fine Chemical Research Institute), add it to a sodium sulfite solution with a concentration of 0.2mol / L, heat and reflux at 150°C for 60 minutes, and then cool to room temperature (25 DEG C, the same below), make sodium selenosulfate stock solution;

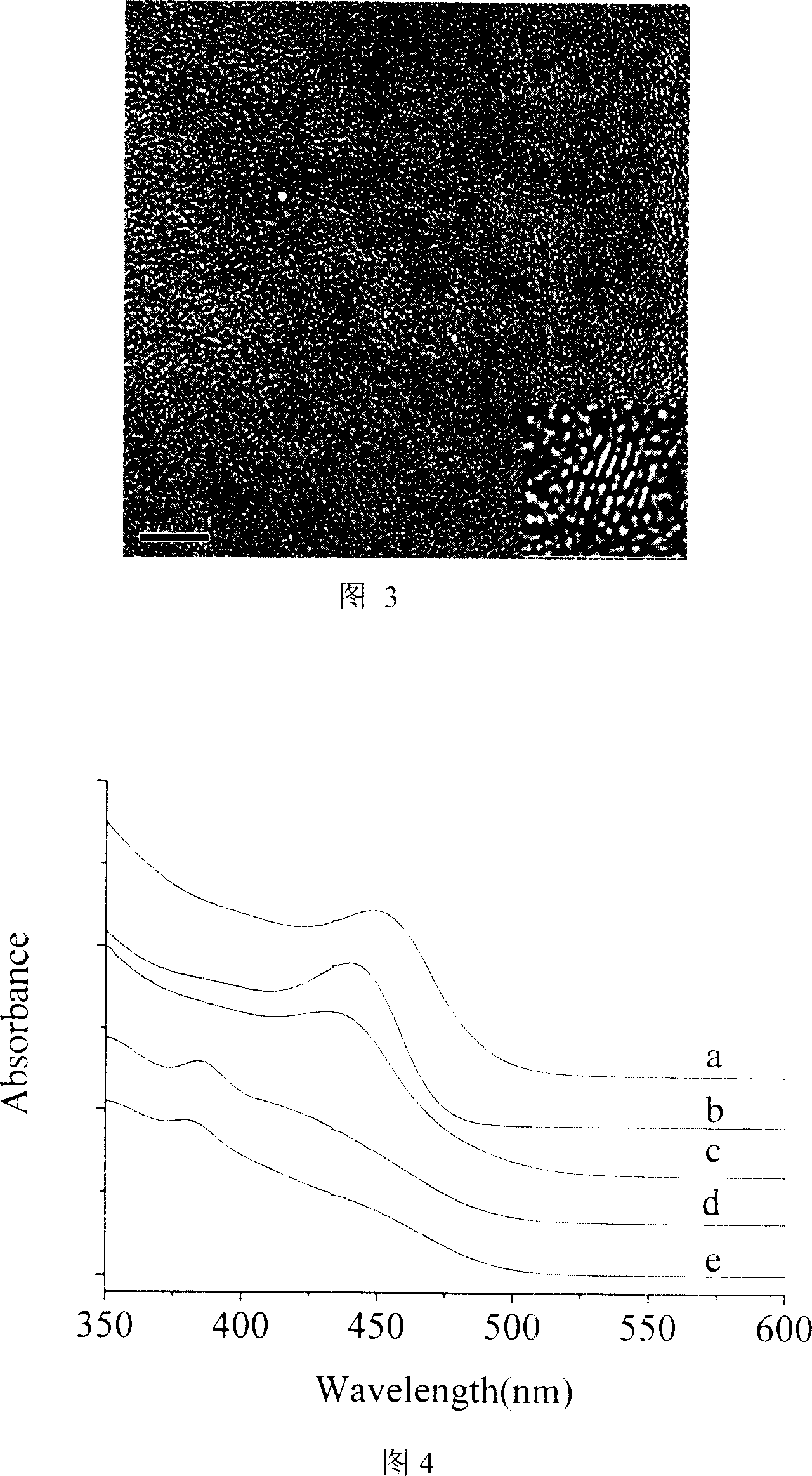

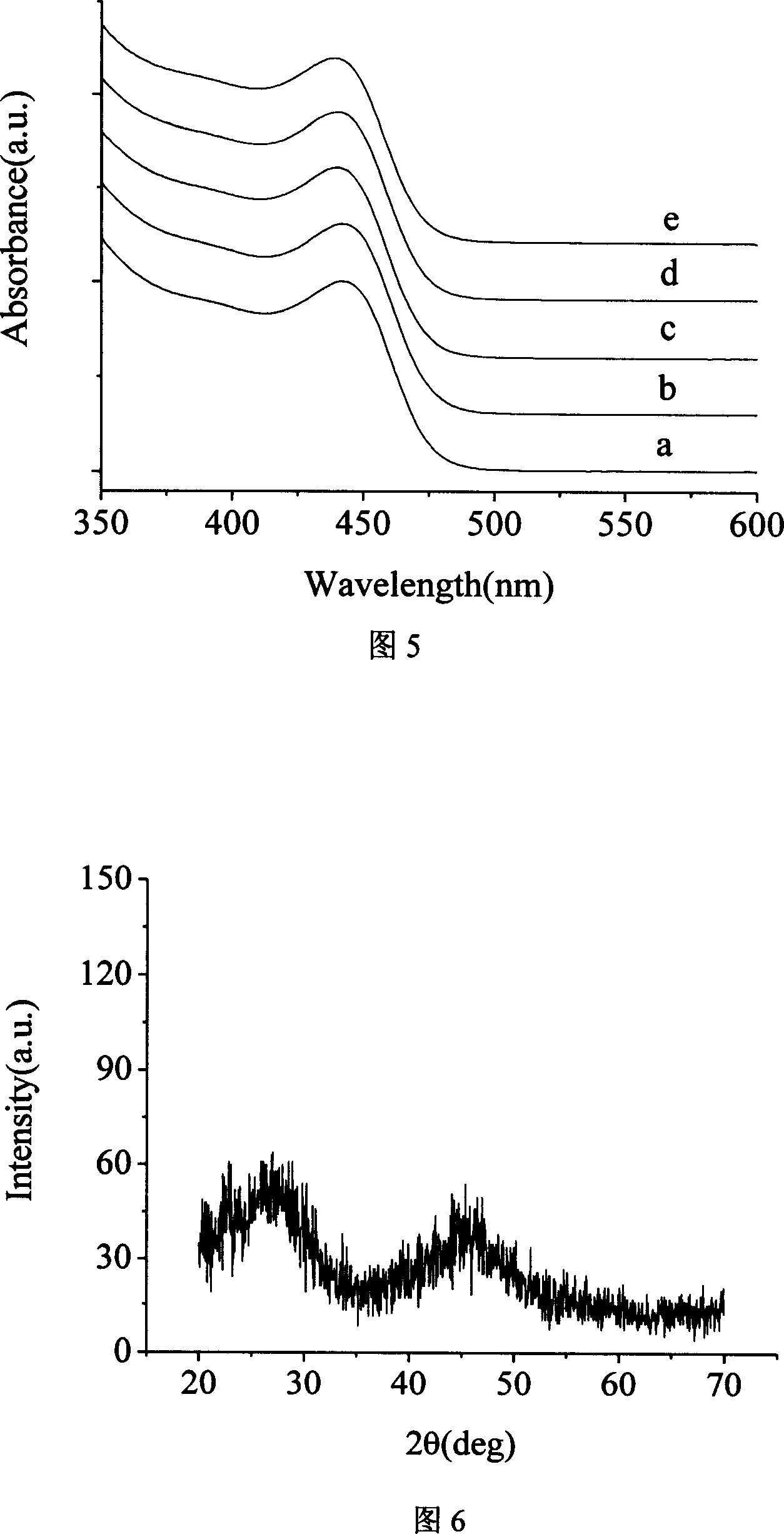

[0026] 3. In a water bath at about 90°C, under the control ...

Embodiment 2

[0029] l. Weigh 340 mg of cadmium chloride, dissolve it in 50 ml of ultrapure water to prepare a solution with a concentration of 0.03 mol / L, add this solution into a 100 mL three-necked round-bottomed flask as shown in Figure 7, and pass high-purity nitrogen to remove oxygen After 20 minutes, add 10 μL of thioglycolic acid and adjust its pH to 10 with 0.5 mol / L NaOH solution;

[0030] 2. Weigh 256 mg of selenium powder, add it to a sodium sulfite solution with a concentration of 0.1 mol / L, heat and reflux at 150°C for 30 minutes, and then lower it to room temperature (25°C) to prepare a sodium selenosulfate stock solution;

[0031] 3. In a water bath at about 90°C, under the control of an ultrasonic cleaner (the operating frequency of the ultrasonic cleaner is: 20KHz, and the power is 60Wcm -2, Ningbo Xinzhi Biotechnology Co., Ltd.), 20ml of newly prepared sodium selenosulfate solution was quickly added to the solution prepared in step 1, and the color of the solution changed...

Embodiment 3

[0033] 1. Weigh 910 mg of cadmium chloride, dissolve it in 50 ml of ultra-pure water to prepare a solution with a concentration of 0.08 mol / L, add this solution into a 100 mL three-necked round-bottomed flask as shown in Figure 7, and pass high-purity nitrogen gas to remove oxygen After 40 minutes, add 30 μL of thioglycolic acid, and adjust its pH value to 12 with 2mol / L NaOH solution;

[0034] 2. Weigh 395 mg of selenium powder, add it to a sodium sulfite solution with a concentration of 0.25 mol / L, heat and reflux at 150° C. for 90 minutes, and then lower it to room temperature (25° C.) to obtain a sodium selenosulfate stock solution;

[0035] 3. In a water bath at about 90°C, under the control of an ultrasonic cleaner (the operating frequency of the ultrasonic cleaner is: 20KHz, and the power is 60Wcm -2 , Ningbo Xinzhi Biotechnology Co., Ltd.), 20ml of newly prepared sodium selenosulfate solution was quickly added to the solution prepared in step 1, and the color of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com