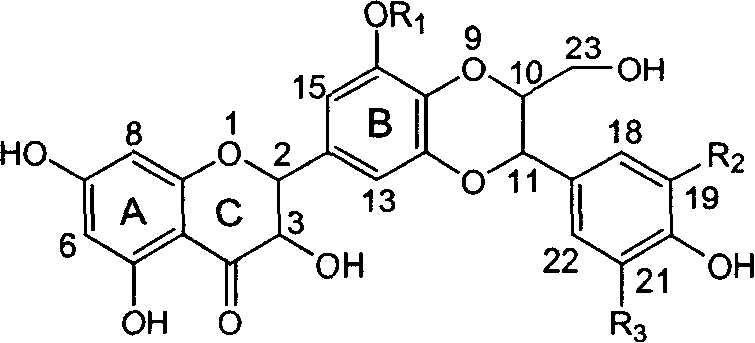

Silybin flavonolignan and their production method and use

A technology of lipids and medicinal salts, applied in the field of organic chemistry and medicinal chemistry, can solve problems such as insufficient water solubility and bioavailability, and limited drug market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

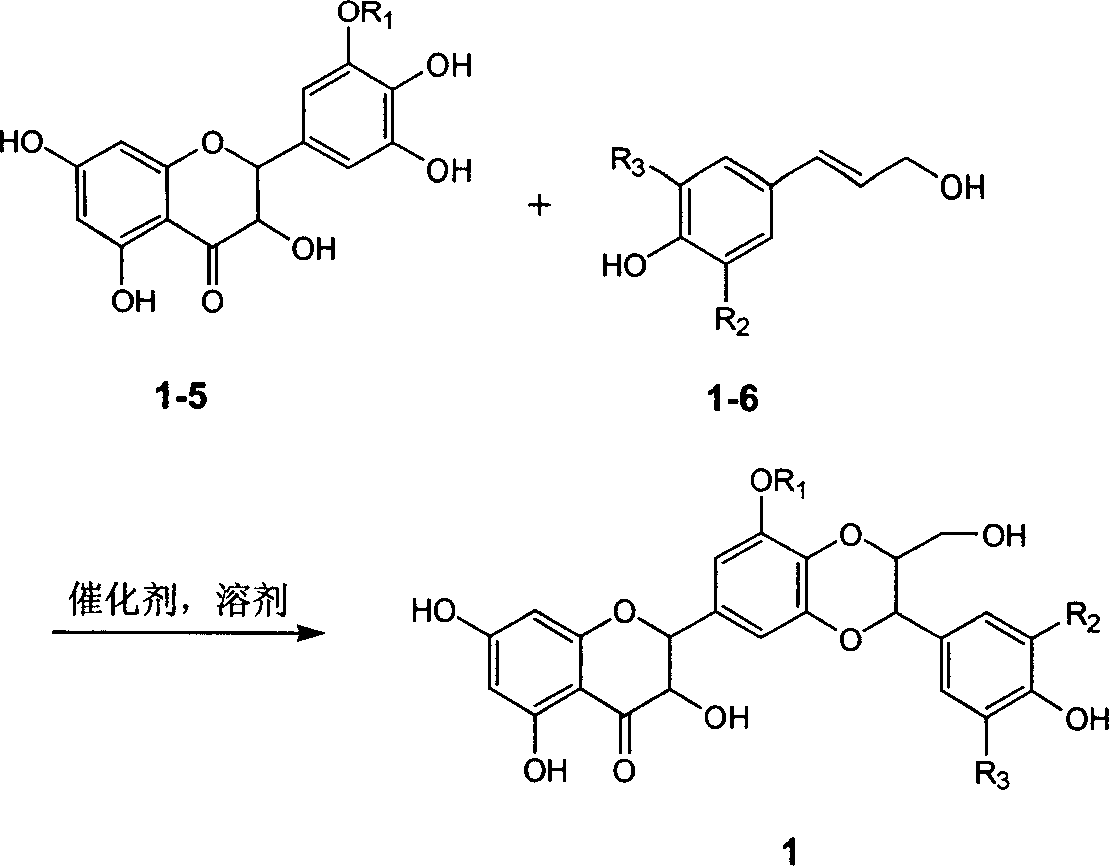

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Compound 1-3-1(1-(2,4,6-trimethoxymethoxyphenyl)-3-(3,4-dimethoxymethoxy-5-methoxyphenyl ) Preparation of propylene ketone):

[0040]

[0041] 3 grams of 3-methoxy-4,5-dimethoxymethoxybenzaldehyde and 3.5 grams of 2,4,6-trimethoxymethoxyacetophenone are dissolved in 40mL ethanol, and 10g potassium hydroxide is added. 20mL aqueous solution, stirred at room temperature for 15 hours. Ethanol was evaporated under reduced pressure, 30 mL of water was added, and extraction with ethyl acetate (3×20 mL). After the organic phases were combined, they were washed with saturated sodium bisulfite (40 mL) and saturated brine (40 mL) successively, dried over anhydrous sodium sulfate, filtered and concentrated, and 4.4 g of compound 1-3-1 as a yellow oil was obtained by column chromatography. The yield was 70%.

