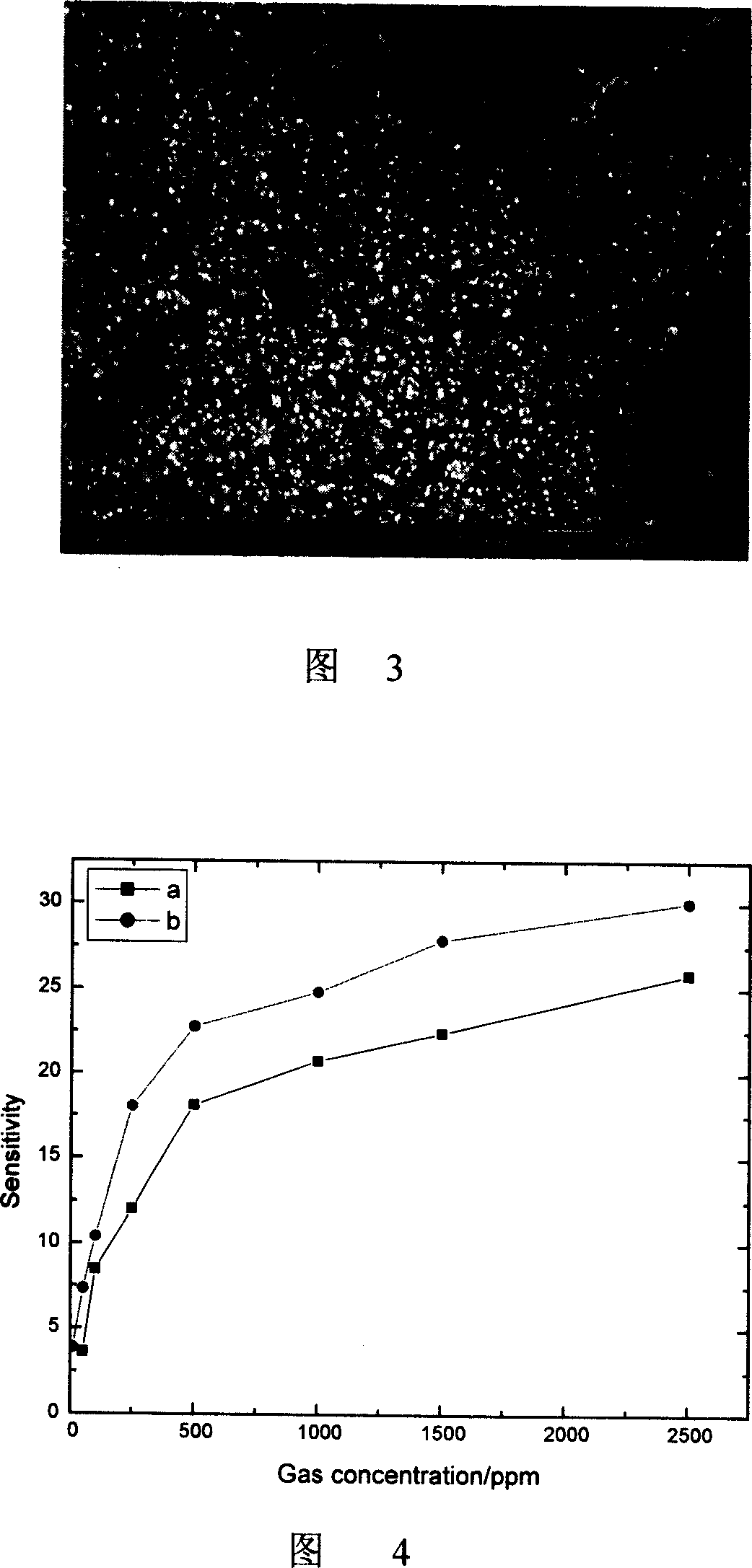

Preparing process of nano ZnO line array coated with nano TiO2 particles

A nanowire array and nanoparticle technology, which is applied in the field of preparation of ZnO nanowire arrays, can solve the problems of ZnO nanowire chemical properties are not stable enough, easy to be corroded, etc., and achieve the effect of improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: preparation surface is coated with TiO 2 The experimental procedure of the ZnO nanowire array of nanoparticles is divided into the following four steps:

[0021] The first step: the preparation of the alcohol sol of zinc oxide and titanium dioxide;

[0022] 1) Put 250ml of absolute ethanol and 5.4g of zinc acetate into a distillation bottle, heat under reflux at 90-100°C until the zinc acetate is completely dissolved, and continue boiling for 30-60 minutes. Take 1.47g of lithium hydroxide and put it into the cooled mixed solution, supersonize it in an ultrasonic machine for 1 hour to dissolve the lithium hydroxide, and then filter the solution to obtain the zinc oxide sol.

[0023] 2) Put 100ml of ethanol and 34ml of butyl titanate into a beaker, stir evenly, and then add 11ml of diethanolamine into the beaker. After mixing 55ml of ethanol and 9ml of water, pour it into the above mixed solution, and then stir for 3-5 hours to obtain an organosol of titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com