[0042] R f (PET / EtOAc=2:1) 0.36; UV(MeOH)λ max =208,321nm; 1 H NMR (400MHz, deuterated chloroform) δ: 3.34 (s, 6H, OCH 3 ), 3.43(s, 3H, OCH 3 ), 3.46(s, 3H, OCH 3 )...

Embodiment 2

[0044] Example 2: Compound 1-3-2(1-(2,4,6-trimethoxymethoxyphenyl)-3-(3,4-dimethoxymethoxy-5-ethoxyphenyl) ) Preparation of propylene ketone):

[0045]

[0046] R f (PET / EtOAc=2:1) 0.40; UV(MeOH)λ max =210,325nm; 1 H NMR (400MHz, deuterated chloroform) δ: 1.39 (t, J=7.2Hz, 3H, CH 3 ), 3.34(s, 6H, OCH 3 ), 3.43(s, 3H, OCH 3 ), 3.46(s, 3H, OCH 3 ), 3.56(s, 3H, OCH 3 ), 4.02(q, J=7.2Hz, 2H, CH 2 ), 5.06(s, 4H, OCH 2 O), 5.11(s, 4H, OCH 2 O), 5.14(s, 2H, OCH 2 O), 6.51 (s, 2H, H-3', 5'), 6.74 (d, J = 1.6 Hz, 1H, H-2), 6.80 (d, J = 16.0 Hz, 1H, H-α), 6.91 (d, J = 1.6 Hz, 1H, H-6), 7.17 (d, J = 16.0 Hz, 1H, H-β); ESI-MS: 553 (M+1) + .

Embodiment 3

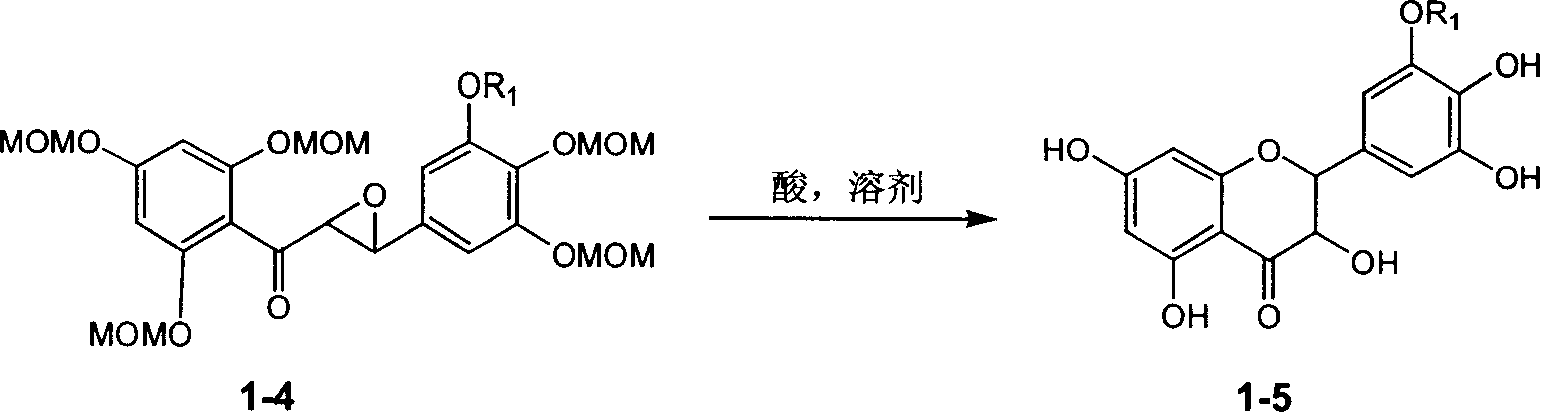

[0047] Example 3: Compound 1-4-1(1-(2,4,6-trimethoxymethoxyphenyl)-3-(3-methoxy-4,5-dimethoxymethoxyphenyl ) Preparation of epoxy acetone):

[0048]

[0049] 3 g of compound 1-3-1 was dissolved in 50 ml of methanol, and while stirring, 4 mL of 2N sodium hydroxide and 4 mL of 30% hydrogen peroxide were added, and stirred at room temperature for 10 hours. The solvent was evaporated under reduced pressure, and 50 mL of water and acetic acid were added. Ethyl extraction (3×30 mL). The organic phases were combined, washed with saturated brine (40 mL), and dried over anhydrous sodium sulfate. It was filtered and concentrated to obtain 2.6 g of yellow oil with a yield of 85%, which can be directly used in the next reaction.

[0050] R f (PET / EtOAc=2:1) 0.37; UV(MeOH)λ max =205,278nm; 1 H NMR (400MHz, deuterated chloroform) δ: 3.34 (s, 6H, OCH 3 ), 3.43(s, 3H, OCH 3 ), 3.46(s, 3H, OCH 3 ), 3.56(s, 3H, OCH 3 ), 3.87(s, 3H, OCH 3 ), 3.89(d, J=1.6Hz, 1H, H-β), 3.93(d, J=1.6Hz, 1H, H-α), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com